Thermosistor seat assembly of engine cooling system

An engine cooling and thermostat technology, which is used in engine cooling, engine components, machines/engines, etc., can solve the problems of complex peripheral pipeline layout, large internal resistance of the cooling system, and many assembly processes, so as to avoid the risk of water leakage. , saving and clamp connection structure, the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

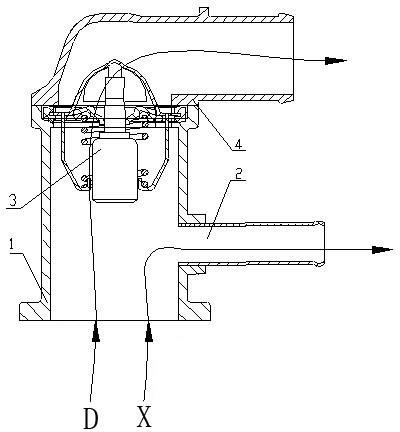

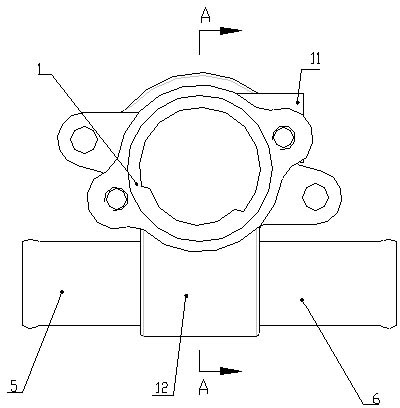

[0016] Below in conjunction with accompanying drawing, structure and working method of the present invention are described in detail:

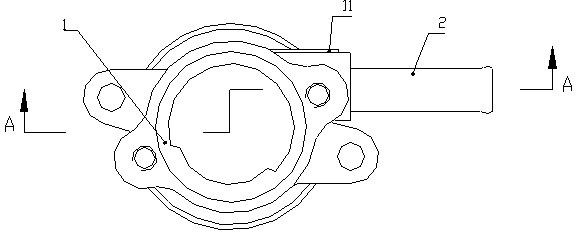

[0017] The structure of the thermostat seat assembly of the present invention is as follows: image 3 Shown: including the thermostat seat 1, the thermostat seat 1 is a cavity structure connected at both ends, one end of the cavity is connected to the coolant outlet of the engine cylinder head, and the other end of the cavity is used to install the regulator Thermostat assembly. A water inlet pipe cavity 12 is integrally formed on the side wall 14 of the end connected to the coolant outlet position of the thermostat seat 1 near the engine cylinder head, and a water temperature sensor mounting hole 11 is processed on the thermostat seat 1 for further The water pipe cavity 12 is also a cavity structure with both ends connected. The radiator outlet connecting pipe 5 and the water pump inlet pipe 6 are assembled at both ends of the water inlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com