Floating type servo valve

By adopting a floating design and a displacement amplification mechanism in the servo valve, the problems of limited output flow and high friction of the existing servo valve are solved, high sensitivity and dynamic and static performance are improved, and it can adapt to the needs of different equipment interfaces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

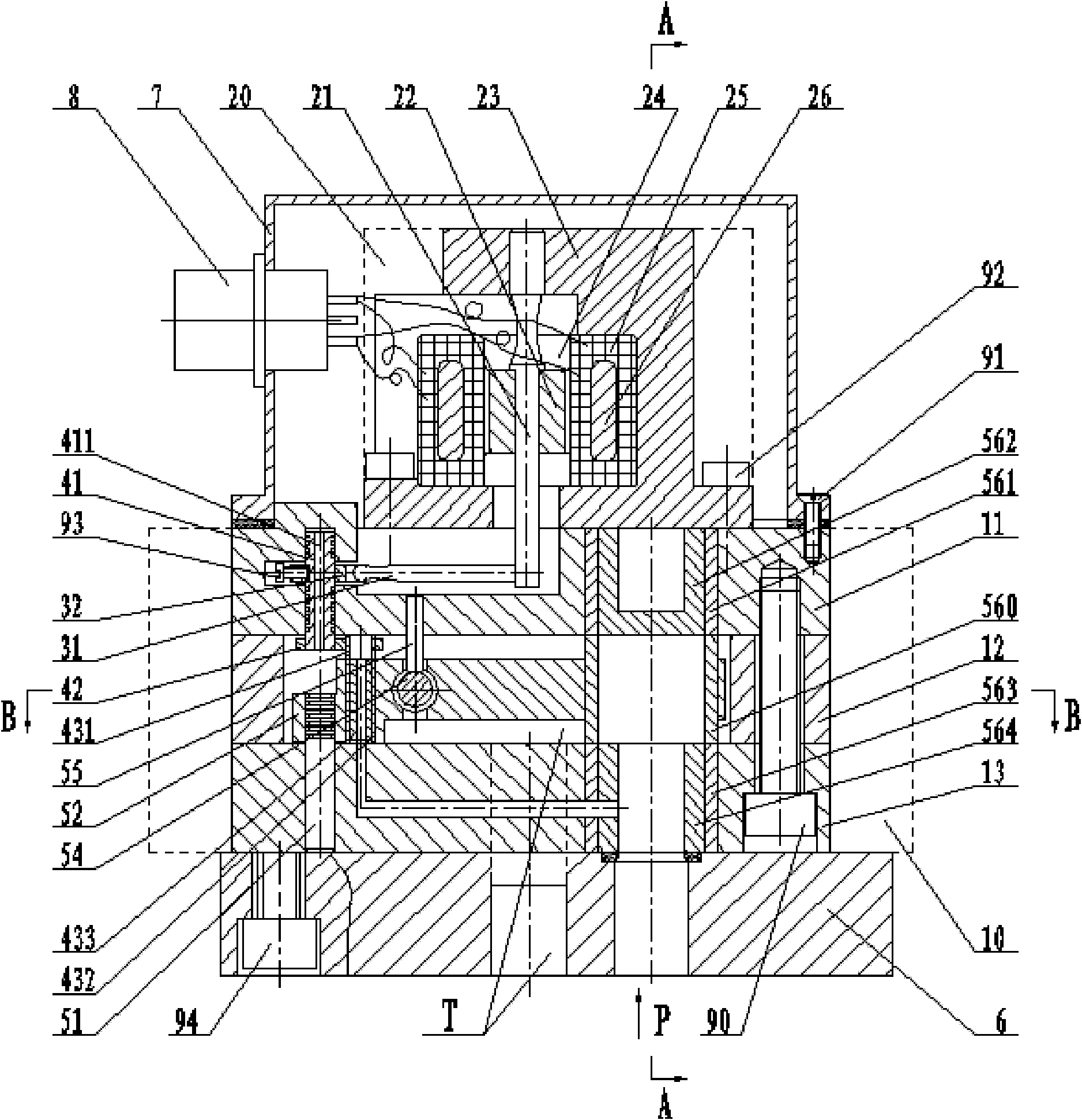

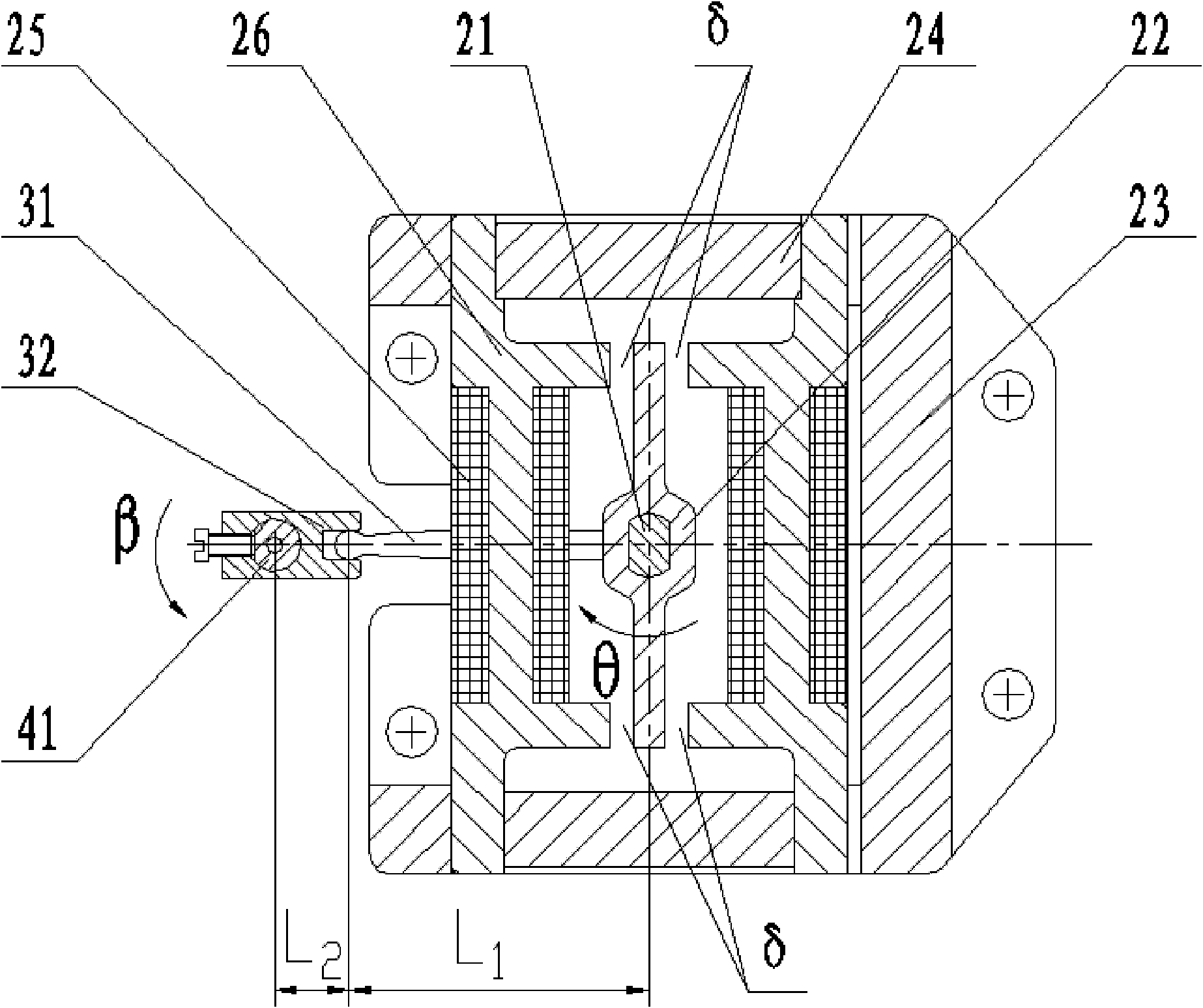

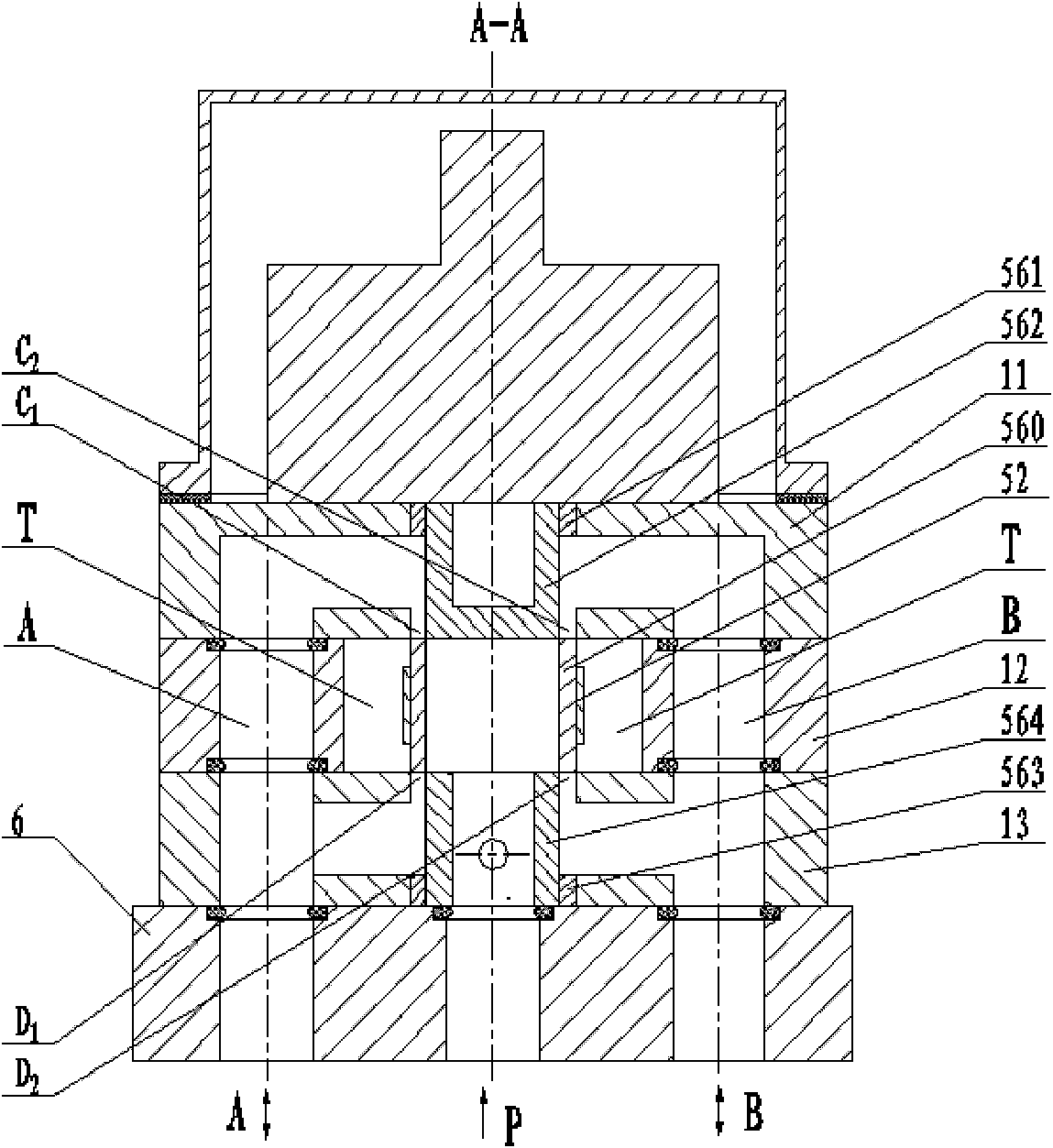

[0036] Such as Figure 1 to Figure 7 As shown, the floating servo valve of the present invention is mainly composed of a valve body 10, a torque motor 20, a pilot stage control mechanism and a power stage control mechanism arranged in the inner cavity of the valve body.

[0037] The valve body 10 includes an upper valve block 11 , a middle partition 12 and a lower valve block 13 , which are stacked in sequence and fastened by screws 90 . The upper and lower planes of the middle partition 12 are parallel to each other, and the middle partition 12 is provided with two flow holes A and B, and the upper valve block 11 and the lower valve block 13 are respectively provided with flow holes corresponding to the flow holes A and B. The holes are arranged in the corresponding orifices of the three to communicate with each other respectively. The outer co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com