Method for increasing air tightness of coke oven top and oven top structure

A furnace top gas and furnace roof technology is applied in the directions of preventing expansion/contraction of coke ovens, preventing/repairing the leakage of bricks, etc., which can solve problems such as damage and achieve the effect of preventing mutual leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

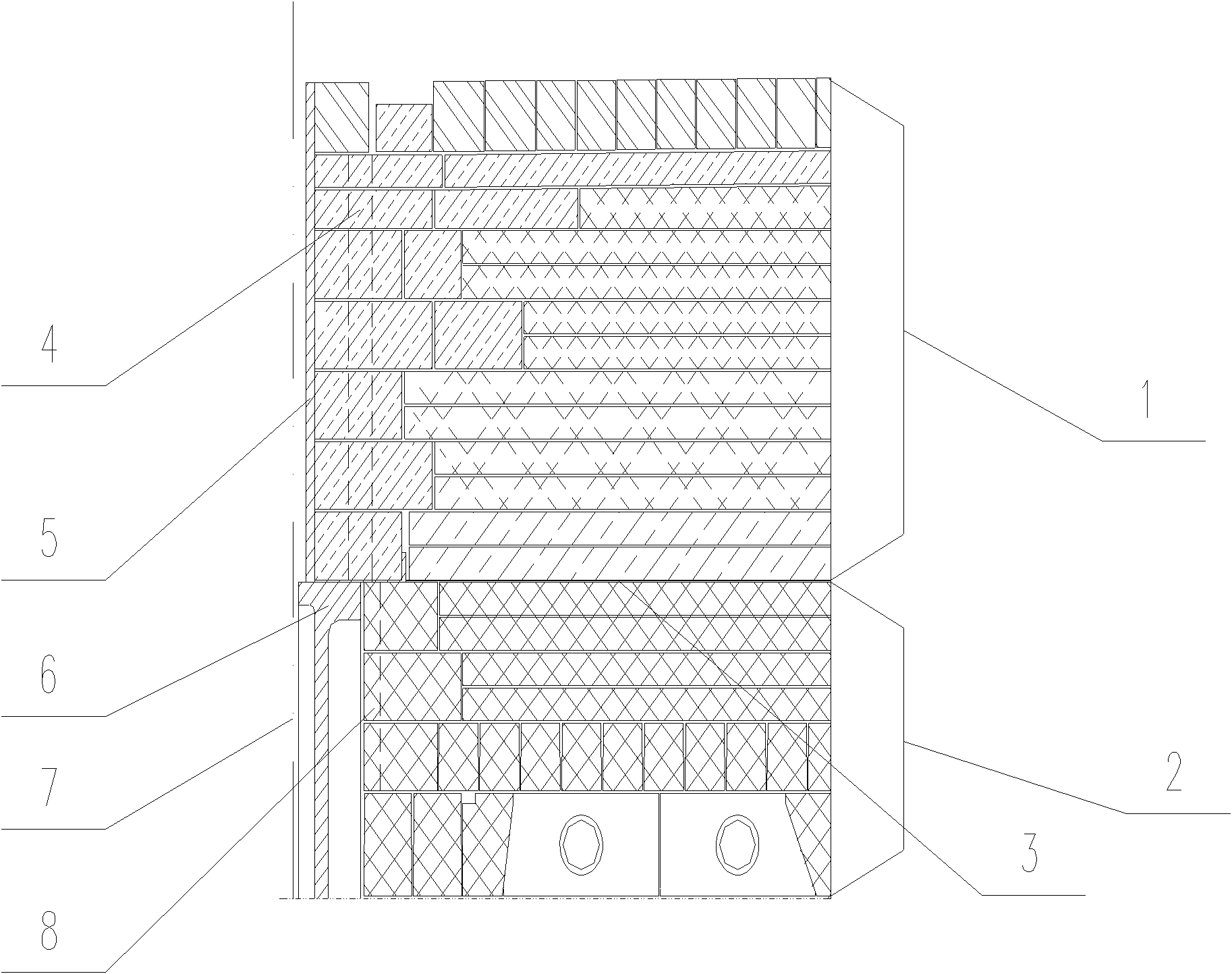

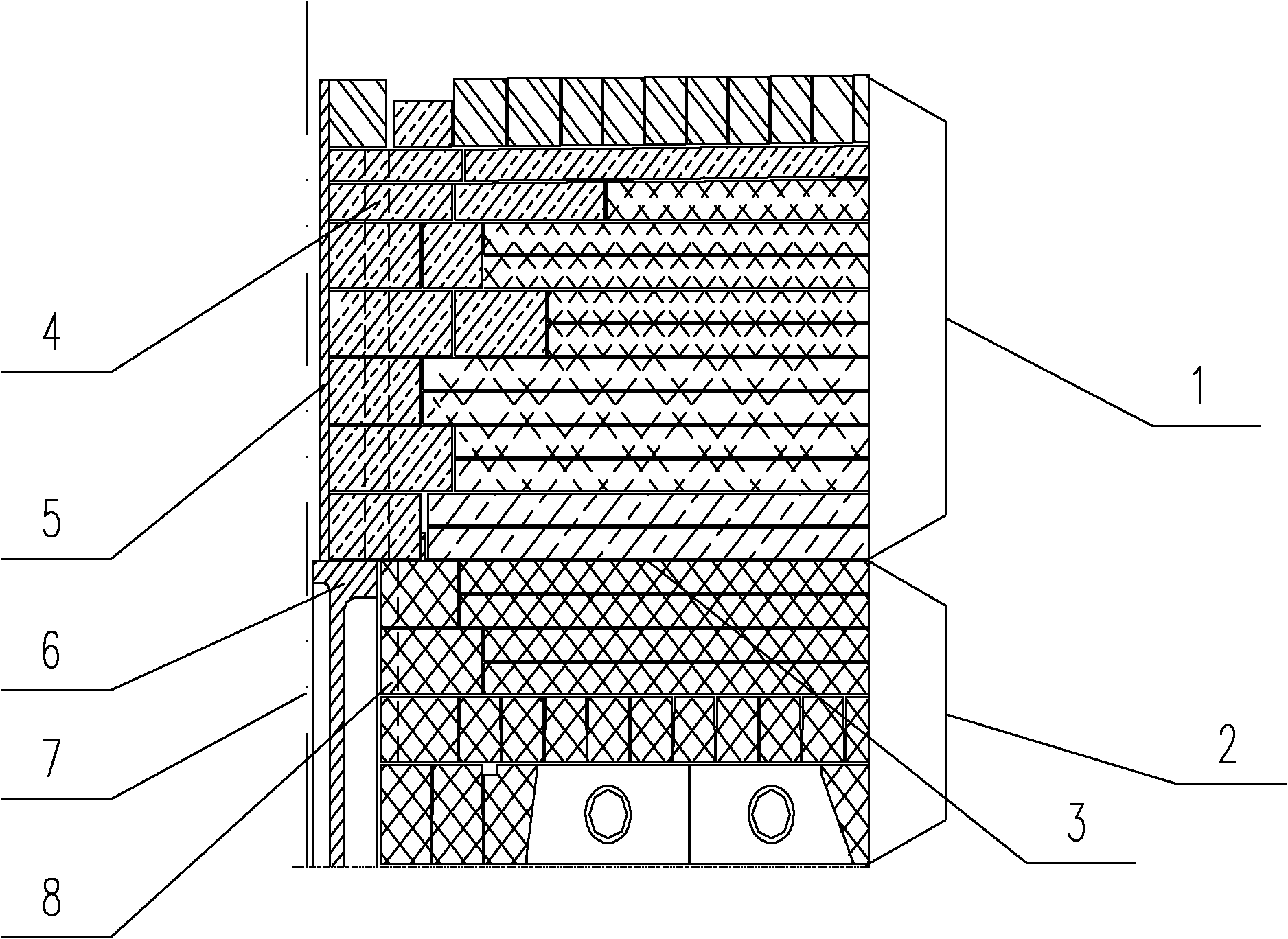

[0015] See figure 1 , a coke oven roof structure, the coke oven roof is divided into two parts: the upper part of the furnace roof 1 and the lower part of the furnace roof 2, the upper part of the furnace roof is built with clay bricks, and the lower part of the furnace roof is built with silica bricks. The upper part 1 of the furnace roof and the lower part 2 of the furnace roof are respectively built as an independent whole, and there is no brick groove tongue between the upper part 1 of the furnace roof and the lower part 2 of the furnace roof, and a sliding layer 3 is provided; the sliding layer 3 can be a graphite layer, Slide the grease layer, etc. At the burner head position, a grouting hole 4 is provided on the upper part of the furnace roof 1 , and the upper part of the furnace roof is close to the burner head protection device 5 . A la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com