Blade structure of wind wheel for vertical shaft wind-driven generator

A technology of blade structure and vertical axis, applied in the field of blade structure of vertical axis wind turbine wind turbine, can solve the problem that the wind rotor has not been completely solved, and achieve the effect of light weight, simple combined processing and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

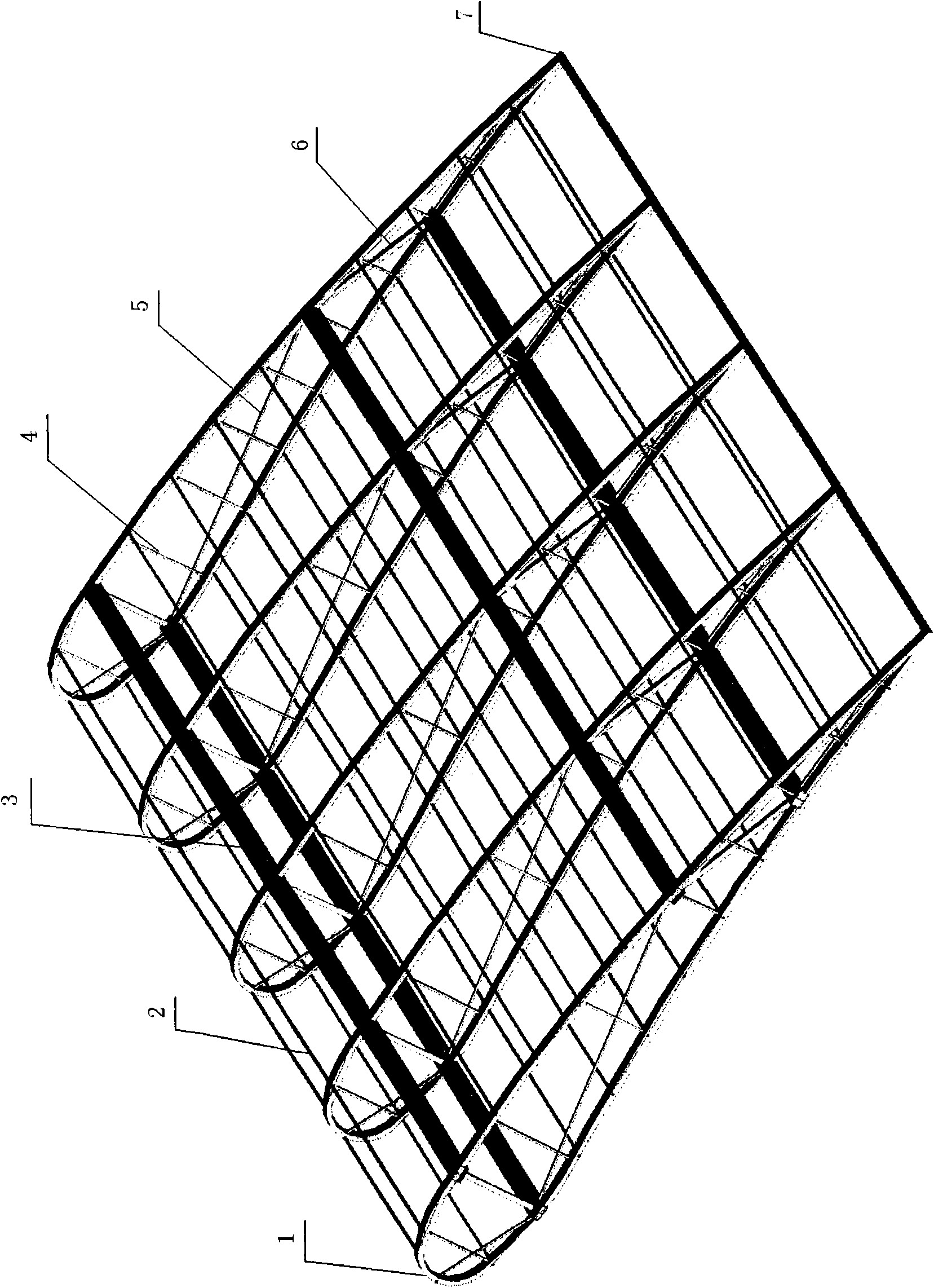

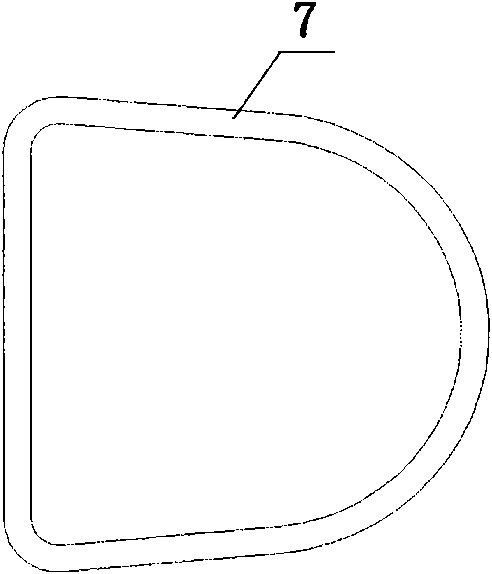

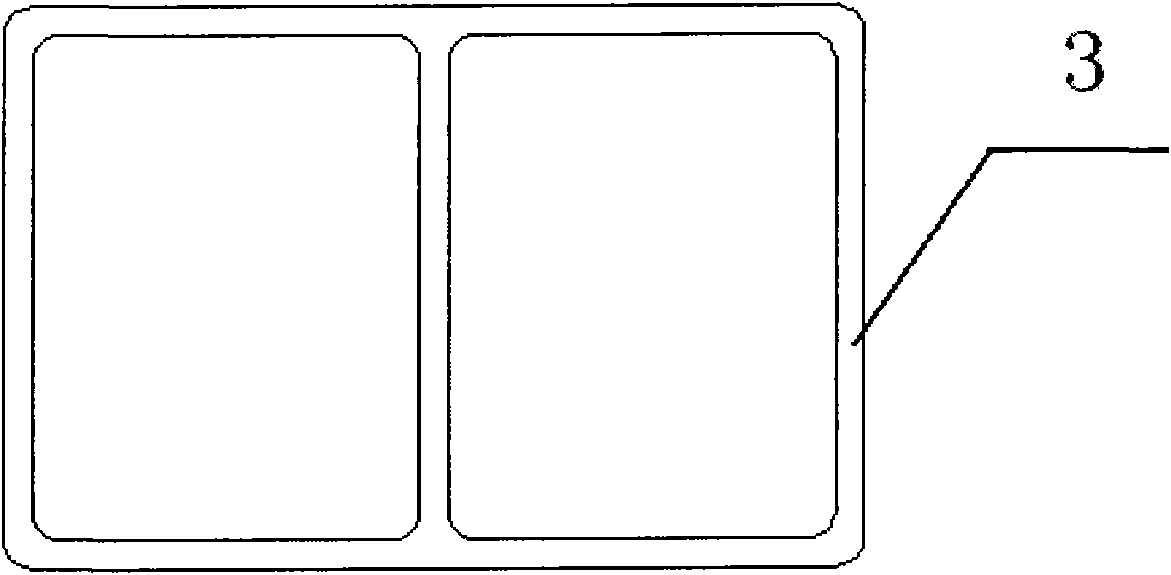

[0033] Such as figure 1 As shown, the blade of the vertical axis wind turbine rotor provided by the present invention includes a skeleton forming the shape of the blade and a skin (not shown) fixed outside the skeleton, and the shape of the blade is a vertical columnar body , its horizontal section is the cross-sectional shape of the aircraft wing, that is, relative to the rotation axis 03 of the wind rotor (see Figure 6 , 7 ), the outer surface of the blade 01 facing outward is a streamlined arc surface, and the smooth transition between the outer surface and the opposite inner surface forms a larger windward end, that is, the head of the blade and a smaller tail.

[0034] Relative to the vertical axis of the wind rotor shaft 03, the distance between the outer surface and the inner surface of the cylinder basically gradually decreases from the head to the tail; in the vertical direction of the blade, each horizontal The cross-sectional size and shape are the same.

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com