Rear beam driving mechanism of jet loom

A back beam drive mechanism, air-jet loom technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of air-jet looms, severe vibration of the back beam, etc., and achieve the effect of reducing the breakage rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

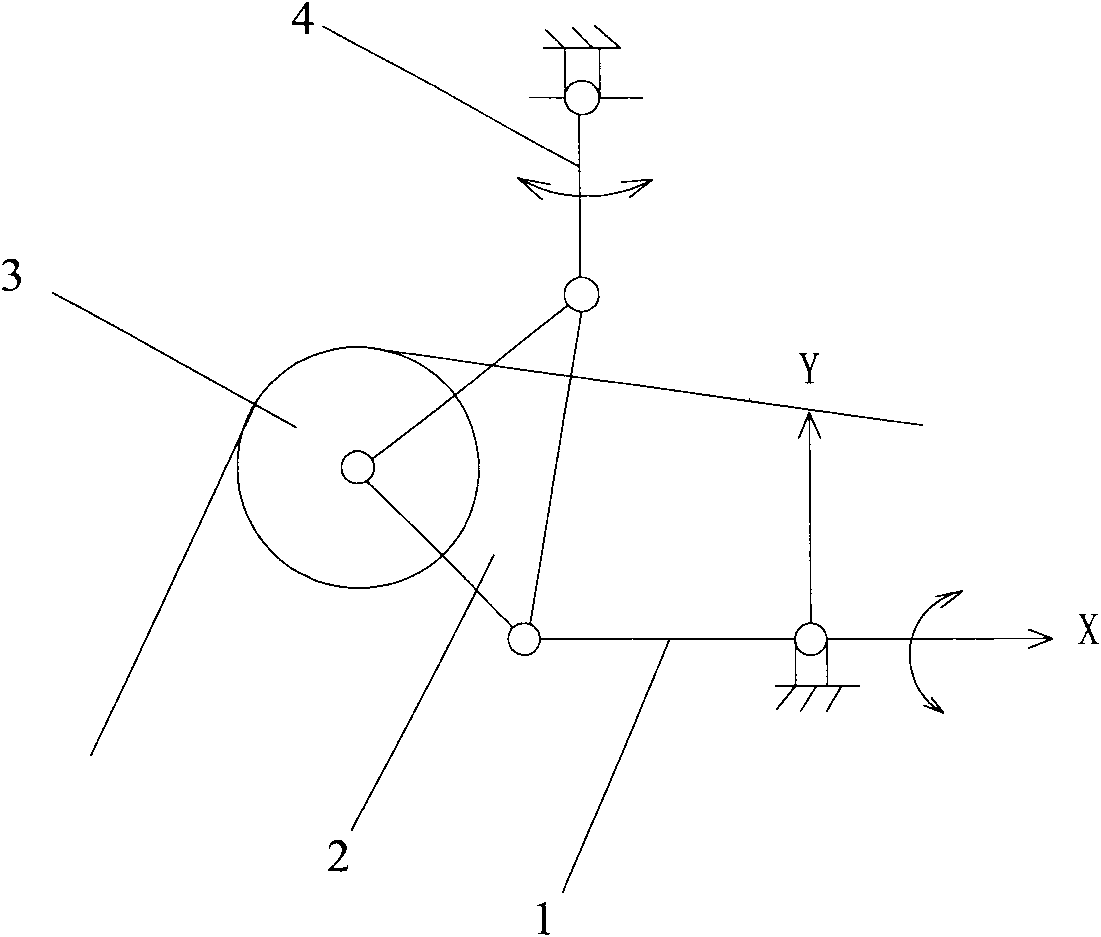

[0014] figure 1 Shown is the back rest driving mechanism in the prior art, which is a double rocker mechanism. All the warp yarns bypass the surface of the back rest 3. During the high-speed weaving process, the back rest vibrates greatly and the force on the rods is large, which increases the load on the warp yarns. As the warp tension increases, the rate of warp yarn breakage increases significantly, and if the warp yarn breakage is too frequent, the superiority of the high-speed loom will be offset.

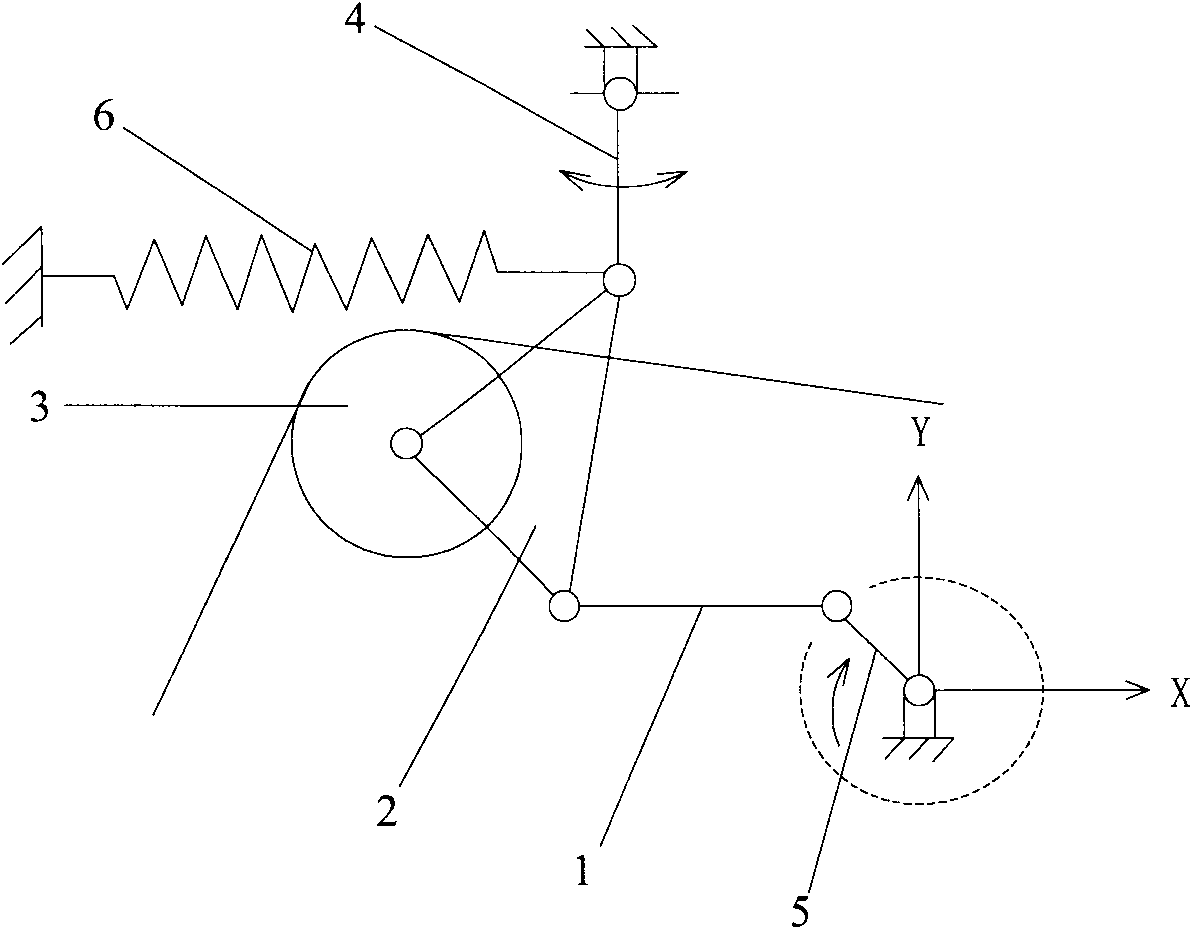

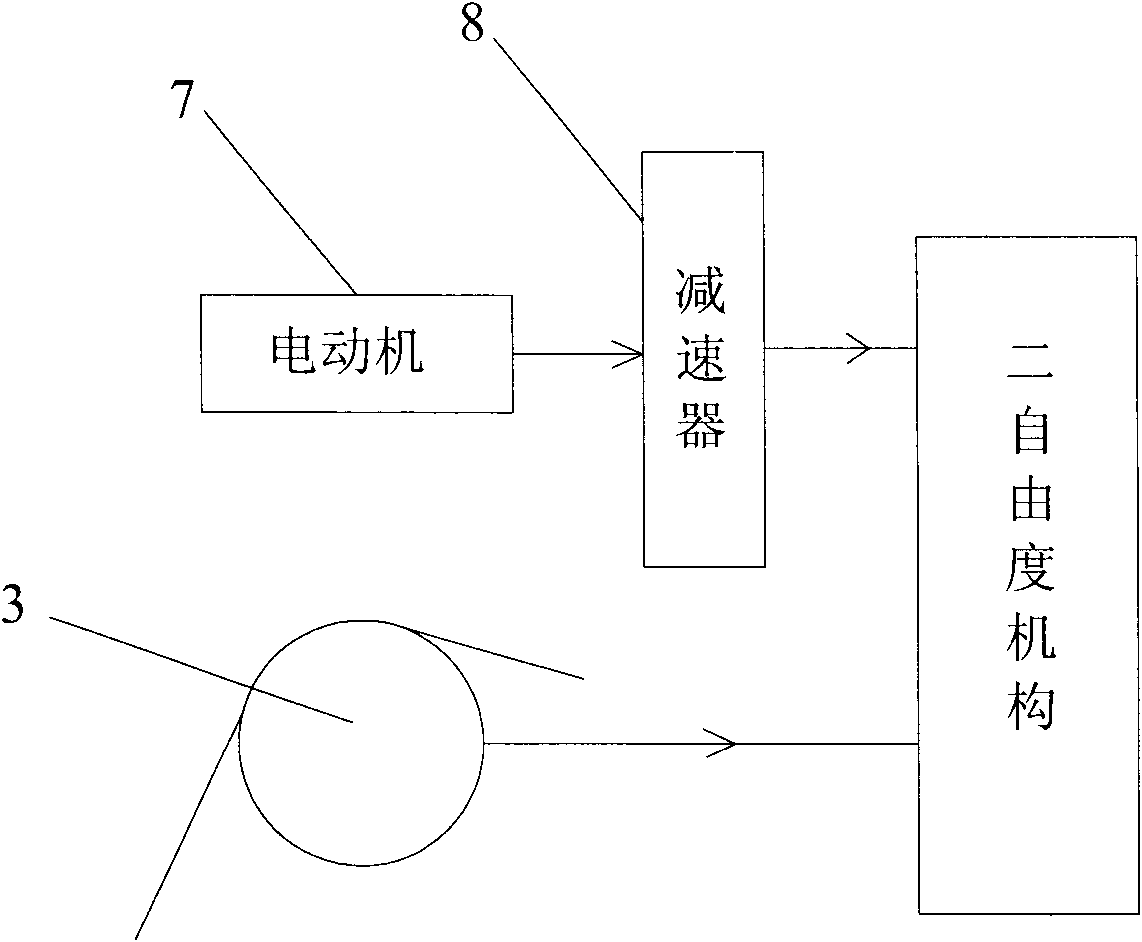

[0015] refer to figure 2 , the back beam driving mechanism of the air-jet loom of the present invention is a kind of five-bar mechanism, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com