Apparatus for detecting particles on a flat glass

A flat glass and foreign matter detection technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of inability to detect, inaccurate detection results, and inability to obtain accurate information, etc., and achieve the effect of reducing adverse phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, preferred embodiments of the foreign matter detection device on a plate glass surface according to the present invention will be described in detail with reference to the drawings.

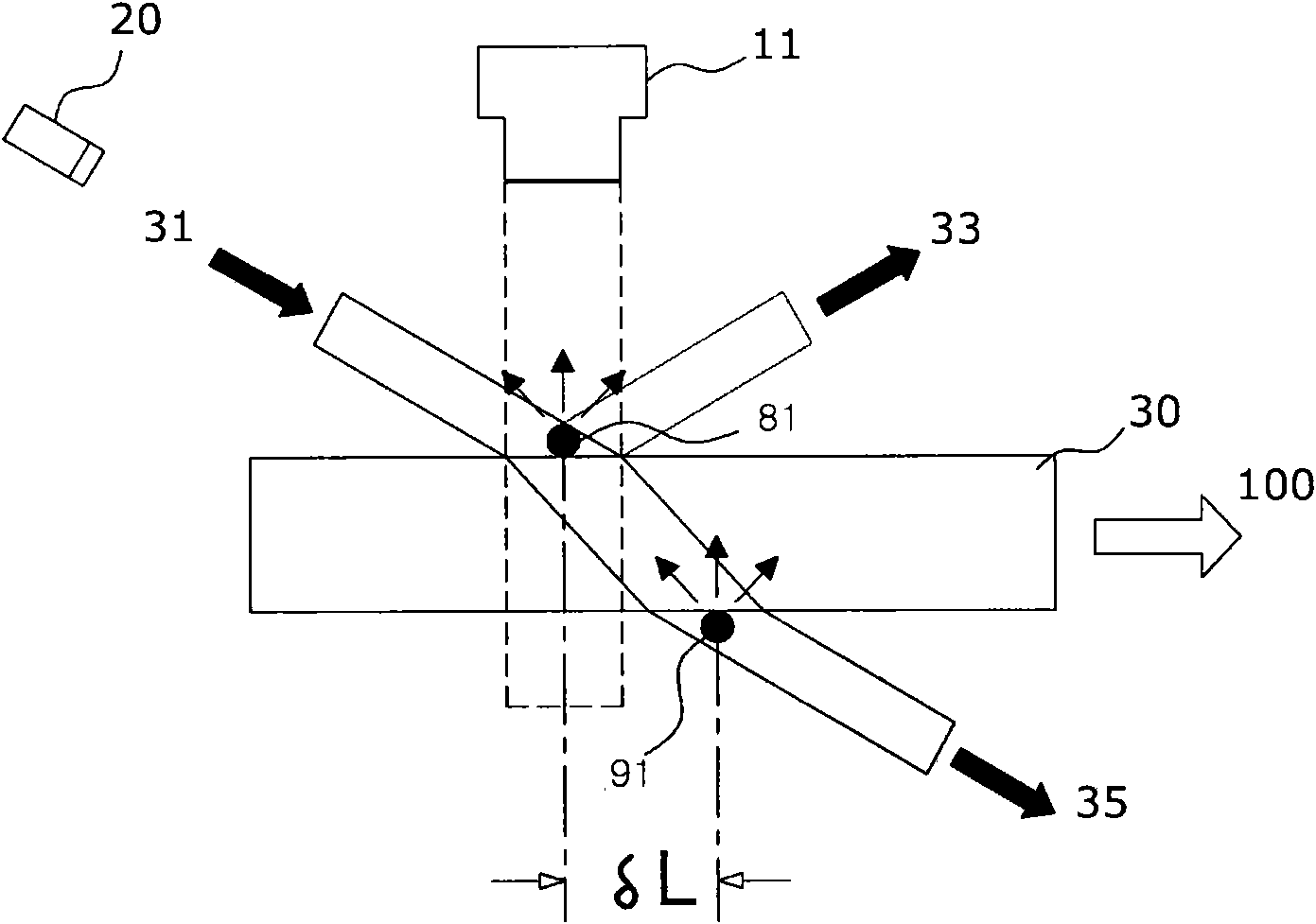

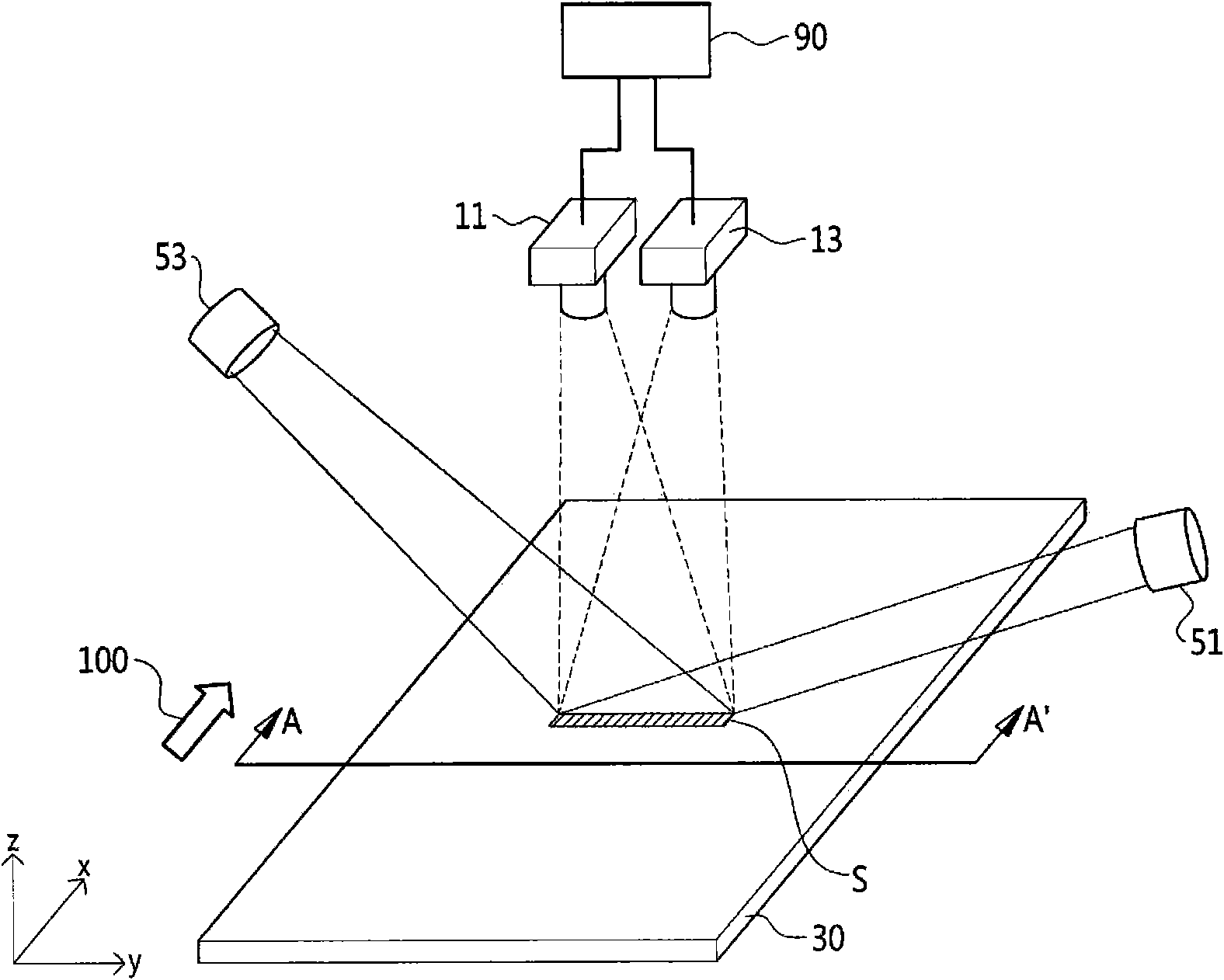

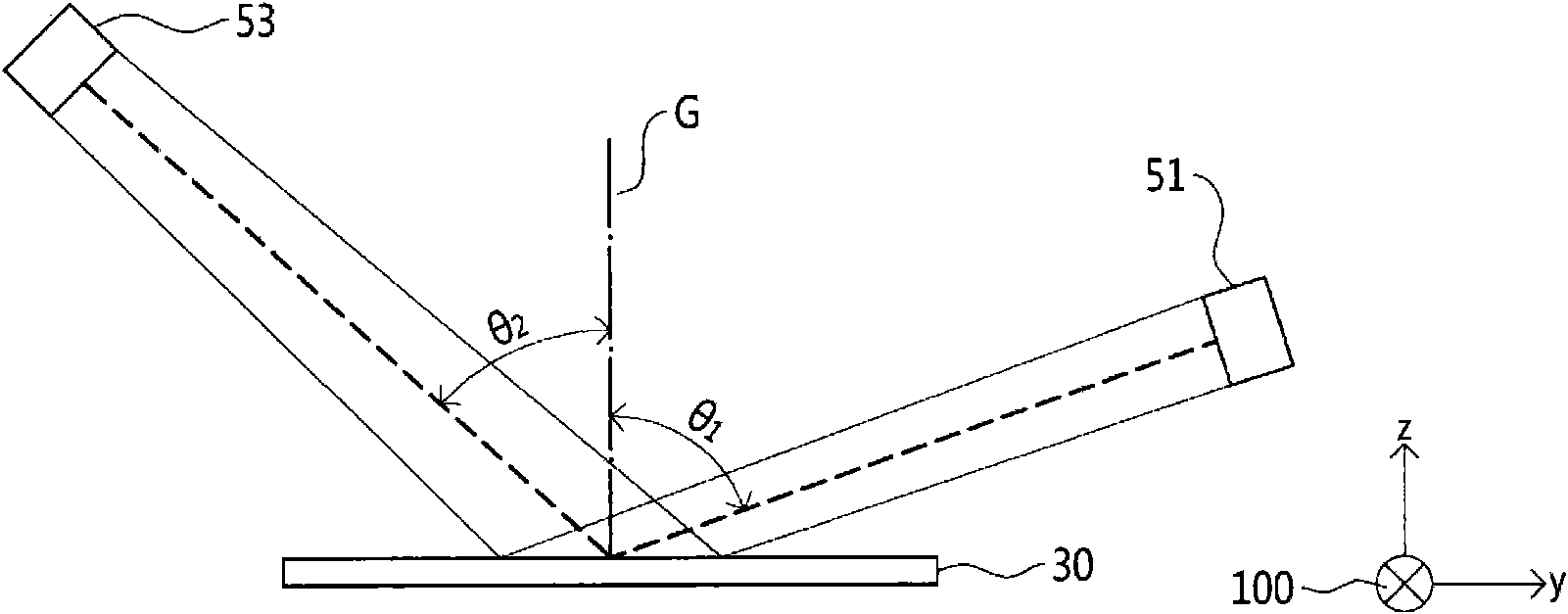

[0062] figure 2 It is a structural diagram schematically showing a preferred embodiment of the foreign matter detection device on the surface of flat glass of the present invention, image 3 yes figure 2 A partial cross-sectional view of the A-A' direction.

[0063] Before the description, one side where the A-side laser beam irradiating device 51 and the B-side laser beam irradiating device 53 are respectively provided is defined as the following meaning: among the four corners of the flat glass substrate 30 formed into a rectangle, the A corner portion at a position parallel to the transfer direction of the glass substrate 30 .

[0064] refer to figure 2 and image 3 , the foreign matter detection device on the flat glass surface of the present invention includes: A-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com