Vehicle door handle unit

A handle and door technology, applied in the direction of the device for tightening the carpet, vehicle locks, vehicle parts, etc., can solve the problem of unavailability, and achieve the effect of preventing abnormal opening of the door and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, typical embodiments of the invention will be described based on the accompanying drawings.

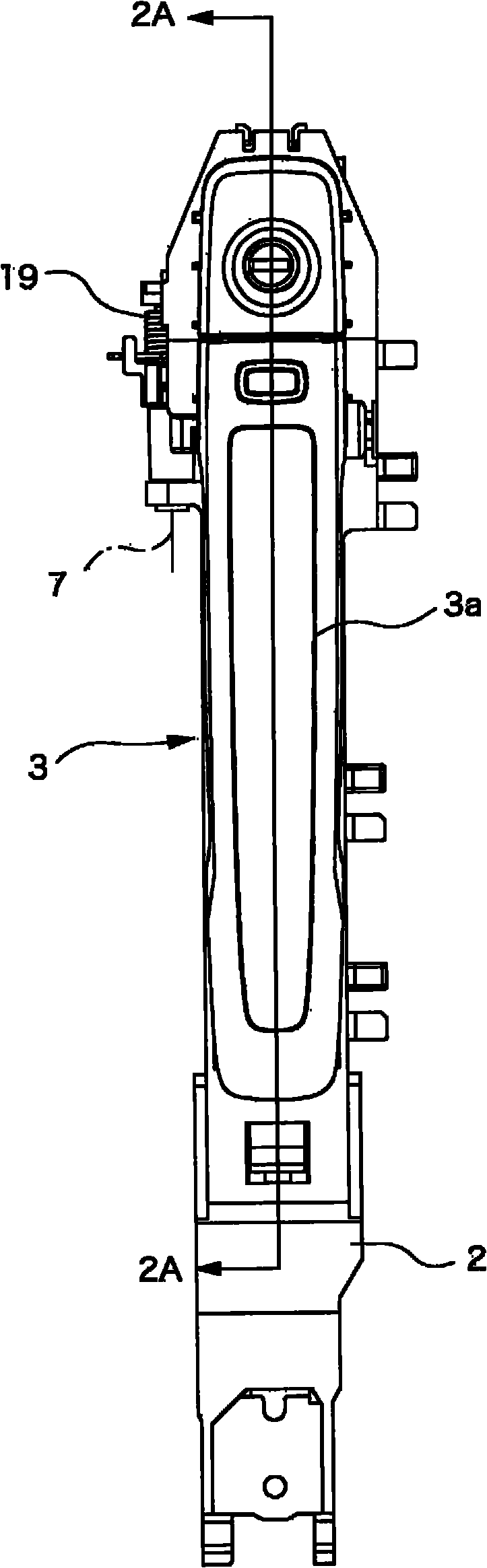

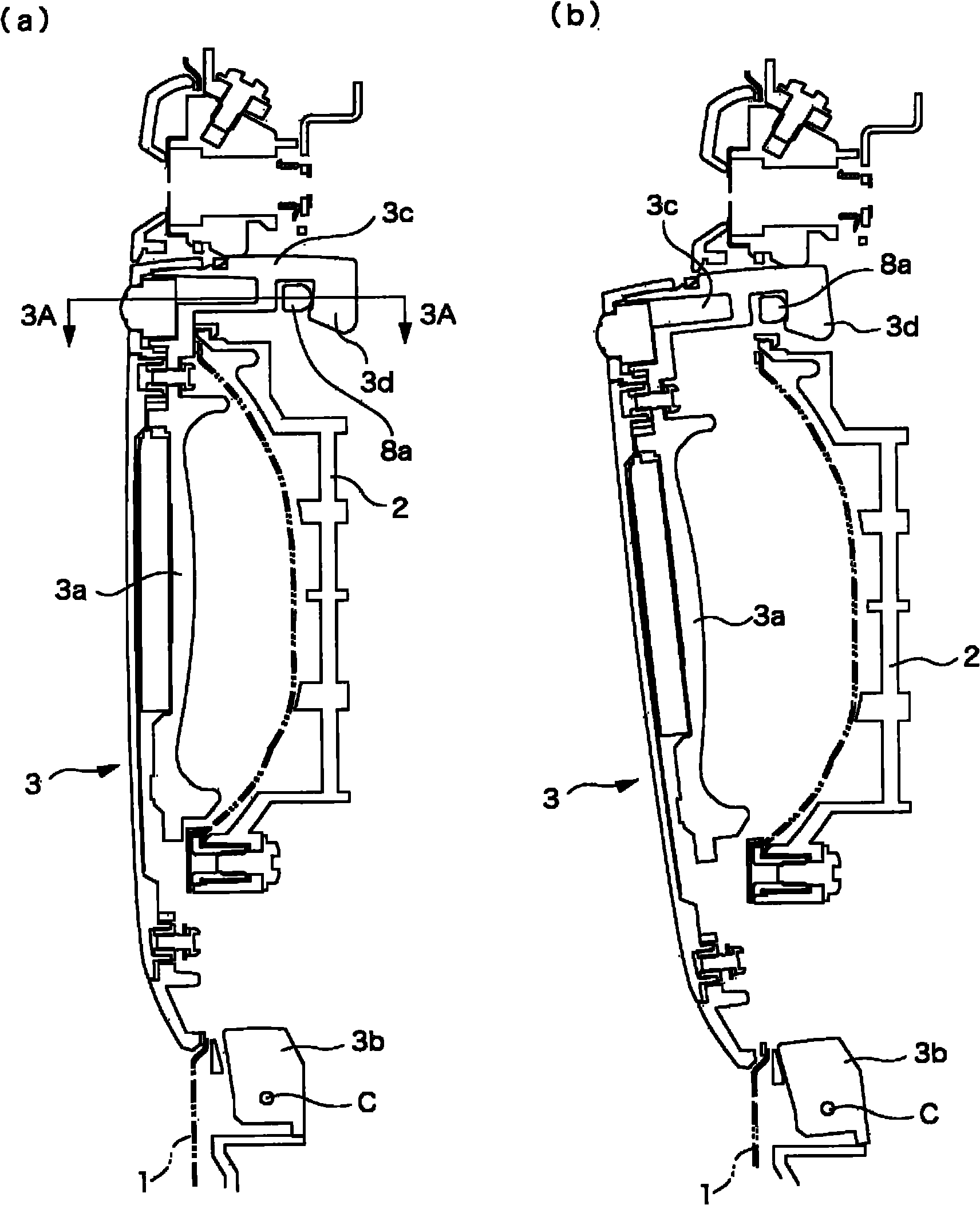

[0042] like figure 1 , etc., the handle device includes a handle base 2 fixed to a door 1 (door panel) of a vehicle, and an operation handle 3 rotatably coupled to the handle base 2 . The handle device of this embodiment is a so-called grip-type handle device, and is operated so as to hold the intermediate portion (the grip portion 3 a ) of the operation handle 3 and pull out. figure 1 Among them, the lower side is attached to the door 1 in a horizontal attitude toward the front direction of the vehicle.

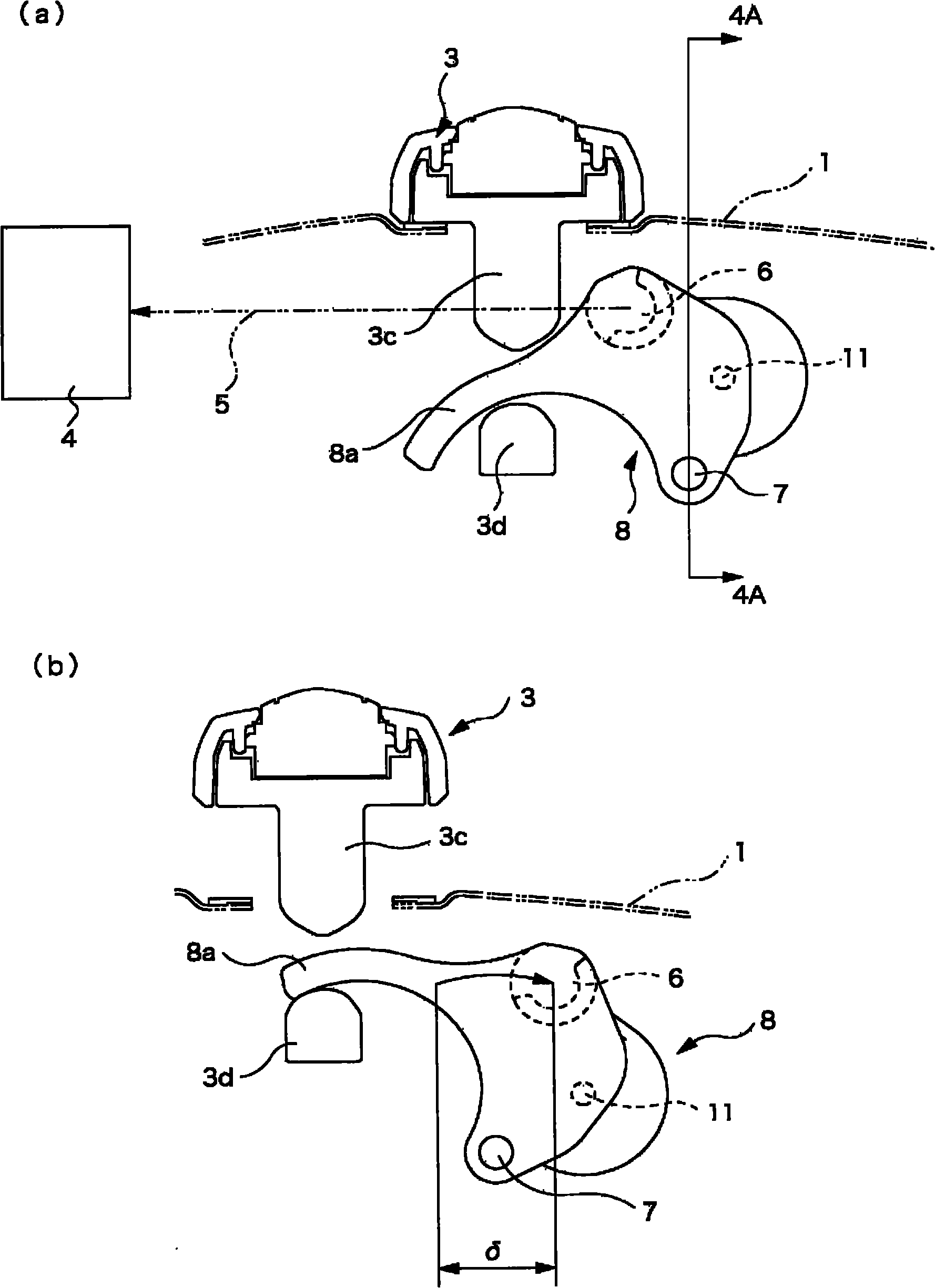

[0043] On the front end of the operating handle 3 (hereinafter, in this specification, the vehicle length direction is referred to as "front and rear", and the vehicle width direction is referred to as "front and back" based on the attitude of being mounted on the vehicle), such as figure 2 As shown in (a), the protruding hinge protrusion 3b is provided, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com