Chamfering device for hard and brittle plates

A technology of hard and brittle plates and chamfering devices, which is applied to the parts of grinding machine tools, the control of workpiece feed motion, and the machine tools suitable for grinding the edge of workpieces, etc. It can solve the problems of reducing productivity and obtaining the edge, etc. problem, to achieve the effect of high productivity and high precision chamfering processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, several preferred embodiments of the present invention will be described with reference to the drawings.

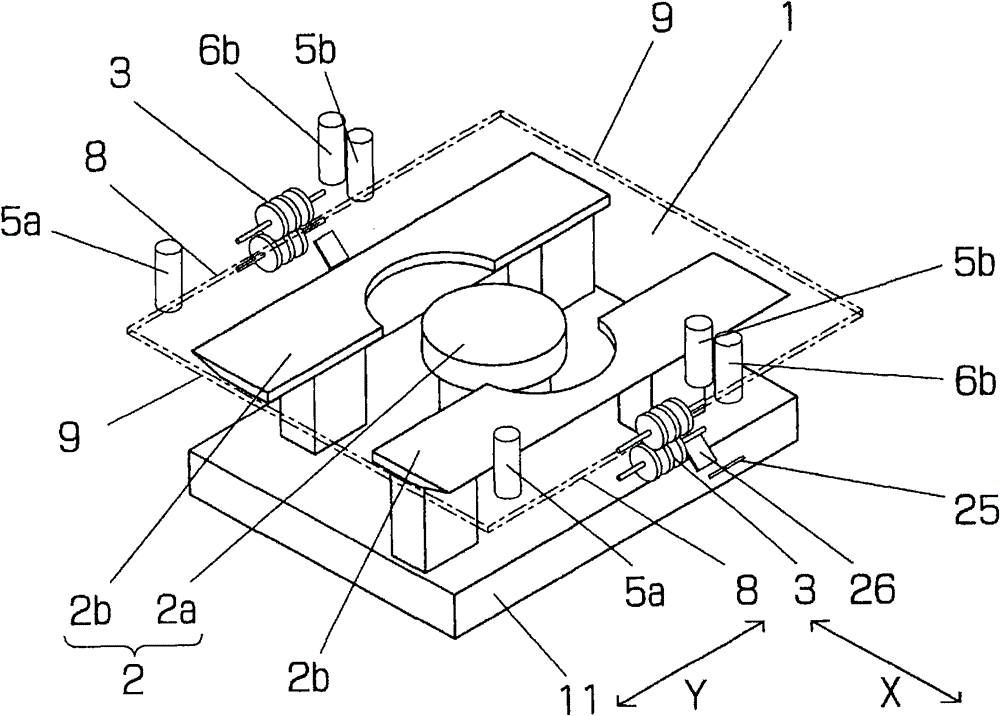

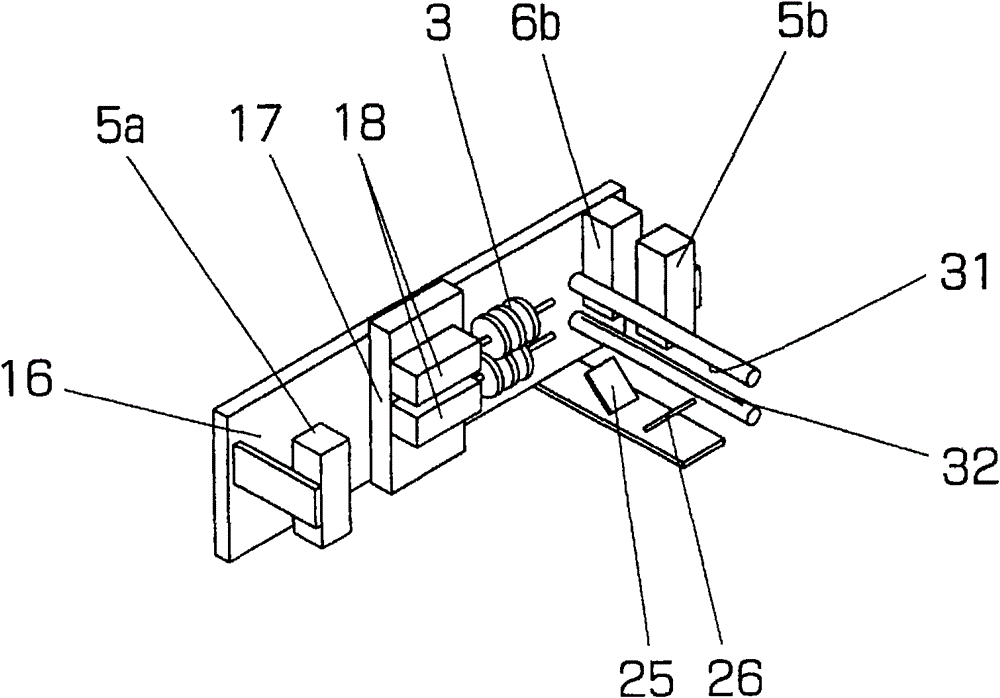

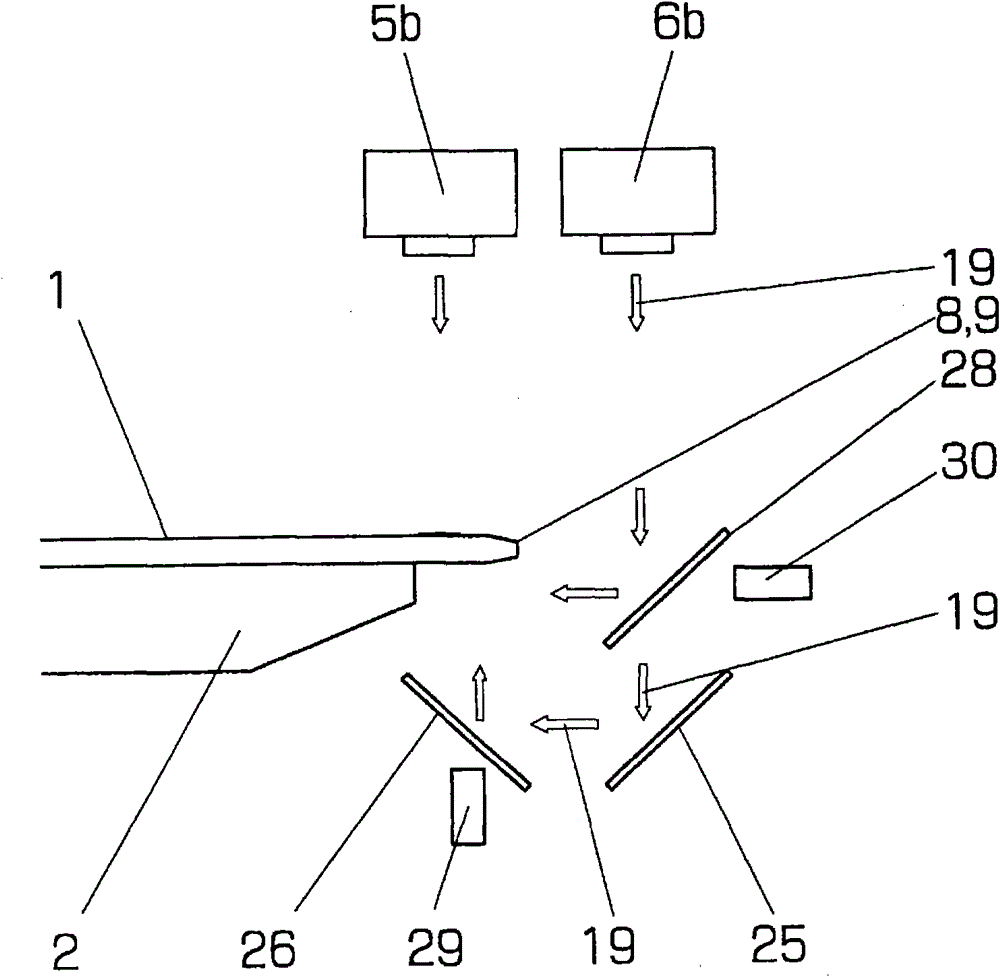

[0043] Figure 1 ~ Figure 3 It is a figure showing the first embodiment of the chamfering device of the present invention, figure 1 It is a perspective view showing the outline of the main machine structure, figure 2 is a schematic perspective view showing the installation structure of the tool and the camera, image 3 It is a front view showing the positional relationship between the downstream camera and the workpiece.

[0044] In the figure, 11 represents the workbench that moves along the guide rail in the y direction not shown, 2a represents the round table installed on the workbench 11 through the rotation device that is not shown in the figure and rotates around the vertical axis, and 2b represents the round table installed on the table The elongated side tables along the feed direction on both sides of the width direction (X direction in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com