Device for putting weft thread band

A yarn piece and weft laying technology, which is applied in textiles and papermaking, flat warp knitting machines, knitting, etc., can solve the problems of complex structure of known devices, achieve the effect of simplifying yarn threading and increasing working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

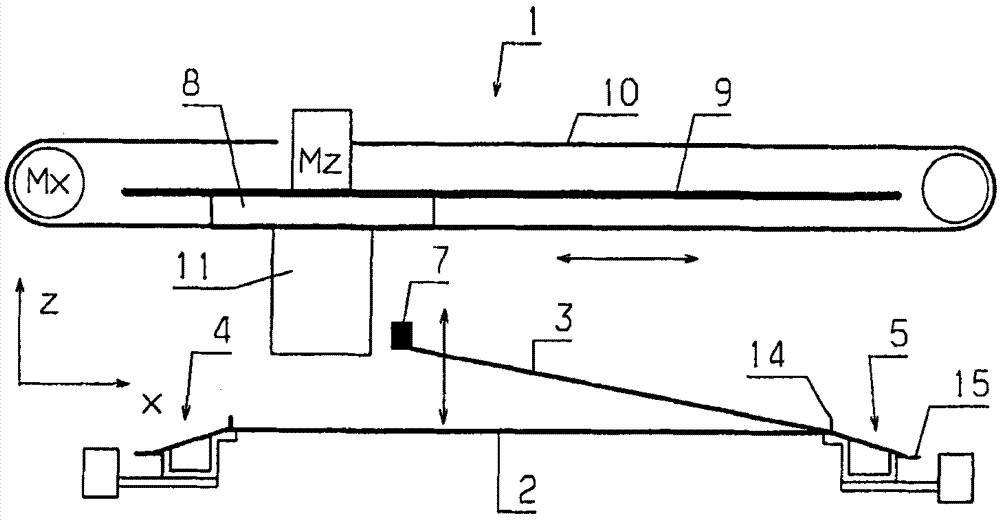

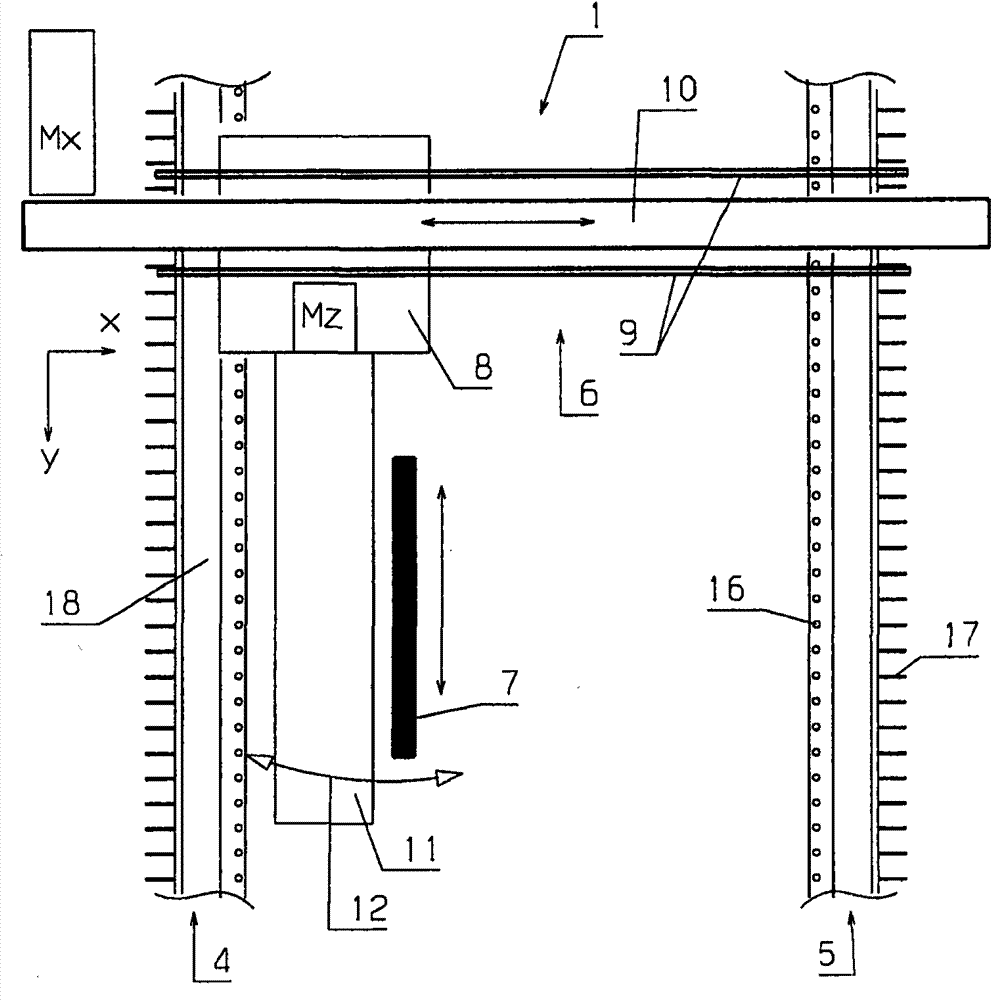

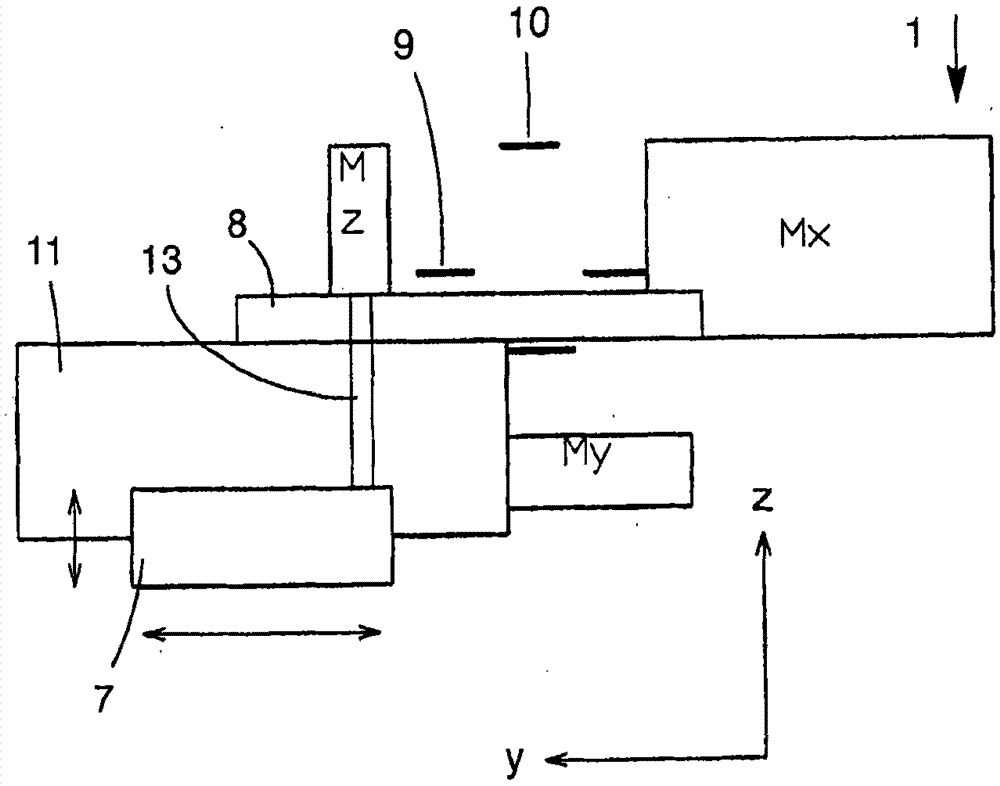

[0022] figure 1 A device 1 for laying weft thread sheets 2 , 3 is shown schematically. The weft thread sheet 2 has been laid between two sheet conveying devices 4 , 5 and is conveyed by the sheet conveying devices 4 , 5 in a conveying direction 6 of a reinforcing device, not shown in detail, eg a knitting device. Conveying direction 6 in figure 1 perpendicular to the plane of the drawing.

[0023] To simplify the description below, the three directions are labeled x, y and z below. The first direction x runs between the two sheet transport devices 4 , 5 . However, this direction does not have to be perpendicular to the conveying direction 6 . The angle between the first direction x and the conveying direction 6 can also be different from 90°. The terms "first", "second" and "third" do not imply that the movements must be performed in the corresponding order.

[0024] The second direction y extends perpendicularly to the first direction x and thus parallel to the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com