Method for producing oriented high-silicon steel cold-rolled sheet by using directional solidification plate blank

A technology of directional solidification and cold rolling of thin plates, which is applied in chemical instruments and methods, metal rolling, manufacturing tools, etc., can solve the problems of complex process, difficulty of high silicon steel, long process production cycle, etc., achieve process simplification, improve efficiency, The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Re-melt the high-silicon steel ingot containing 5% silicon and 60ppm boron, and use directional equipment for directional solidification. Columnar crystals grow along the direction. The melt temperature is 1480°C and the temperature gradient is controlled at 70K / cm. Typical Metallographic structure such as figure 1 , The thickness of the solidified slab is 5mm.

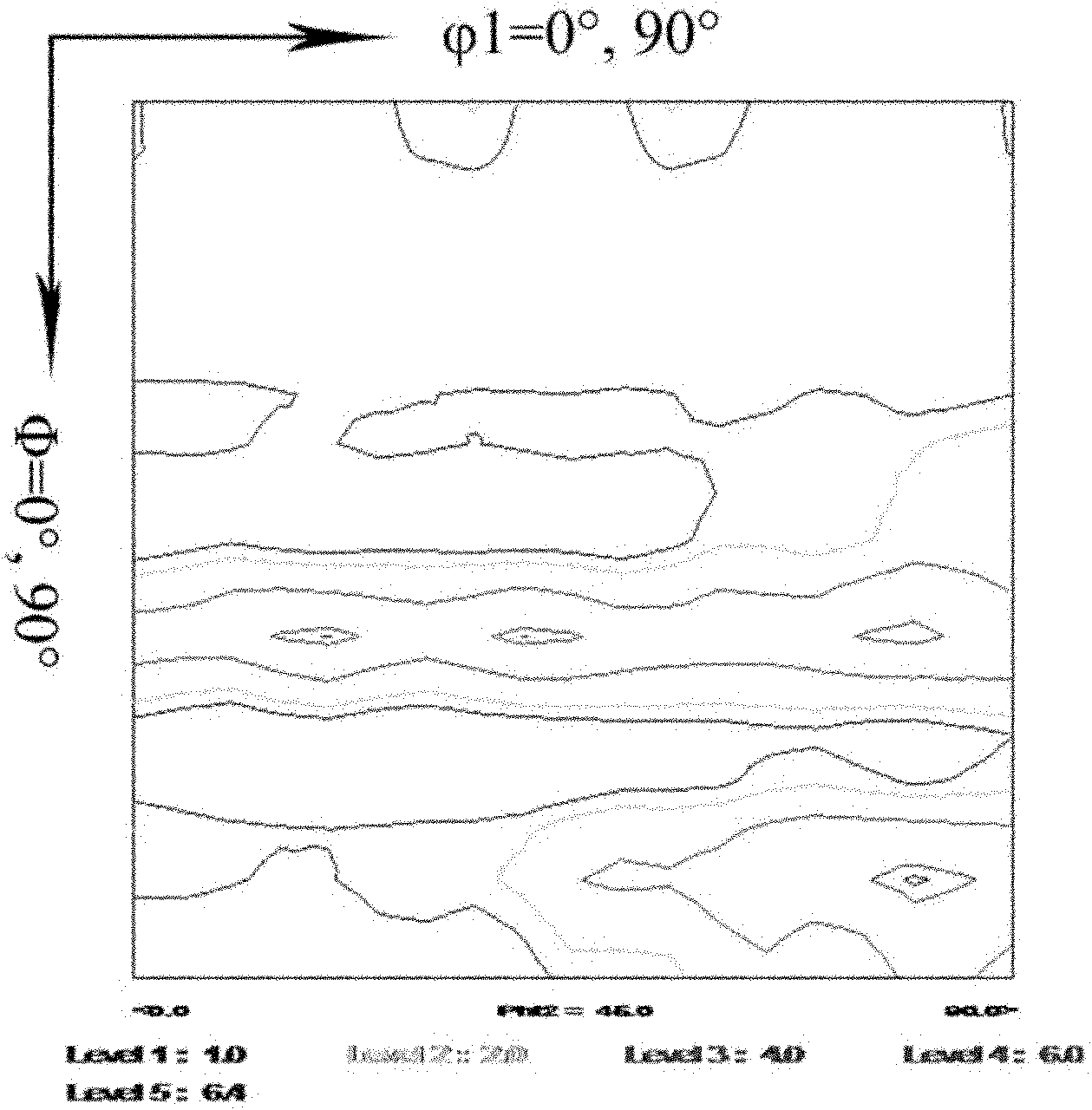

[0018] The surface of the slab is pretreated and rolled at a low temperature. The starting rolling temperature is 500°C, the final rolling temperature is 200°C, the reduction in each pass is 15%, the final warm rolling thickness of the slab is 1.5mm, and the total reduction rate is 70%; figure 2 45° ODF diagram of the thin plate after warm rolling.

[0019] The warm-rolled sheet is pickled and surface-polished, and then cold-rolled at room temperature. The reduction in the first pass is 60%, and the reduction in the second pass is 20%. After that, the cold-rolling is repeated until the thickness reaches 0....

Embodiment 2

[0022] Re-melt the high-silicon steel ingot containing 6.5% silicon and 1500ppm boron, and use directional equipment for directional solidification. Columnar crystals grow along the direction. The melt temperature is 1530°C and the temperature gradient is controlled at 200K / cm. After solidification The slab thickness is 15mm.

[0023] The surface of the slab is pretreated and rolled at a low temperature. The starting rolling temperature is 700°C, the final rolling temperature is 200°C, the reduction in each pass is 20%, the final warm rolling thickness of the slab is 2.0mm, and the total reduction rate is 87%;

[0024] The warm-rolled sheet is pickled and surface-polished, and then cold-rolled at room temperature. The reduction in the first pass is 10%, and the reduction in the second pass is 8%. After that, the cold-rolling is repeated until the thickness reaches 0.3mm.

[0025] Then, the surface of the cold-rolled sheet is treated and annealed for secondary recrystallizati...

Embodiment 3

[0027] Re-melt the high-silicon steel mother ingot with 8.5% silicon and 2000ppm boron, and use directional equipment for directional solidification. Columnar crystals grow along the direction. The melt temperature is 1590°C and the temperature gradient is controlled at 300K / cm. After solidification The slab thickness is 10mm.

[0028] The surface of the slab is pretreated and rolled at a low temperature. The starting rolling temperature is 900°C, the final rolling temperature is 400°C, the reduction per pass is 15%, the final warm rolling thickness of the slab is 1.5mm, and the total reduction rate 85%;

[0029] The warm-rolled sheet is pickled and surface-polished, then cold-rolled at room temperature, with a reduction of 30% in the first pass and a reduction of 20% in the second pass, and then repeated cold-rolling until the thickness reaches 0.3mm.

[0030] Then, the surface of the cold-rolled sheet is treated and annealed for secondary recrystallization to obtain an ori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap