Flexible pipe assembly machine

A technology for assembly machines and hoses, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as high labor costs, hose leakage, and difficult product quality assurance, so as to improve work efficiency and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The hose assembly machine of the present invention will be described in further detail below in conjunction with the accompanying drawings.

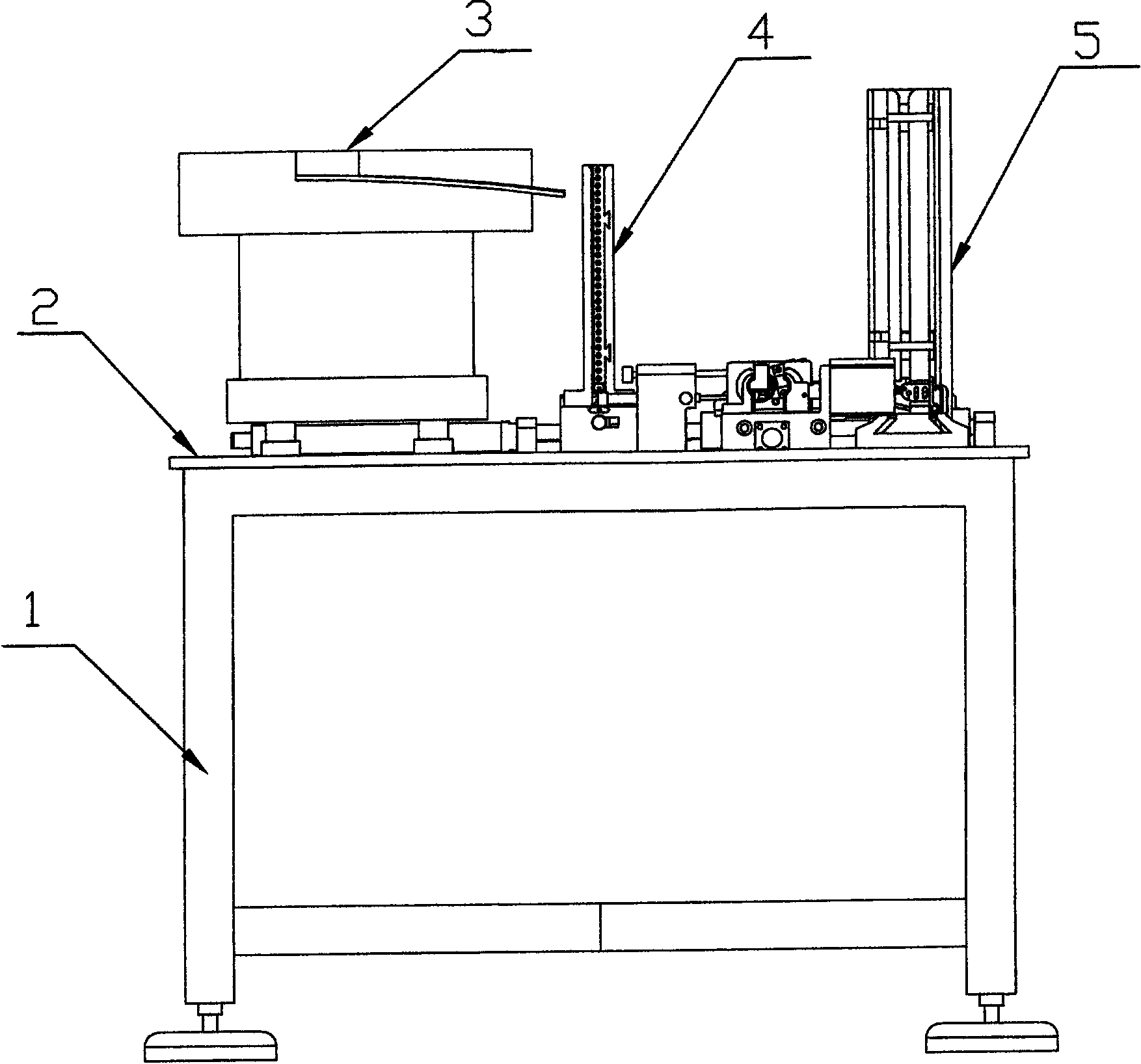

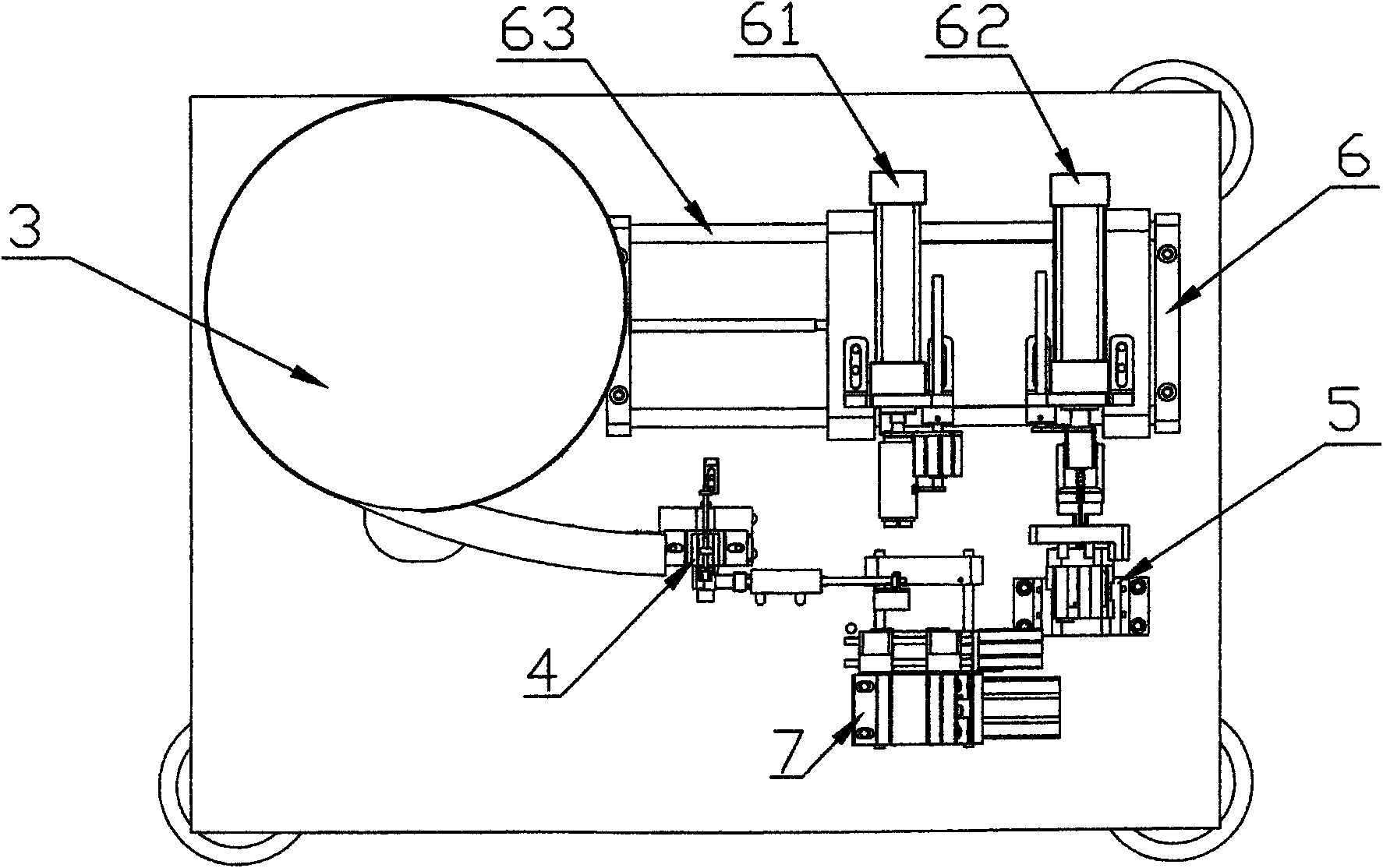

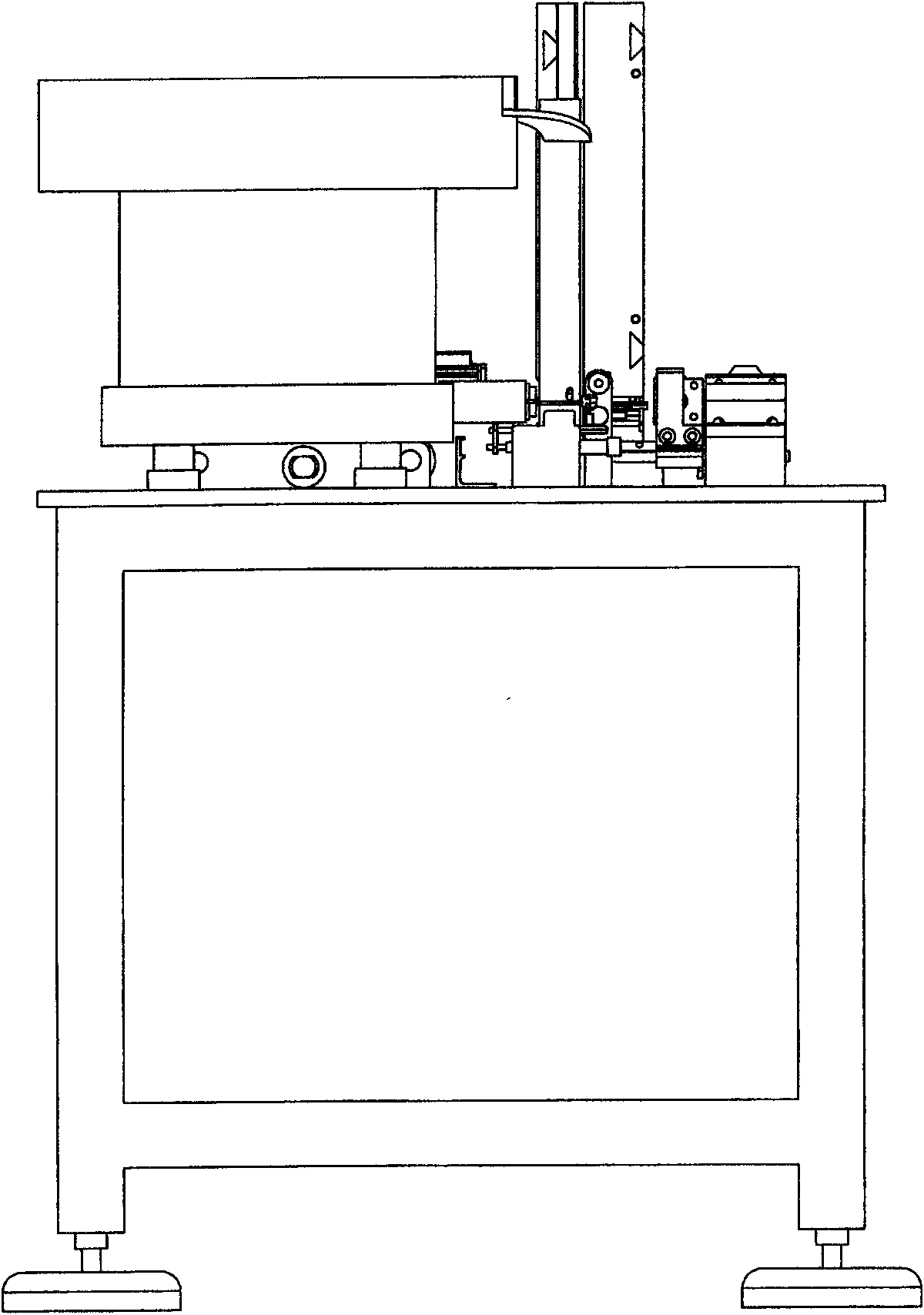

[0051] Figures 1A-1C It is a general assembly schematic diagram of the hose assembly machine of the present invention. As shown in the figure, the hose assembly machine of the present invention includes a vibrating feeder 3 installed on a workbench 2, a sleeve storage and supply device 4, a nut core storage and supply device 5, a sleeve core positioning and driving device 6 and Hose fixation shaping device 7. Wherein: the vibrating feeder 3 is an existing known device, and its discharge end is connected with the feed port of the cover storage and supply device, and is used to provide the cover stored therein to the cover storage and supply device 4 through vibration. Certainly, for the convenience of operation, the workbench 2 can be installed on the frame 1 .

[0052] Figures 2A-2C They are respectively a front view, a top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com