Automatic bearing inside diameter detector

An automatic detection and bearing inner ring technology, applied in instruments, measuring devices, sorting, etc., can solve the problems of high cost, difficulty in ensuring reliability, low efficiency of bearing inner diameter detection, etc., and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

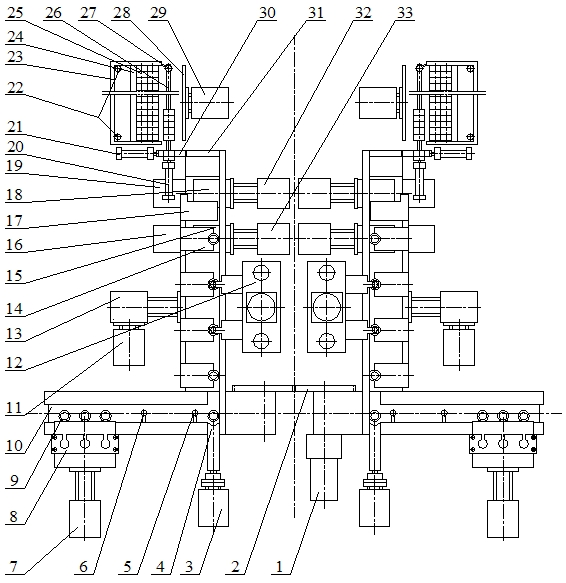

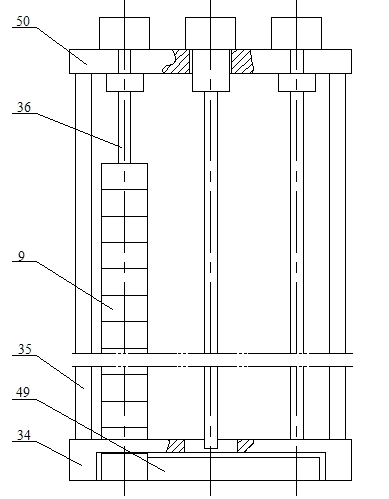

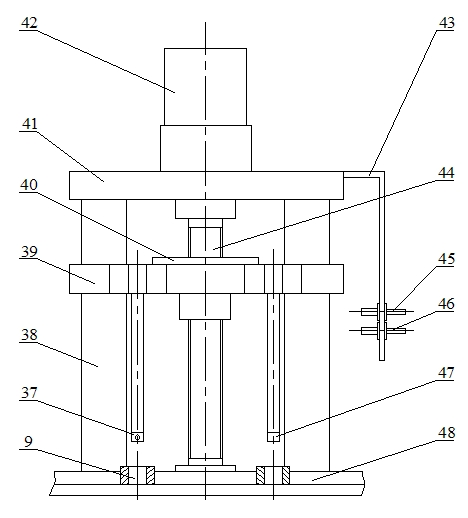

[0016] Such as figure 1 , Figure 4 As shown, the inner ring 9 of the bearing to be inspected is installed on the inlet distribution mechanism 8, and the inlet distribution mechanism 8 can push the inner ring 9 of the bearing to be inspected onto the conveyor belt 10 with a certain beat, and the left and right conveyor belts 10 are driven by the conveyor belt motor 1 Driven by the meshing gear set 2, the feed detection switch 6 and the lack of material detection switch 5 are arranged above the conveyor belt 10, the feed detection switch 6 and the lack of material detection switch 5 are fixed on the equipment base on the side of the conveyor belt 10, and the feed cylinder 3 is fixed on the On the equipment base on the side of the conveyor belt 10, a feed rod 4 is fixed on the piston rod of the feed cylinder 3, and the feed rod 4 is close to the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com