Liquid crystal device, its mfg. method and electronic device

A technology of a liquid crystal device and a manufacturing method, applied in nonlinear optics, instruments, optics, etc., can solve the problems of substrate spacing deviation, contrast reduction, incomplete flatness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

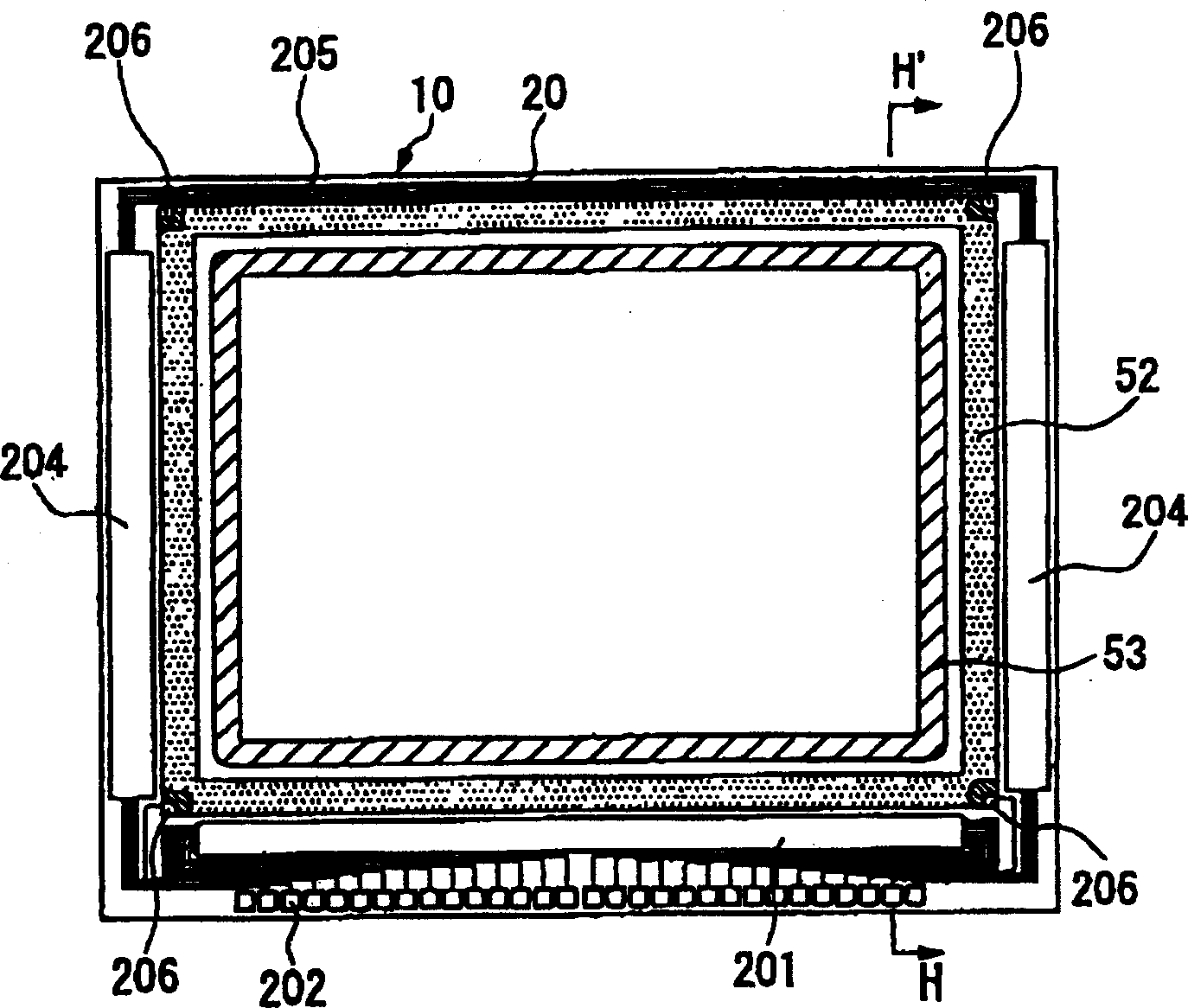

Embodiment 1

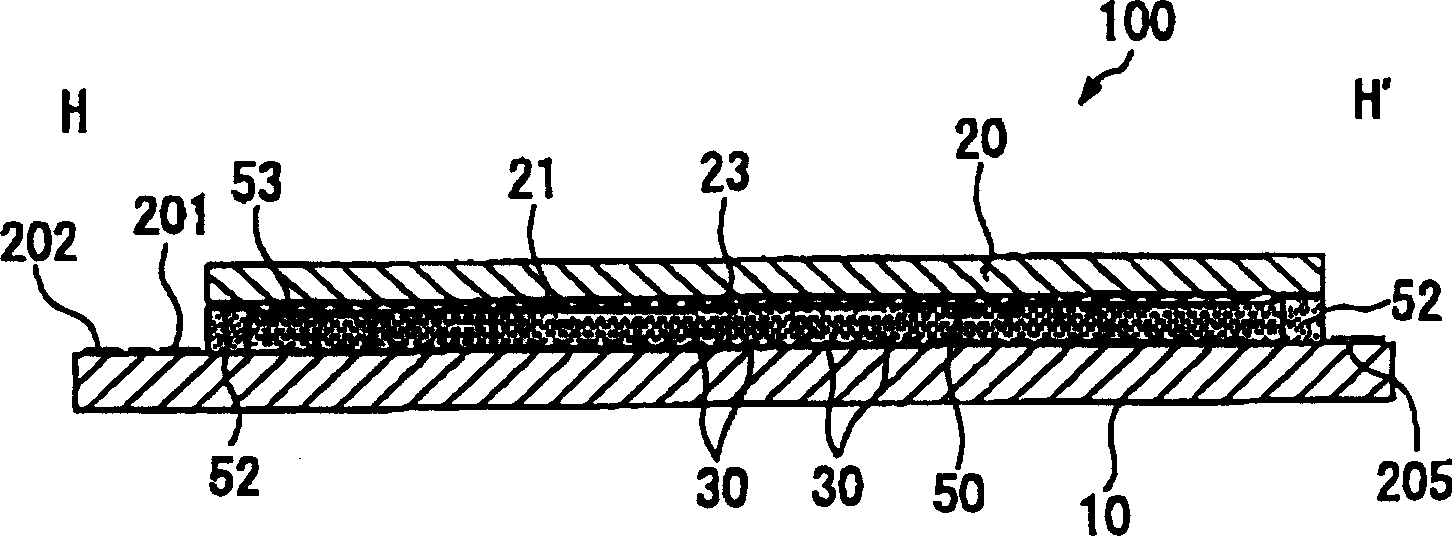

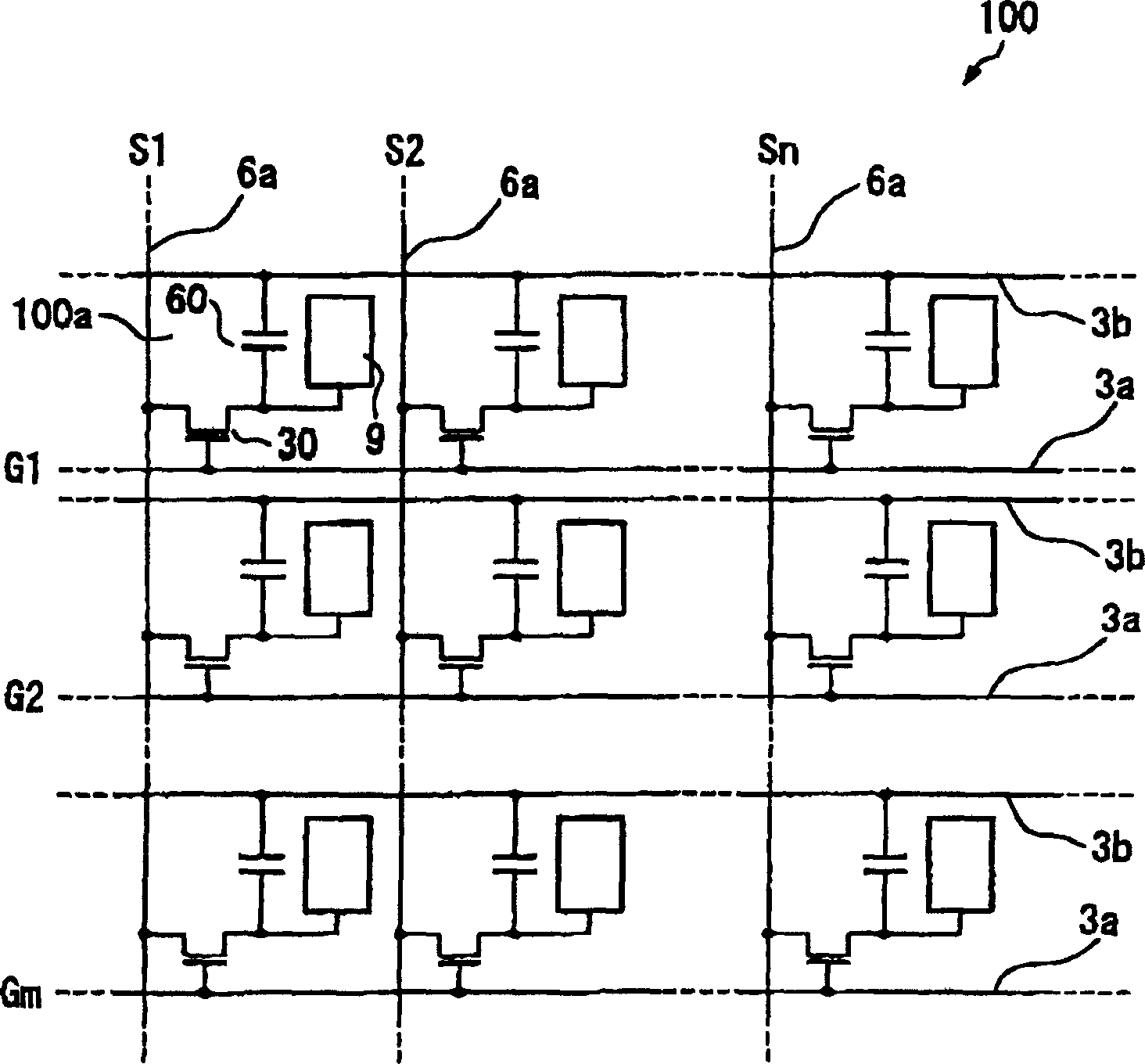

[0065] First, the liquid crystal display device of Example 1 used resin-made spacers 25 having an average particle diameter D=3 μm. Specifically, on a glass substrate (lower substrate) of 370mm×470mm, after using a dispenser, the above-mentioned adhesive was drawn in a closed frame shape, and as shown in Table 1, it was prepared at a density of 80 to 350 pieces / mm 2 The above-mentioned spacers were scattered and heated at 100° C. for 10 minutes to adhere the spacers to the surface of the substrate, and liquid crystal (super twisted nematic) was dropped using a dispenser.

[0066] Then, after attaching the substrate on which the liquid crystal was dropped and the other substrate (upper substrate) and releasing the atmosphere, use an output of 100mW / cm on the surface of the substrate 2 (365nm) high-pressure mercury lamp was used as a UV irradiator for UV irradiation. Next, heat in an oven to completely cure the adhesive. After such curing treatment, the liquid crystal panel is...

Embodiment 2

[0076] The average particle diameter of the spacers used was set at 6 μm, and the same liquid crystal device as in Example 1 above was produced, and the incidence of cell gap defects (Table 5), the incidence of vacuum regions at low temperatures (Table 6), and the occurrence of high-temperature voids were measured. Incidence of defective time box clearance (Table 7). In the same manner as in Example 1, ideal conditions were examined for these cell gap defect occurrence rates, low-temperature vacuum region occurrence rates, and high-temperature cell gap defect occurrence rates, and the measurement results are shown in Table 8. table 5 Table 6 Table 7 Table 8

[0077] From these results, it can be seen that regardless of the specific value of the average particle diameter D of the spacer, in relation to the layer thickness d of the liquid crystal layer, by setting the average particle diameter D and setting the density of the spacer under ideal conditions, the It is pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com