Flux-cored wire belt type powder feeder

A flux-cored welding wire and belt-type technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems that affect the health of workers, increase the number of uncontrollable links, and affect the stability of filling rate, etc., so as to reduce kinetic energy , less spontaneous, less splashy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

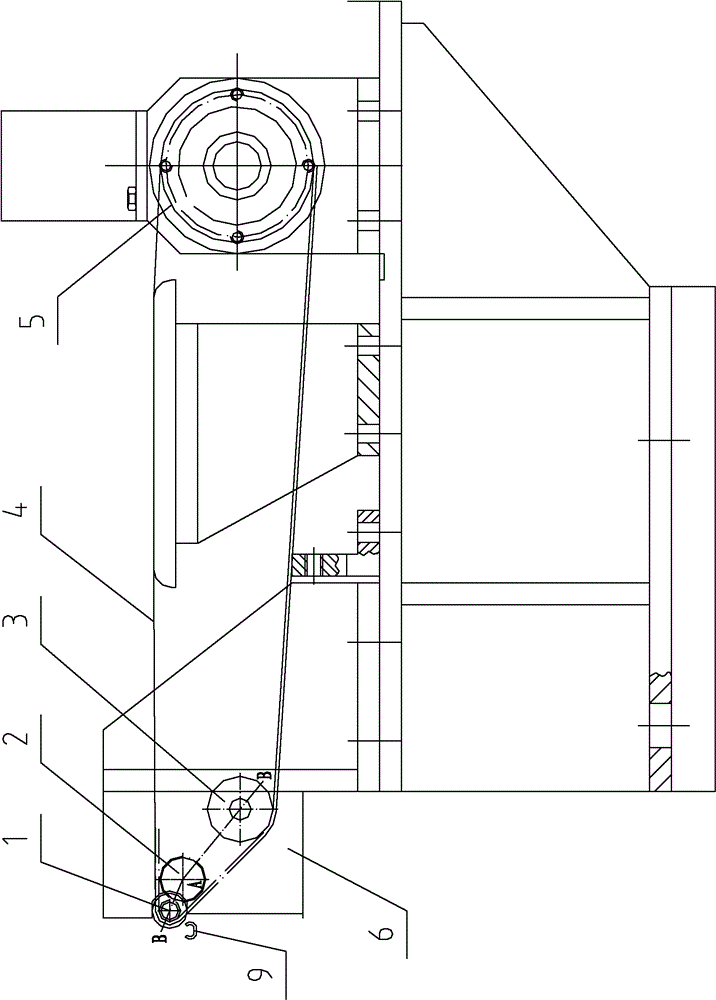

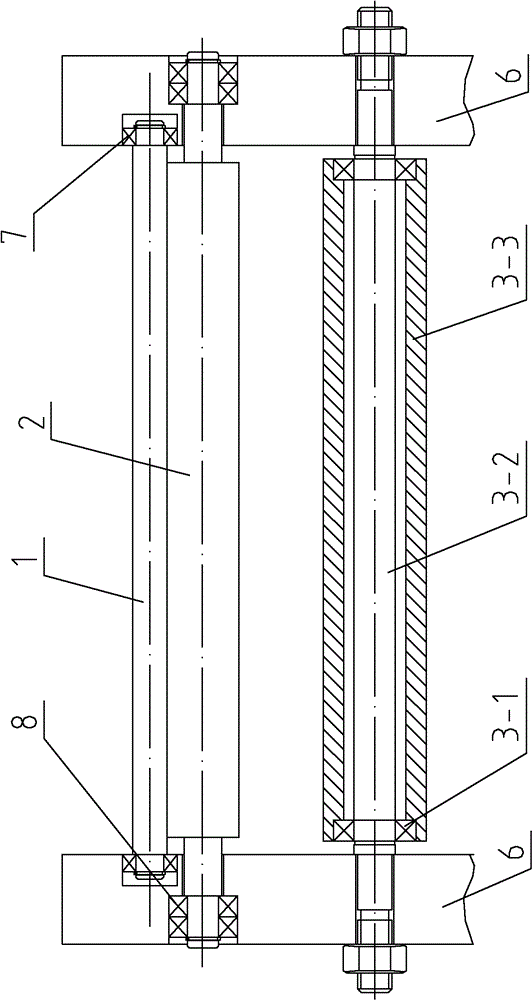

[0024] see Figure 1 ~ Figure 2 , a flux-cored wire belt-type powder feeder, comprising a powder feeding belt 4, a front shaft 1, and a rear shaft 5, the powder feeding belt 4 is tensioned on the front shaft 1 and the rear shaft 5, and the front shaft 1 is installed on the front shaft bracket 6, the powder feeding belt 4 bypasses the front shaft 1 and is frictionally connected with it. Behind the front shaft 1, there is also a support shaft 2 parallel to it. The support shaft 2 is frictionally connected with the front shaft 1, and the support shaft 2 is installed on On the front axle bracket 6. With the above structure, the diameter of the front shaft 1 can be reduced to 10 mm, or even 6 mm, without affecting the tension of the powder feeding belt 4 .

[0025] The two ends of the front axle 1 are respectively provided with first bearings 7, and the first bearings 7 at both ends of the front axle 1 are respectively embedded in mutually parallel slide grooves provided on the fr...

Embodiment 2

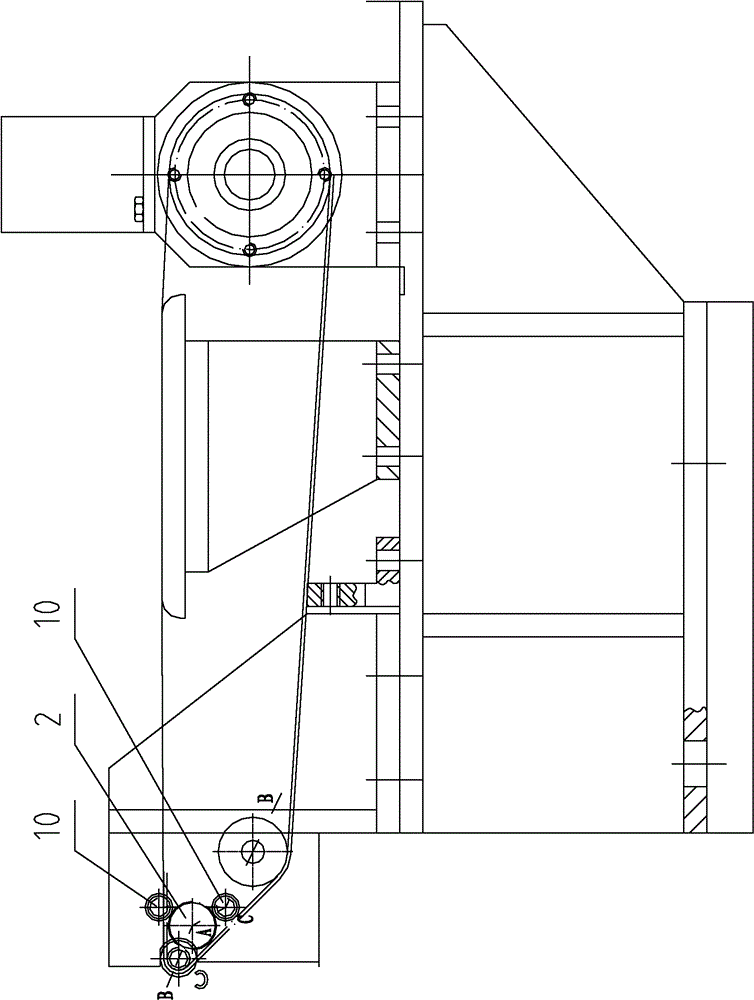

[0029] see Figure 3 ~ Figure 4 , a flux-cored wire belt-type powder feeder, the difference from Embodiment 1 is that the third bearing 11 installed at both ends of the support shaft 2 is fixed by the first screws 10 distributed in its circumferential direction, and the first screws 10 are fixed On the front axle bracket 6. The rest of the structure of the flux-cored wire belt-type powder feeder described in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

Embodiment 3

[0031] see Figure 5 ~ Figure 7 , a flux-cored wire belt-type powder feeder, the difference from Embodiment 1 is that no bearings are installed at both ends of the support shaft 2, and are directly supported by two fourth bearings 12 distributed in the circumferential direction of the end of the support shaft, and the fourth Bearing 12 is installed on the second screw 13 that is affixed with front axle support 6. The two fourth bearings form a second angle with the line connecting the center of the support shaft respectively, the extension line of the line connecting the center of the front axle and the center of the support shaft is located in the range of the second angle, the support shaft 2 is frictionally connected with the fourth bearing 12, and the fourth bearing 12 is installed on the second screw 13 that is affixed with front axle bracket 6. With the above structure, the diameter of the front shaft 1 can be reduced to 4 mm, or even less than 4 mm, without affecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com