Method and device for detecting abrasion of cutting tool during work of numerical control machine

A technology of CNC machine tools and cutting tools, applied in manufacturing tools, metal processing equipment, measuring/indicating equipment, etc., can solve the problems of difficult judgment by operators, long time consumption, and prolonged production cycle, and improve pertinence and accuracy. , The effect of avoiding the processing size exceeding the standard and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

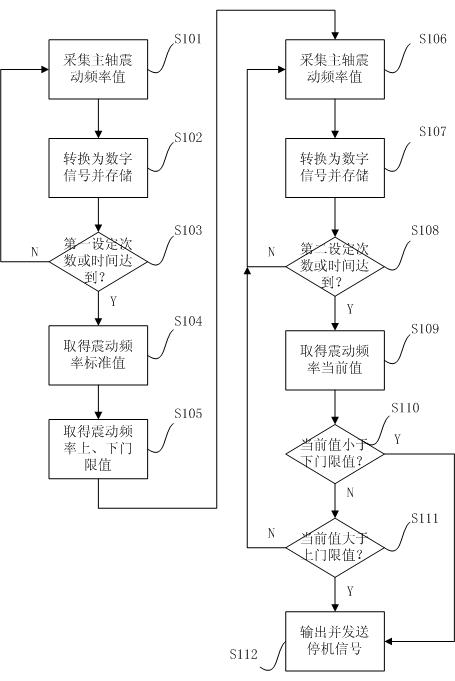

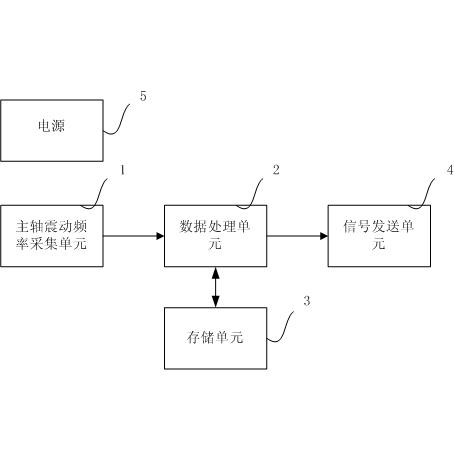

[0039] like figure 1 As shown, in the method and device embodiment of detecting cutting tool wear when the numerical control machine tool of the present invention is working, the method comprises the following steps:

[0040] Step S101 Collect the vibration frequency value of the spindle: Basically, when different CNC machine tools or the same CNC machine tool process workpieces of different materials or different feed speeds, the vibration frequencies of the spindle may be different. Therefore, it is unrealistic to set a standard value of spindle vibration for CNC machine tools in advance. Even if set, it may be inaccurate. In this embodiment, based on the above reasons, the method adopted is to sample the vibration frequency of the spindle for a certain period of time or a certain number of sampling times when the CNC machine tool is restarted to sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com