Motor vehicle forward structure

A car body and front end technology, which is applied in the front end of the car body, can solve problems such as hindering cooling air and reducing cooling efficiency of coolers, and achieve the effects of improving mechanical stability, improving compatibility, and large degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

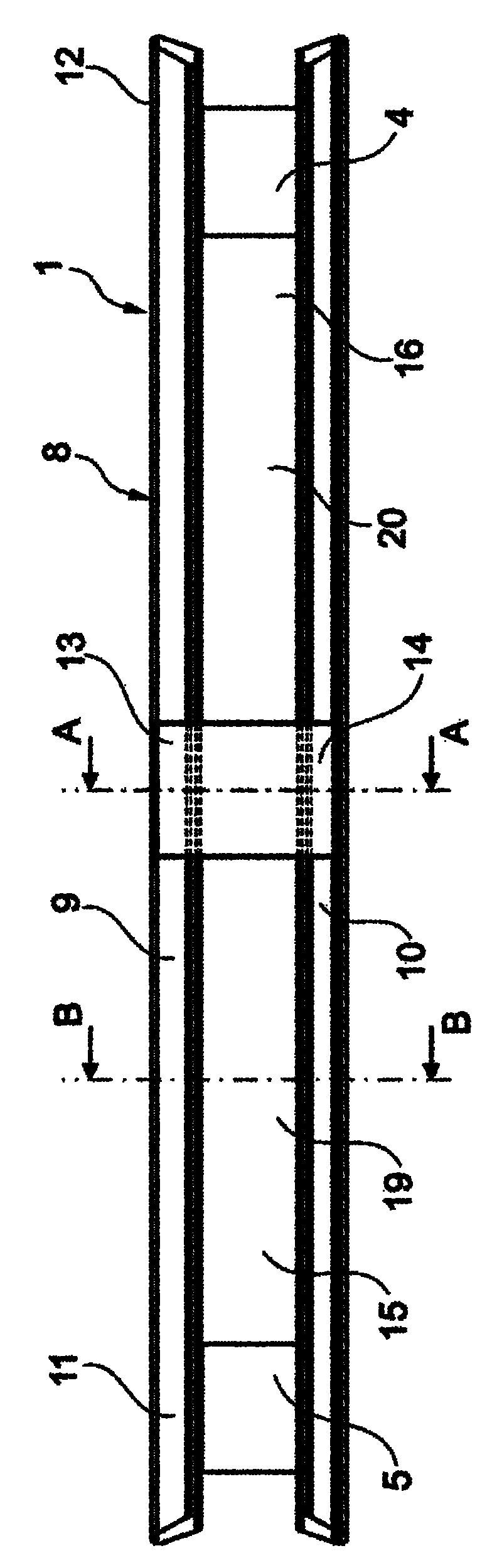

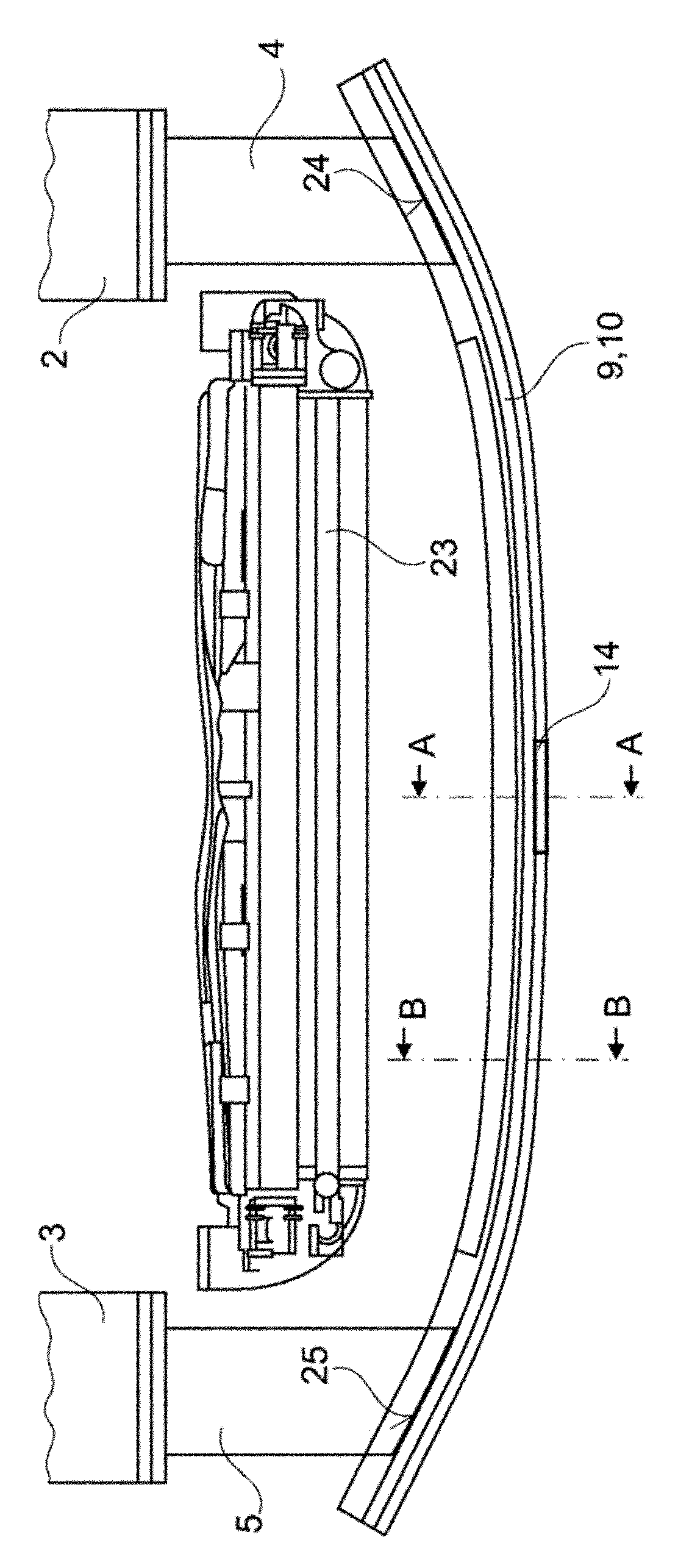

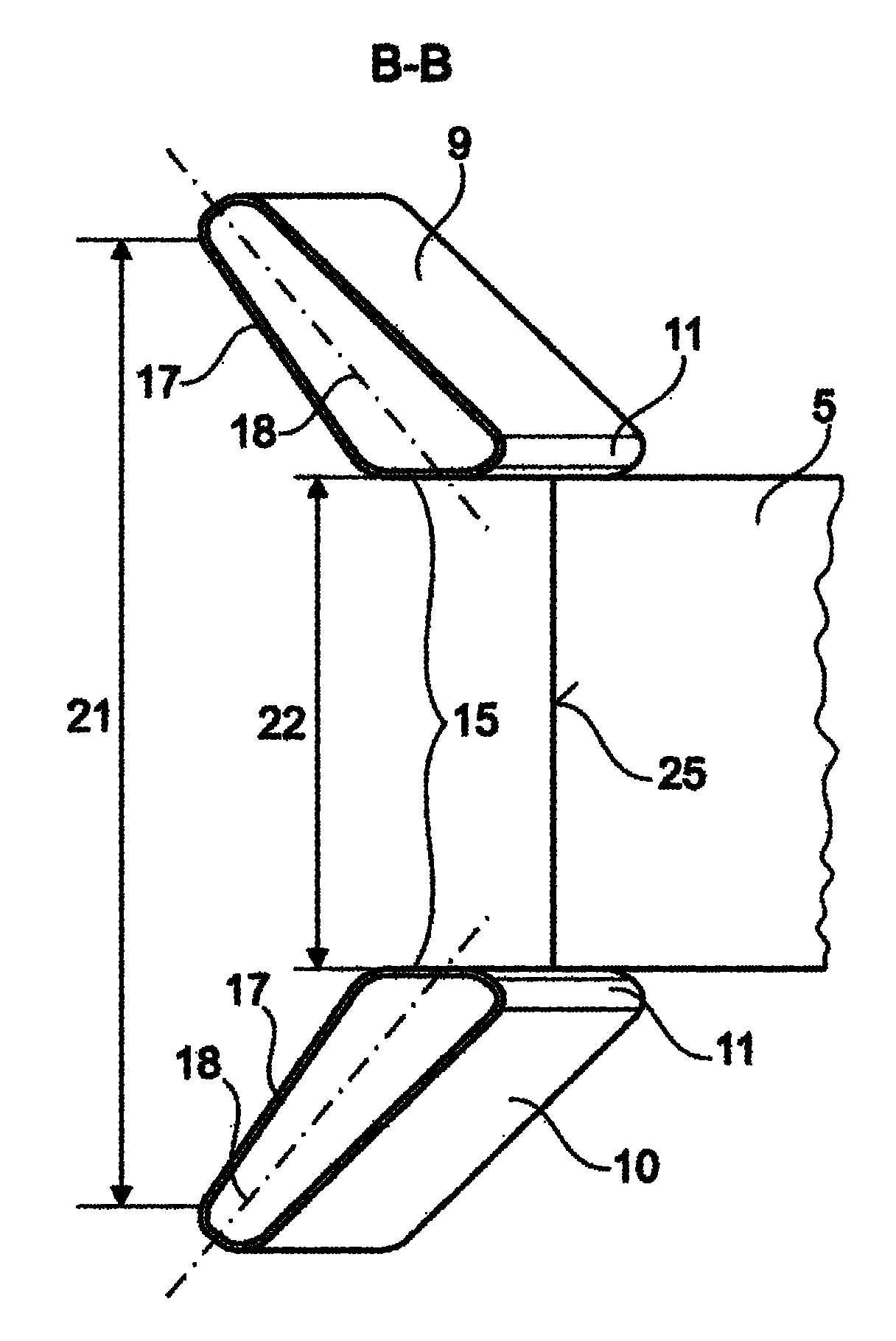

[0020] figure 1 A schematic front view of a motor vehicle front end 1 according to an embodiment of the invention is shown. For this reason, only so-called frontal crash structures for meeting crash and cooling requirements are shown for the motor vehicle front end 1 . All other front end components such as shock absorber diaphragms, cooling air louvers and other configurations are omitted here. figure 1 The schematic front view shown in , only shows the cross member structure 8 designed as a crash structure or bumper structure. Contrary to the previously shown prior art, the cross member structure 8 consists of a first upper bumper cross member 9 and a second lower bumper cross member 10 , which are fastened in their end regions 11 and 12 respectively in the crash zone. box of 4 or 5 on. Such fixing may include welding, brazing or bolting. The crash box itself has a flexible material that deforms and attenuates the crash energy when subjected to a crash or impact energy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com