Incense burner

A technology of aromatherapy and furnace body, which is applied in the fields of air purification and daily necessities, which can solve the problems of not being able to be better utilized, the heating area of the heat conduction plate is small, and it is not easy to manage and carry, and achieve a long fragrance retention time and reduce Tar and smoke amount, raw material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

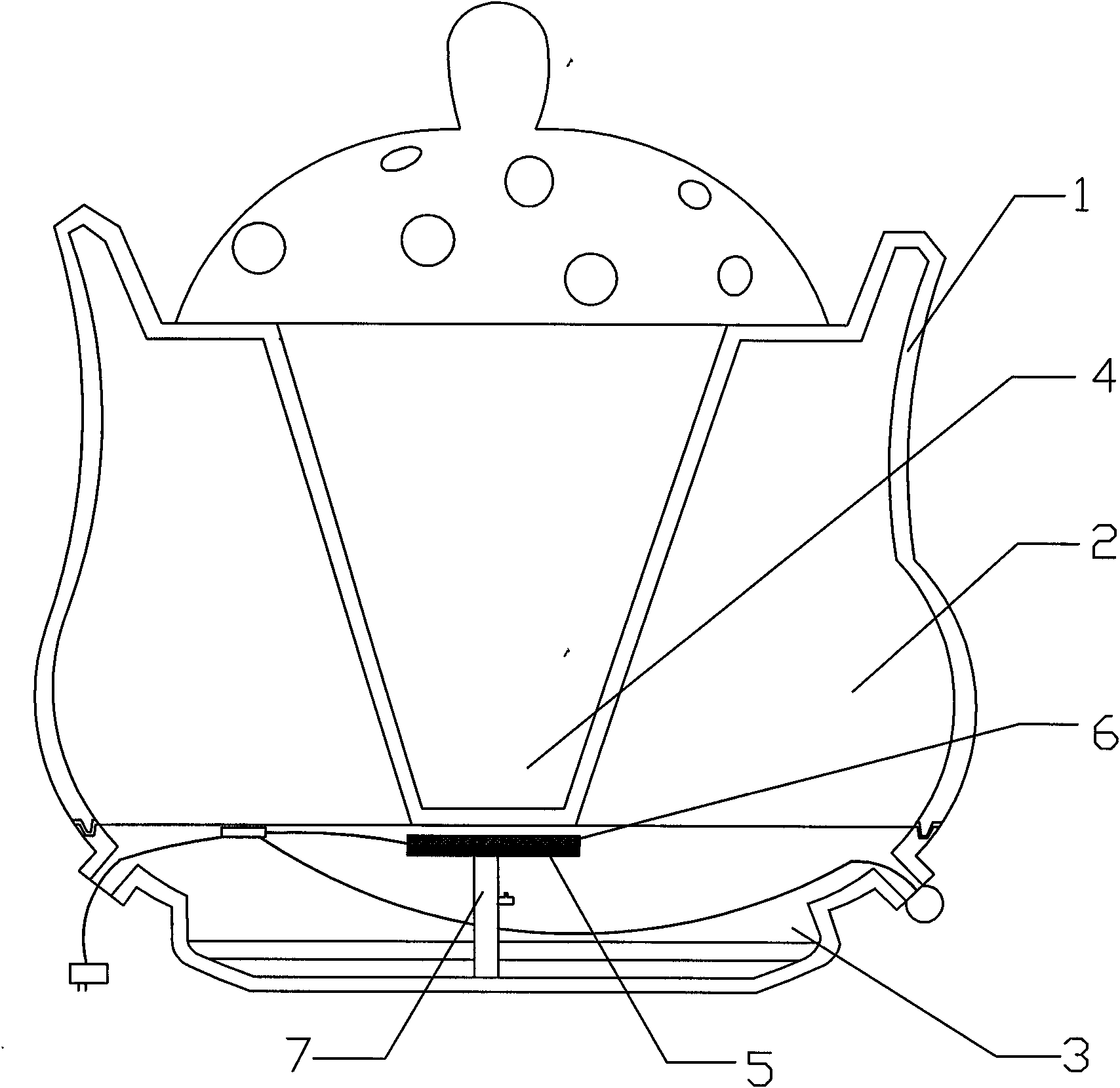

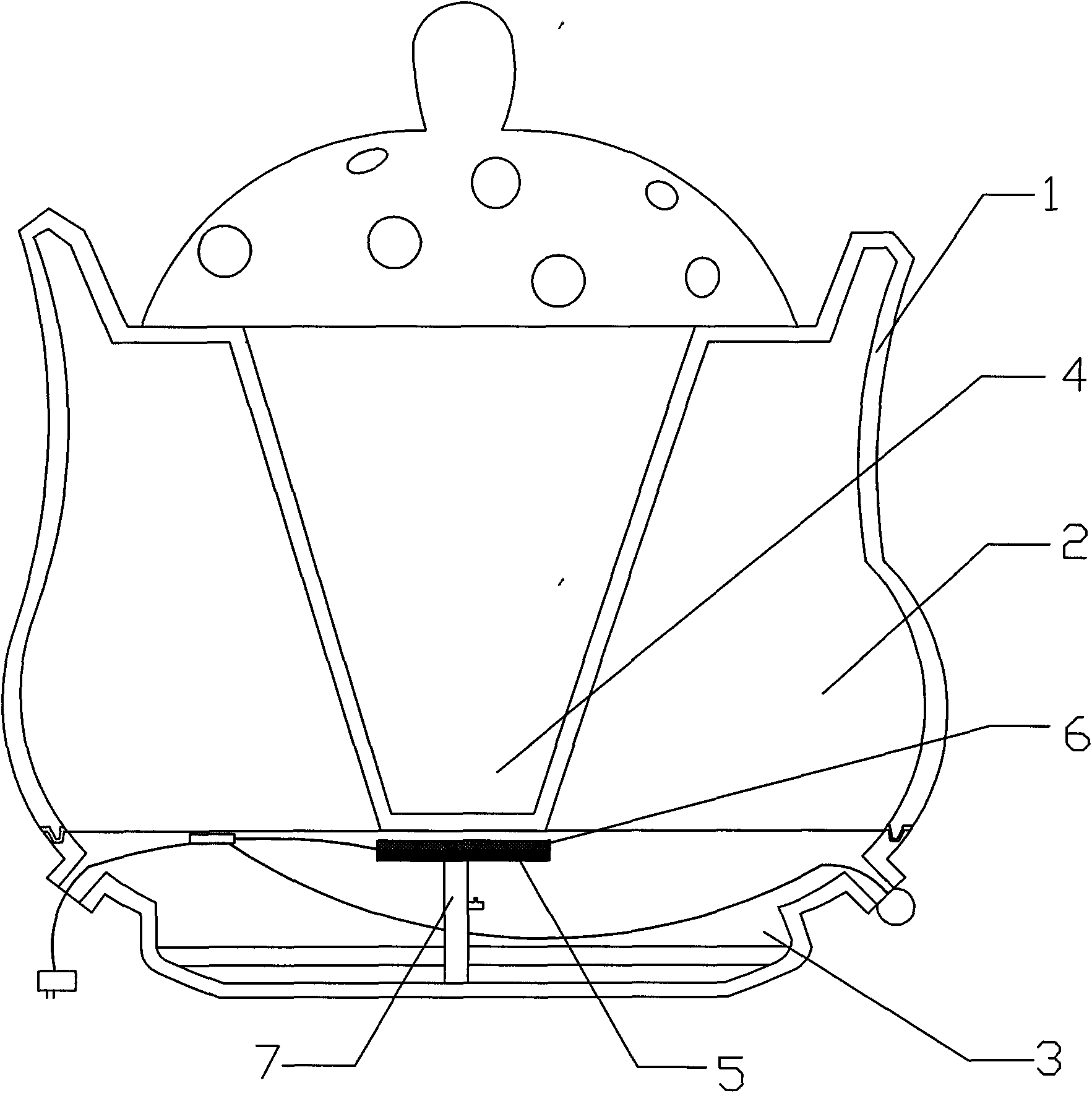

[0020] The structure schematic diagram of a kind of aromatherapy burner of the present invention is as figure 1 As shown, it is mainly composed of a furnace body 1 and a furnace cover with an air outlet. The furnace body 1 includes a hollow pottery or porcelain furnace belly 2 and a tray-shaped furnace buckled under the furnace belly 2. The bottom 3, wherein the furnace belly 2 is a double-layer cavity structure with a lower opening, the furnace belly 2 is M-shaped as a whole, the inner layer is recessed downward to form a material trough 4, and the outer layer protrudes outward to form a furnace-shaped outer wall; The inside of the bottom 3 is equipped with a heat insulating sheet 5 and a heat generating sheet 6, wherein the heat insulating sheet 5 is connected to the furnace bottom 3, and the heating sheet 6 is connected to an external power supply through a wire and stacked on the top of the heat insulating sheet 5; 2. The lower opening matches the installation structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com