Low-temperature quick sintered high-strength aluminum oxide ceramic and preparation method thereof

A high-speed technology for alumina ceramics, which is applied in the field of low-temperature rapid firing high-strength alumina ceramics and its preparation, can solve the problems of poor mechanical properties, high cost, and unsuitability for industrial scale production, and achieve improved sintering performance and mechanical properties. The effect of solving the abnormal growth of grains and inhibiting the abnormal growth of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

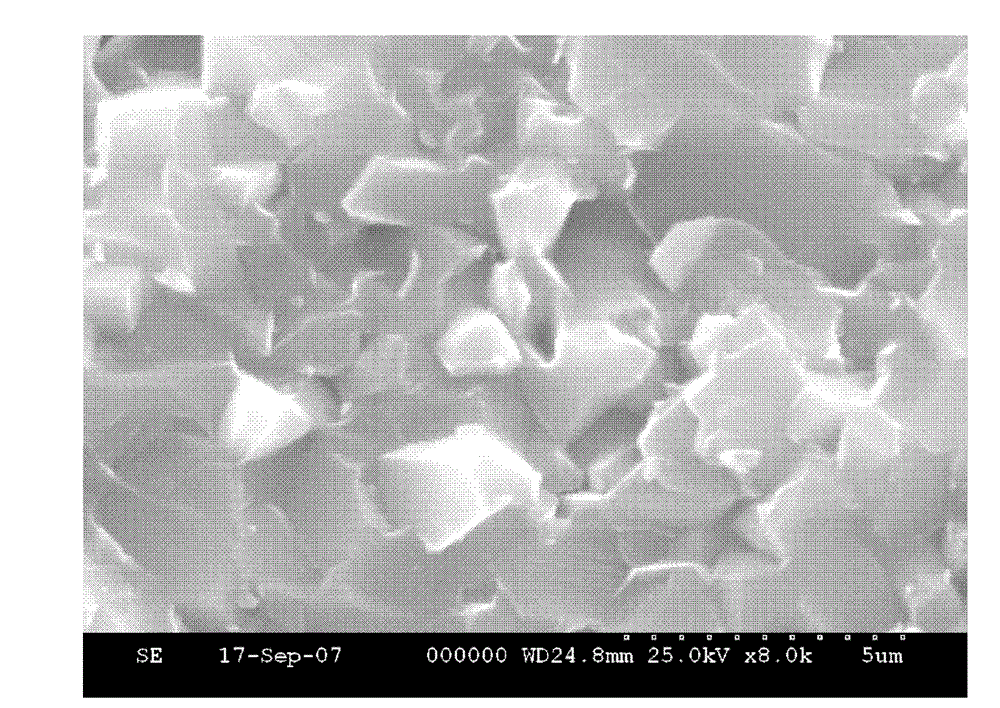

Image

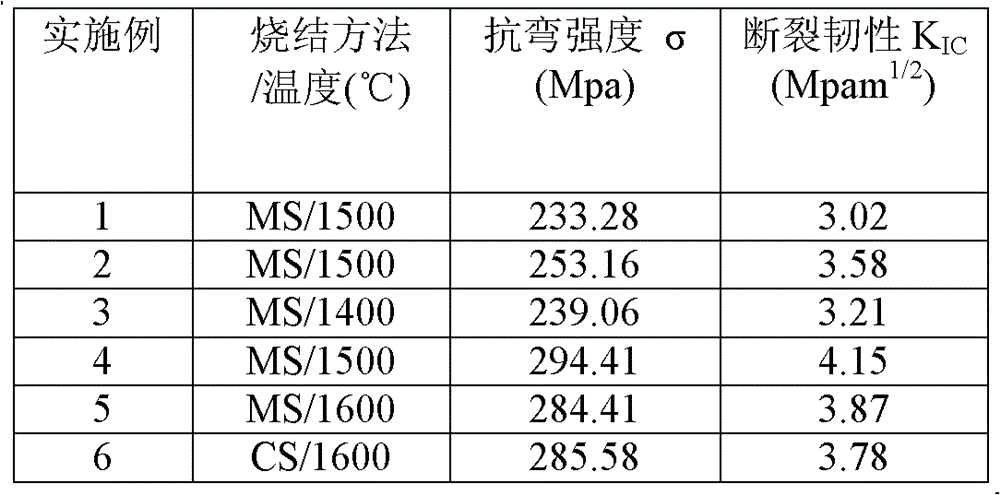

Examples

Embodiment 1

[0025] No nano-Al is added in this embodiment 2 o 3 powder to prepare alumina ceramics for comparison.

[0026] In this embodiment, the raw materials of high-strength alumina ceramics fired rapidly at low temperature are composed of:

[0027] Coarse crystalline Al 2 o 3 Powder 100g;

[0028] Sintering aid: SiO 2 Powder 1.6g, talcum powder 2g, limestone powder 0.4g;

[0029] Of which coarse-grained Al 2 o 3 Powder median diameter D 50 Particle size is 0.6-1.0μm, nano Al 2 o 3 The particle size of the powder is 10-30nm.

[0030] In this embodiment, low-temperature rapid firing high-strength alumina ceramics are prepared according to the following steps:

[0031] a. Abrasive

[0032] Coarse crystalline Al 2 o 3 Powder, SiO 2 Powder, talc powder and limestone powder are mixed to obtain a mixture, and the mixture is put into a planetary ball mill, using a polytetrafluoroethylene ball mill jar, the grinding medium is zirconia balls, and absolute ethanol is used as a ...

Embodiment 2

[0039] In this embodiment, the raw materials of high-strength alumina ceramics fired rapidly at low temperature are composed of:

[0040] Coarse crystalline Al 2 o 3 Powder 60g; Nano Al 2 o 3 Powder 40g;

[0041] Sintering aid: SiO 2 Powder 1.35g, talcum powder 1.35g, limestone powder 0.3g;

[0042] Of which coarse-grained Al 2 o 3 Powder median diameter D 50 Particle size is 0.6-1.0μm, nano Al 2 o 3 The particle size of the powder is 10-30nm.

[0043] In this embodiment, low-temperature rapid firing high-strength alumina ceramics are prepared according to the following steps:

[0044] a. Abrasive

[0045] Coarse crystalline Al 2 o 3 powder, nano Al 2 o 3 Powder, SiO 2 Powder, talc and limestone powder are mixed to obtain a mixture, and the mixture is put into a planetary ball mill, using a polytetrafluoroethylene ball mill jar, the grinding medium is zirconia balls, and absolute ethanol is used as a solvent, wet ball milled for 5 hours, and the ball mill is o...

Embodiment 3

[0052] In this embodiment, the raw materials of high-strength alumina ceramics fired rapidly at low temperature are composed of:

[0053] Coarse crystalline Al 2 o 3 Powder 70g; Nano Al 2 o 3 Powder 30g;

[0054] Sintering aid: SiO 2 powder 2.4g, talcum powder 3g, limestone powder 0.6g;

[0055] Of which coarse-grained Al 2 o 3 Powder median diameter D 50 Particle size is 0.6-1.0μm, nano Al 2 o 3 The particle size of the powder is 10-30nm.

[0056] In this embodiment, low-temperature rapid firing high-strength alumina ceramics are prepared according to the following steps:

[0057] a. Abrasive

[0058] Coarse crystalline Al 2 o 3 powder, nano Al 2 o 3 Powder, SiO 2 Powder, talc and limestone powder are mixed to obtain a mixture, and the mixture is put into a planetary ball mill, using a polytetrafluoroethylene ball mill jar, the grinding medium is zirconia balls, and absolute ethanol is used as a solvent, wet ball milled for 8 hours, and the ball mill is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com