Eccentric ring hammer coal crusher

An eccentric ring and hammer crushing technology, applied in grain processing and other directions, can solve the problem of short service life, and achieve the effect of prolonging the service life and avoiding destructive damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

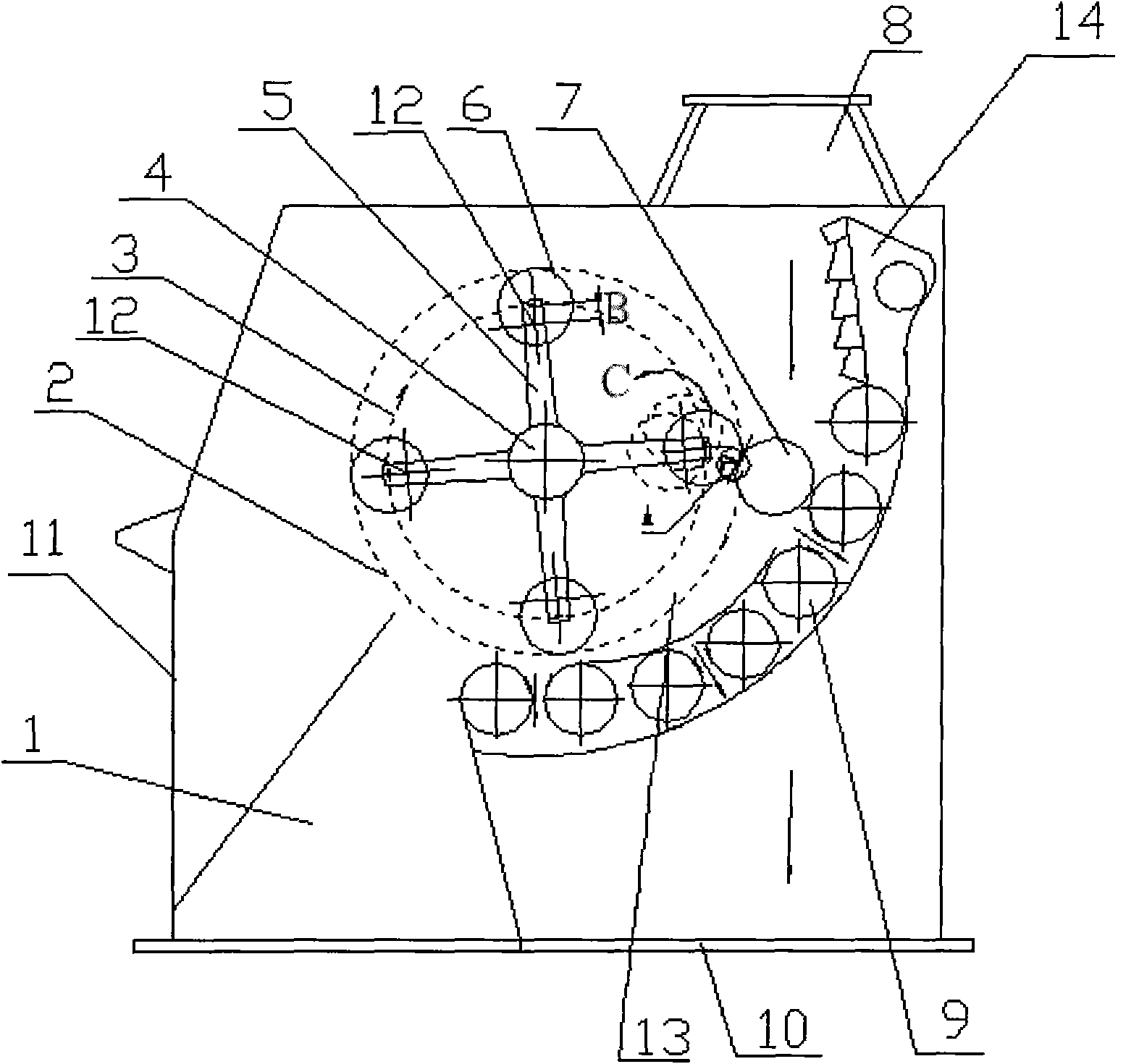

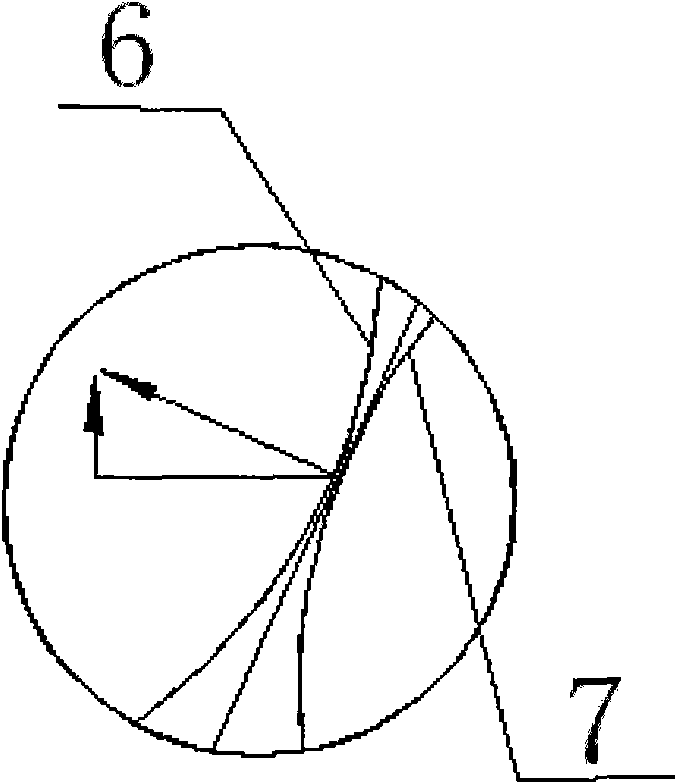

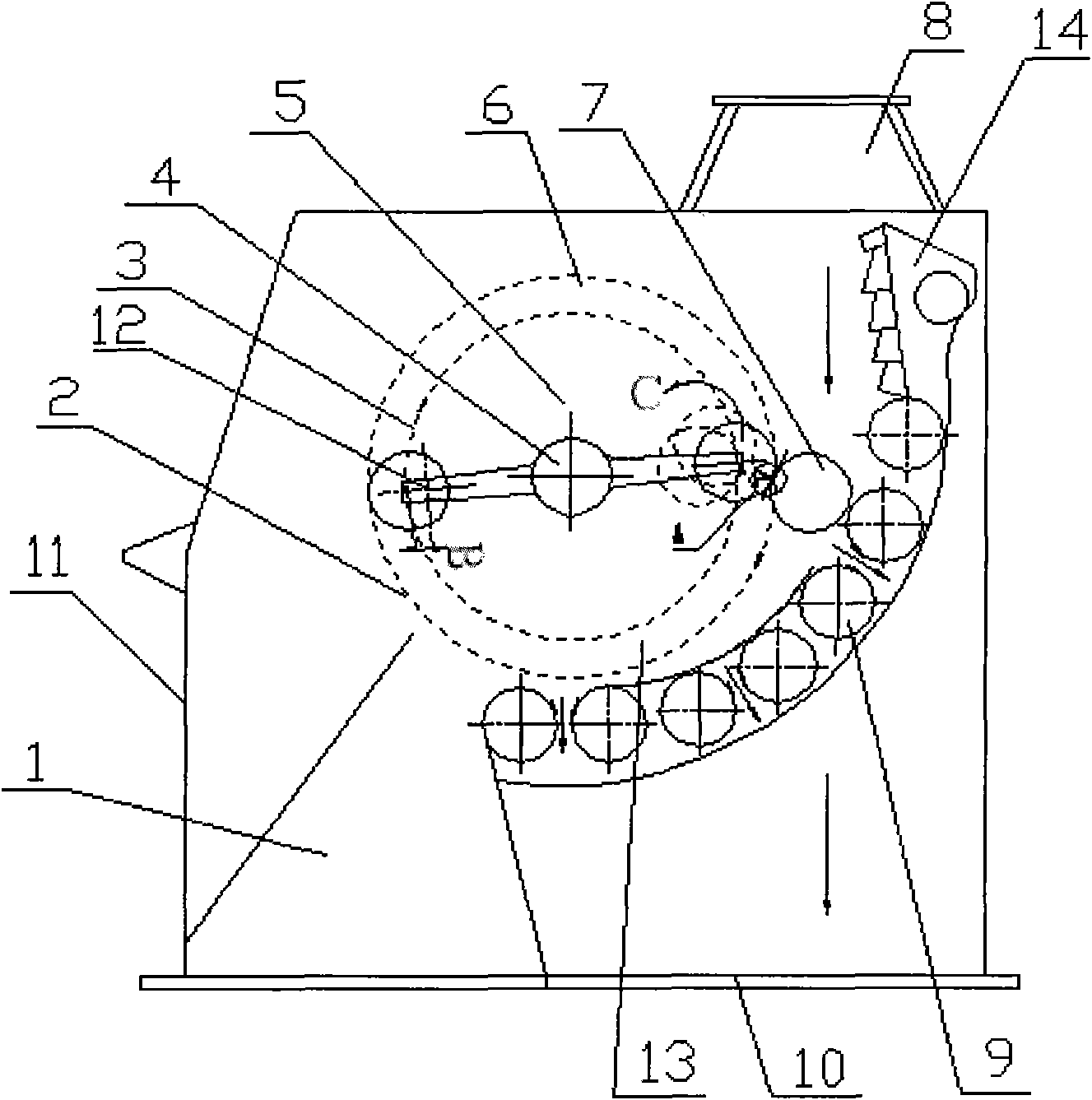

[0023] Such as image 3 As shown, an eccentric ring hammer crusher includes a feed inlet 8 arranged on the upper part of the casing 11, a casing 11, a rotor inside the casing, a rotor counter-attack plate and a screening device, and a discharge port at the lower part of the casing. 10. The recycling port 1 and the power unit on the side of the casing, the rotor includes the rotating shaft 4 installed on the casing 11, the cross-shaped support seat 5 installed on the rotating shaft 4 and the ring hammer 6 eccentrically installed on the support seat 5, The ring hammer installation center 12 and its geometric center form an eccentricity B, and the eccentricity B is 50mm, and the rotation center of the ring hammer is coaxial with the center of the support seat. The screening device is formed by counter-rollers composed of toothed sticks 9. The toothed sticks 9 are set in pairs and installed in the oblong holes on the casing 11, so as to adjust the distance between the toothed stic...

Embodiment 2

[0026] Such as figure 1 As shown, an eccentric ring hammer crusher includes a feed port 3 arranged on the upper part of the casing 11, a casing 11, a rotor inside the casing, a rotor counter-attack plate and a screening device, and a discharge port at the lower part of the casing. 10. The recycling port 1 and the power unit on the side of the casing, the rotor includes the rotating shaft 4 installed on the casing 11, the cross-shaped support seat 5 installed on the rotating shaft 4 and the ring hammer 6 eccentrically installed on the support seat 5, The ring hammer installation center 12 and its geometric center form an eccentricity B, and the eccentricity B is 10-100mm, and the rotation center of the ring hammer is coaxial with the center of the support seat. The screening device is formed by counter-rollers composed of toothed sticks 9. The toothed sticks 9 are set in pairs and installed in the oblong holes on the casing 11, so as to adjust the distance between the toothed s...

Embodiment 3

[0030] Such as figure 1 As shown, an eccentric ring hammer crusher includes a feed port 3 arranged on the upper part of the casing 11, a casing 11, a rotor inside the casing, a rotor counter-attack plate and a screening device, and a discharge port at the lower part of the casing. 10. The recycling port 1 and the power unit on the side of the casing, the rotor includes the rotating shaft 4 installed on the casing 11, the cross-shaped support seat 5 installed on the rotating shaft 4 and the ring hammer 6 eccentrically installed on the support seat 5, The ring hammer installation center 12 and its geometric center form an eccentricity B, and the eccentricity B is 100mm, and the rotation center of the ring hammer is coaxial with the center of the support seat. The screening device is formed by counter-rollers composed of toothed sticks 9. The toothed sticks 9 are set in pairs and installed in the oblong holes on the casing 11, so as to adjust the distance between the toothed stic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com