Line scanning CCD camera image correction method based on rotary carrying table and medium

An image correction and line scan technology, applied in image analysis, image data processing, graphic image conversion, etc., can solve problems such as the improvement of factory efficiency, the increase of weak defects, and the economy of missed inspection manufacturers, so as to improve efficiency and shorten the The effect of production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

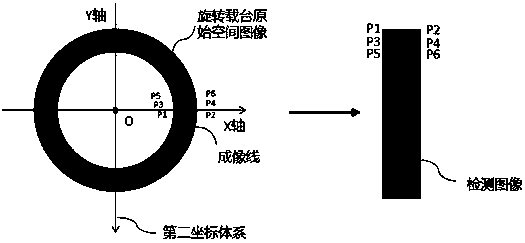

[0044] According to one embodiment of the present invention, a method for correcting images of a line-scan CCD camera based on a rotating stage is provided, including:

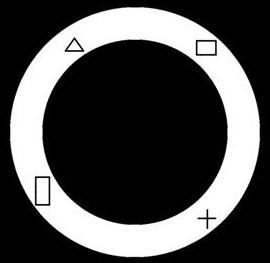

[0045] S1: The rotating stage drives the detection object to rotate. The line-scan CCD camera is located above the rotating stage and the extension line of its imaging line passes through the center of the rotating stage. A detection image of the detection object;

[0046] Further, the scanning area of the line-scan CCD camera is an annular area;

[0047] S2: Establish a first coordinate system with the detection image, and obtain the first coordinate value and gray value of each pixel of the detection object in the first coordinate system;

[0048] S3: Establish a second coordinate system with a circular area, and obtain the second coordinate value of each pixel of the detection object in the second coordinate system; S4: Combine the first coordinate value in the first coordinate system with the first coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com