Equipment for processing tooth surface of gear

A processing equipment and tooth surface technology, which is applied in the field of gear tooth surface processing equipment, can solve the problems that the diameter of the tooth surface of the gear cannot be guaranteed to be consistent, the stability of the large and small columns is different, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

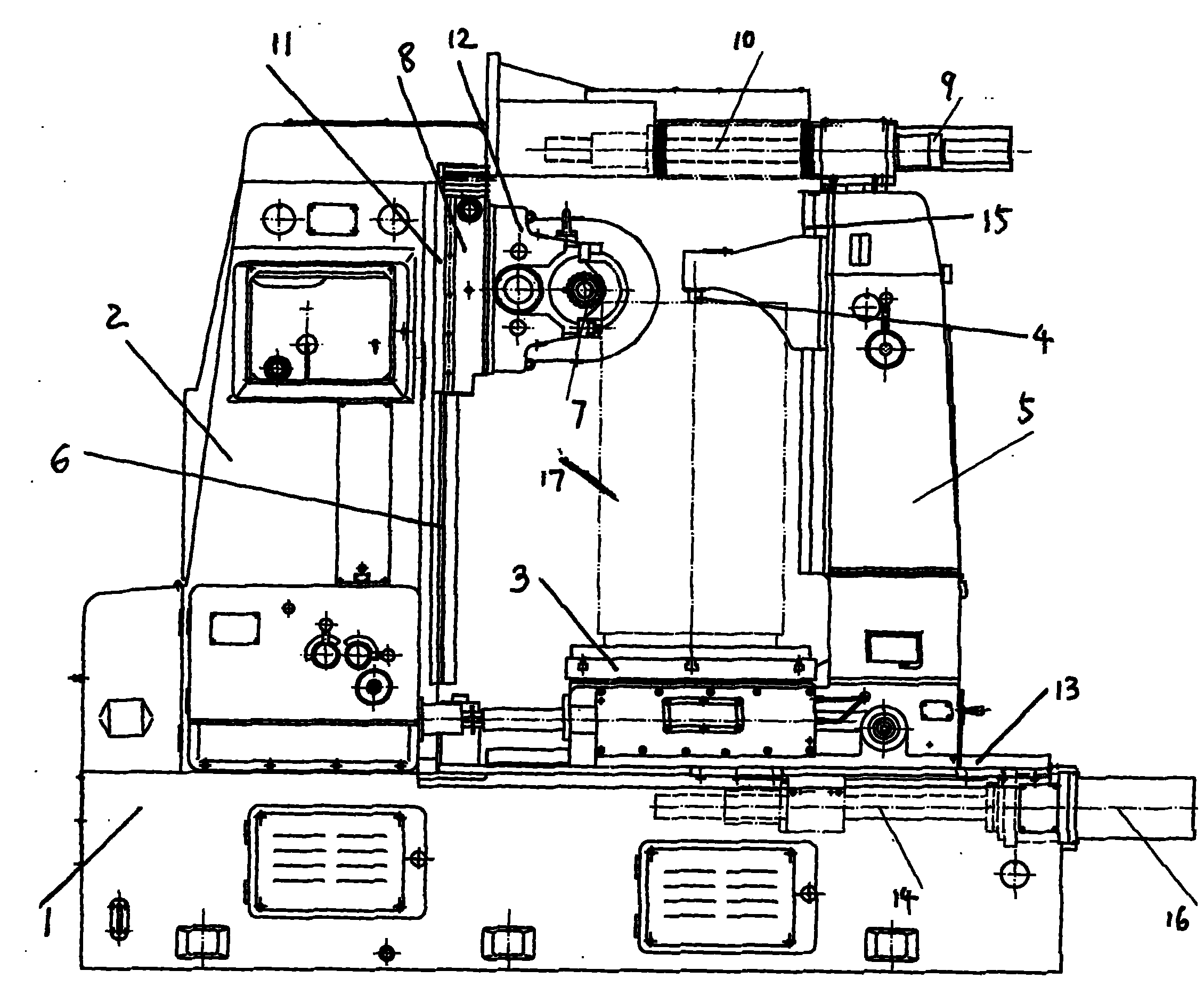

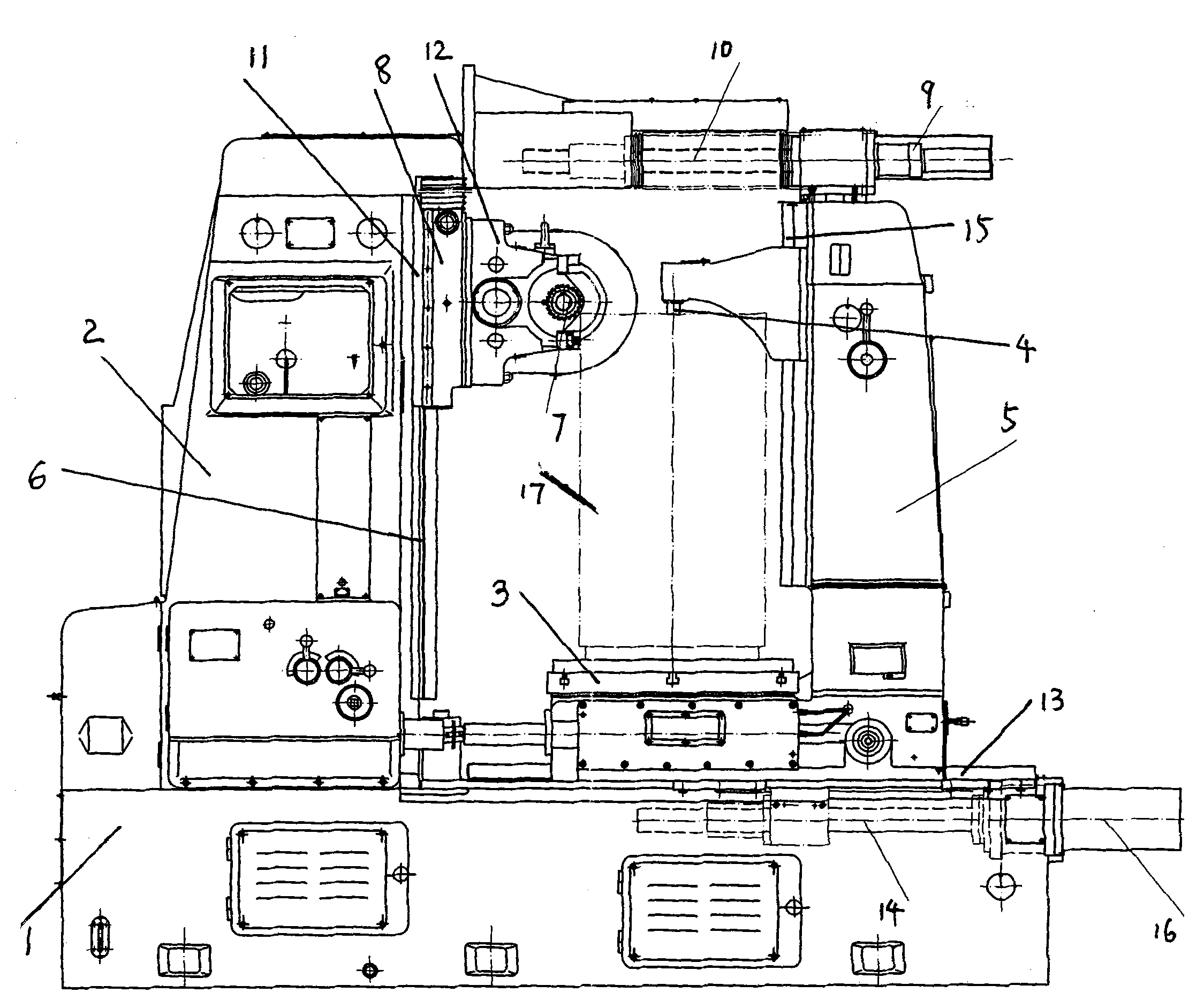

[0010] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention mainly includes: a machine base 1, a large column 2 on the machine base 1, a working turntable 3 for clamping a workpiece 17, a small column 5 with a top 4 connected to the working turntable 3, And be installed on the large column 2 and can move up and down along the large guide rail 6 on the large column, the slide plate frame 8 that can install the milling tool 7, horizontally placed between the described large column 2 upper end and the small column 5 upper end Adjust the screw mechanism of the position between the two; the screw mechanism shown in the figure is made up of an adjustable position screw rod 10 with a servo motor 9 .

[0011] figure 1 The large column 2 shown in the figure is fixedly placed on the machine base 1, and the slide frame 8 is composed of a slide plate 11 that can slide up and down on the large guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com