Helical hole-milling device and method based on numerical control machine

A CNC machine tool and helical milling technology, which is applied in the direction of driving device, feeding device, milling machine equipment, etc., can solve the problems of residual error and affecting the precision of hole making, and achieve the increase of adjustable range, improve the precision of hole making, and facilitate automatic lock effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

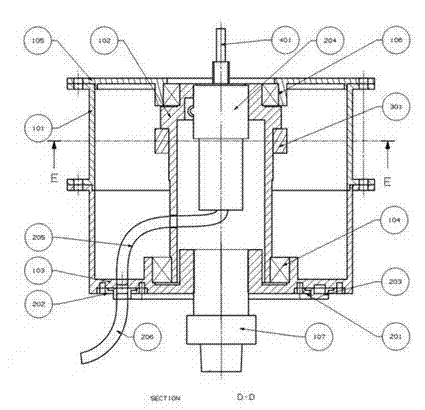

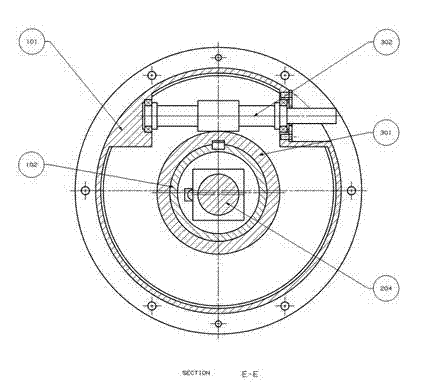

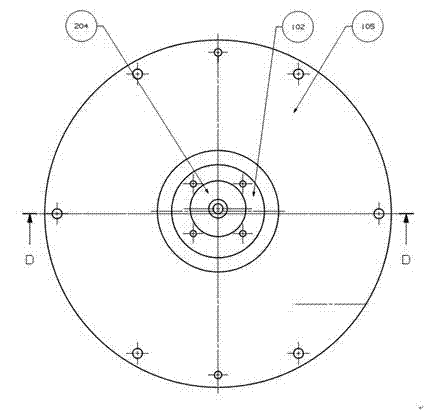

[0019] The present invention is a helical milling hole method and device based on a numerically controlled machine tool. The device is mainly installed on a numerically controlled machine tool by using a processed knife handle, and the rotation of the main shaft of the numerically controlled machine tool is used for the revolution in the helically milled hole, and The feed is provided by the CNC machine tool, and the device itself provides the rotation of the tool and the adjustment of the offset. In this way, when the machine tool spindle rotates at a slow speed, the machining tool will revolve around the axis of the machine tool spindle, and cooperate with the feed of the machine tool spindle to finally realize a The tool can perform helical milling operations on various hole diameters. The specific implementations of the method and device of the present invention will be described in detail below.

[0020] figure 1 The invention discloses a helical milling method and devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com