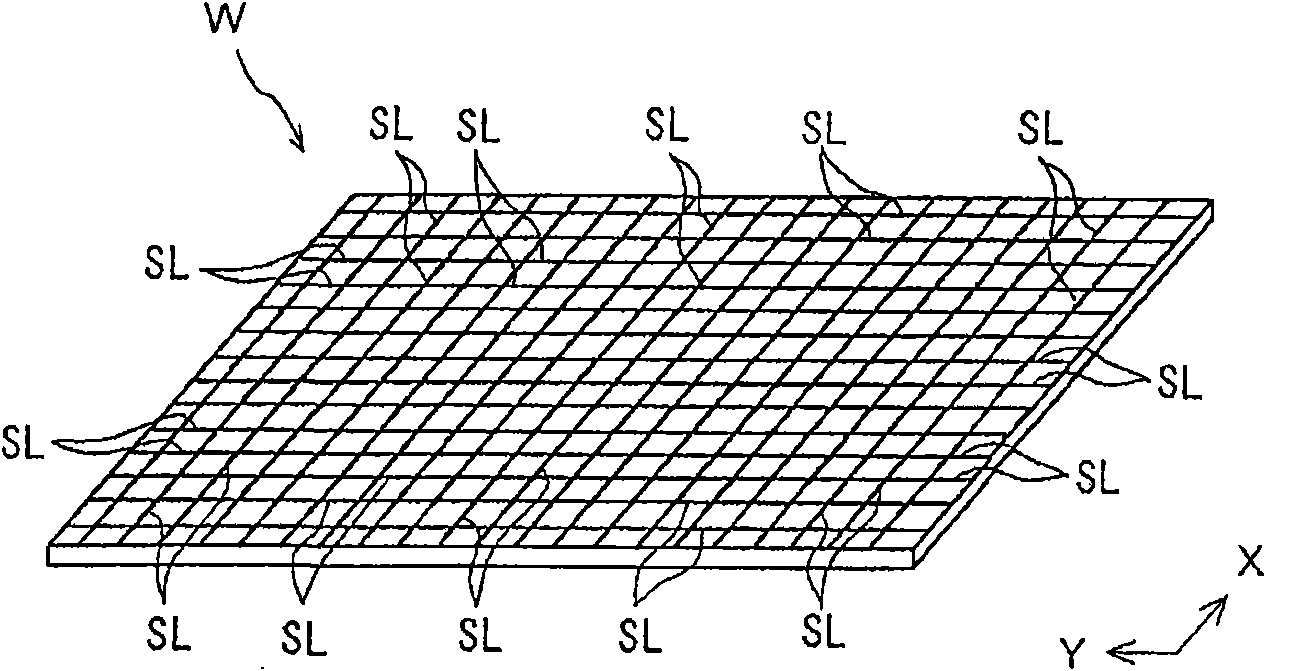

Laser scribing method and device

A laser scribing and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as unfavorable cost and complicated equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

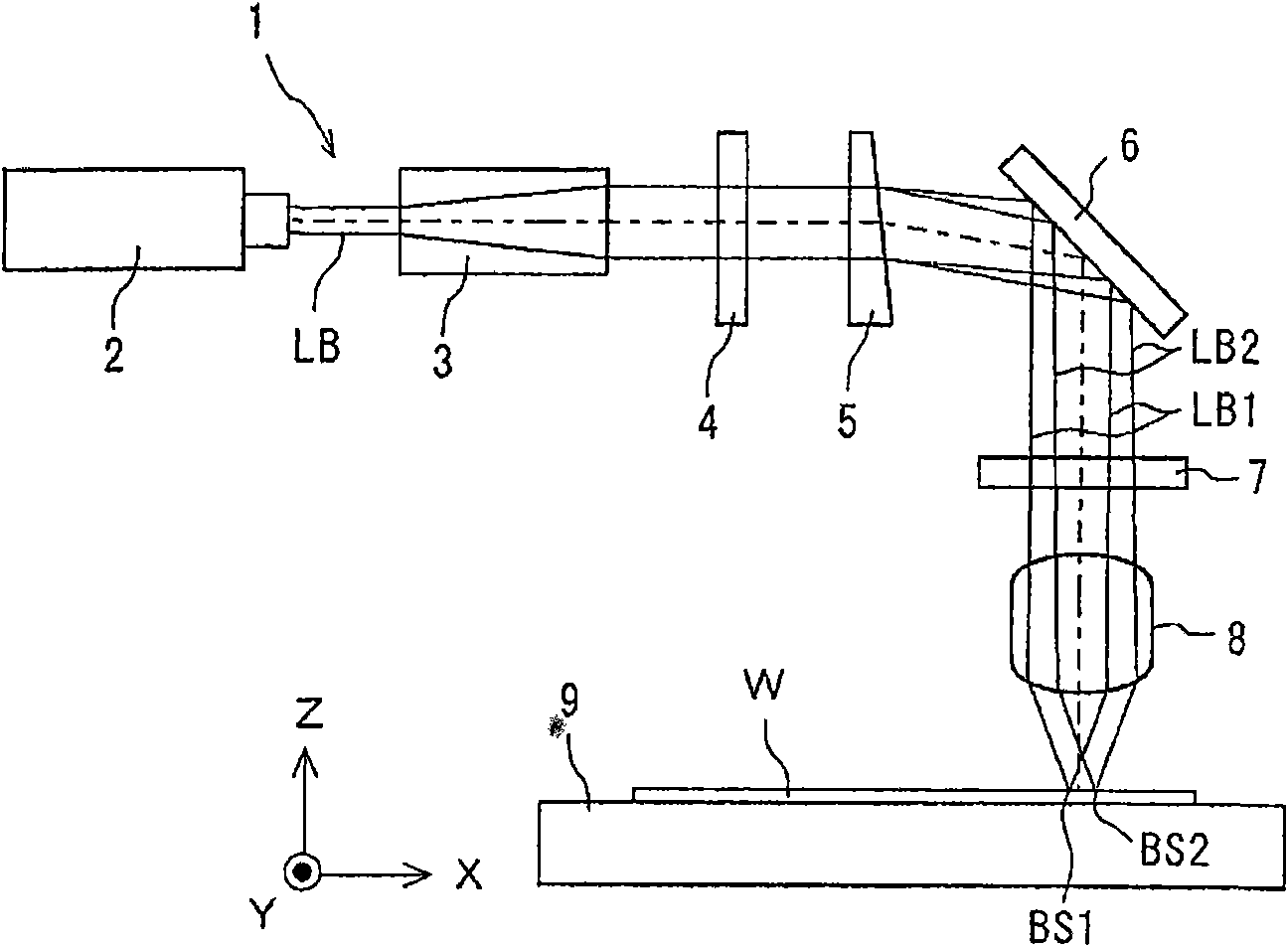

[0075] In the case of forming a scribed groove on a workpiece using a laser scribing device that splits the laser light emitted from a laser source to form multiple beam spots, the relationship between the out-of-focus position and the depth of the groove was studied. .

[0076] The laser scribing device is used figure 2 In the shown laser scribing device, the components of the 1 / 4 wavelength plate are omitted.

[0077] As a laser source, Nd:YAG laser (wavelength 1064nm, output 10W) was used. The output characteristics of the laser light were set as shown in Table 1.

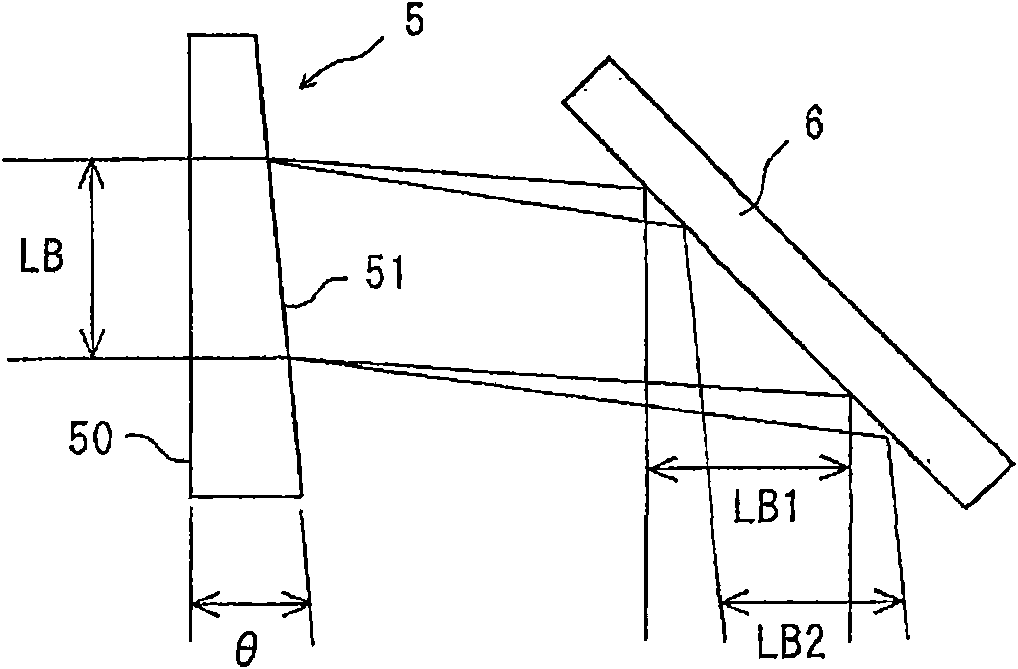

[0078] For the birefringent element, a crystal plate with a wedge angle of 2° is used.

[0079] As the condenser lens, a lens with a focal length f of 50 mm is used.

[0080] The workpiece is made of alumina ceramic with a thickness of 0.28mm.

[0081] The scribing speed (moving speed of the beam spot) SP was set at 50 mm / sec.

[0082] The depth of the scribe groove was measured at points (10 μm pitch) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com