Ultra-narrow gap welding device and method for U-shaped flux strip constraining arc

A welding device and welding method technology, applied in arc welding equipment, electrode support devices, welding equipment, etc., can solve problems such as inability to effectively restrain the welding arc, inconvenient welding torch welding, and complex overall structure of the welding torch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

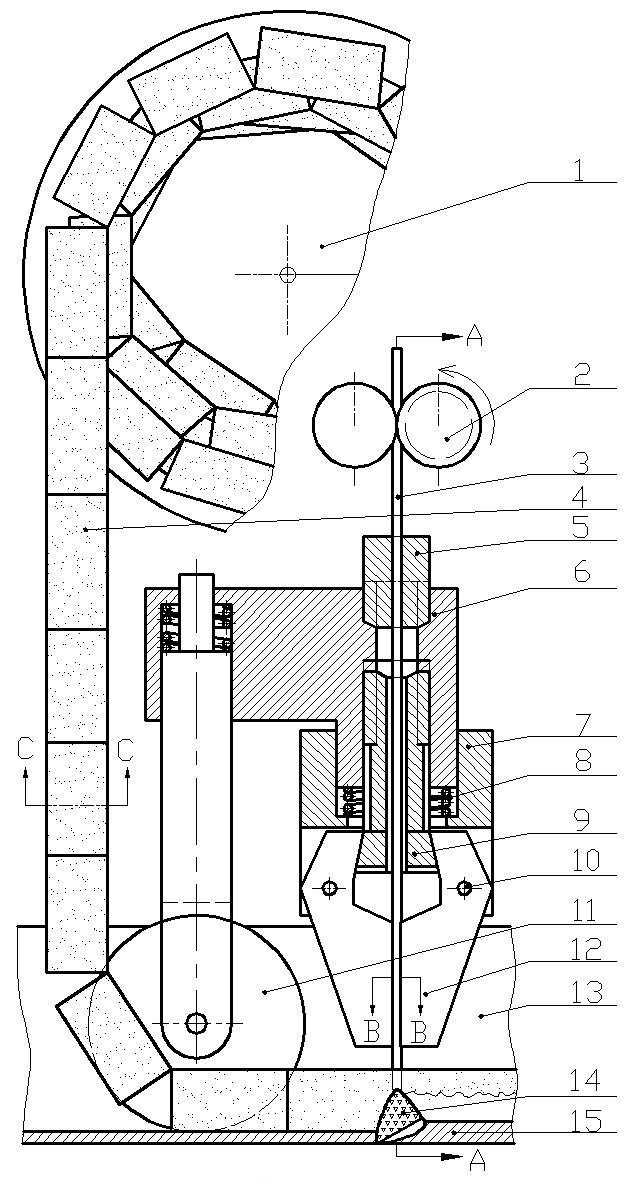

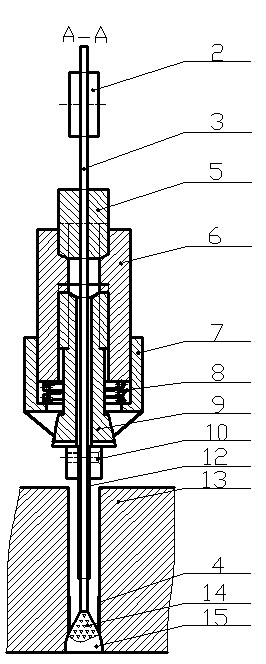

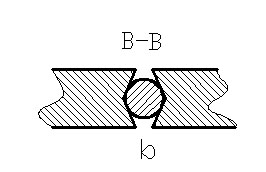

[0009] Such as figure 1 , figure 2 As shown, the U-shaped flux strip confined arc ultra-narrow gap welding device is composed of a flux strip laying mechanism and a welding torch. The U-shaped flux strip is composed of two parts: flux and steel wire mesh. On the top, the U-shaped flux belt 4 is pressed into the groove gap in front of the arc 14 through the pressure belt wheel 11 and is close to the side wall of the groove. On the base 7, the conductive sheet 12 can rotate around the screw 10, the compression spring 8 is set on the adjustment stem 9, and the adjustment stem 9 together with the compression spring 8 is installed on the welding torch support 6; the pressure belt wheel 11 is installed on the connecting rod, The upper end of connecting rod is arranged on the welding torch support 6 together with compression spring, and the size of the pressure band wheel 11 thickness is equal to the size of the exposed wire mesh width in the middle of the U-shaped solder band.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com