Equipment for fixing orientation of diamond blank with two conical ends

A diamond blank and cone-shaped technology, applied in the field of artificial diamond processing equipment, can solve the problems of reducing processing efficiency, multiple raw materials, increasing production costs, etc., and achieve the effect of reducing the amount of grinding, reducing production costs and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

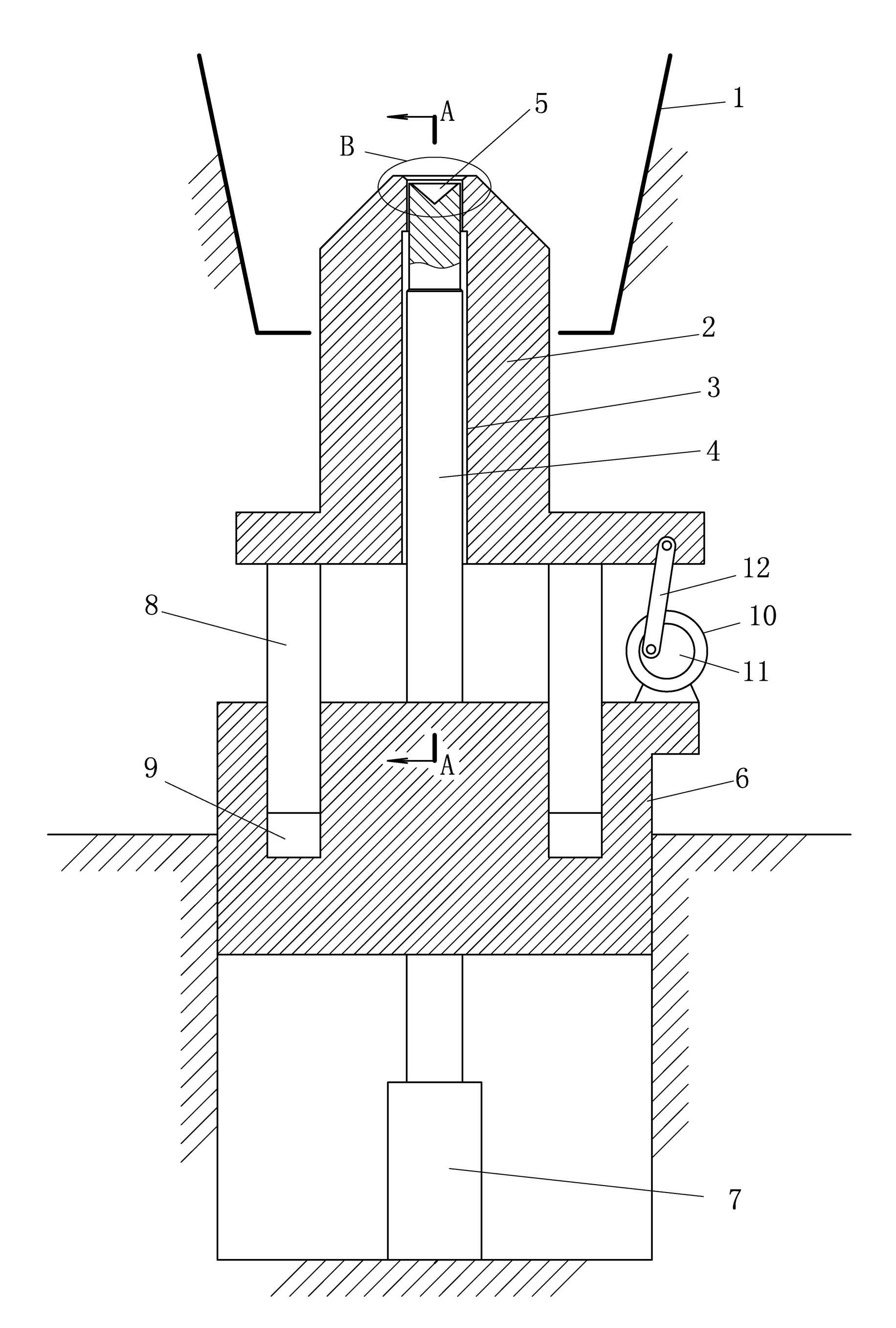

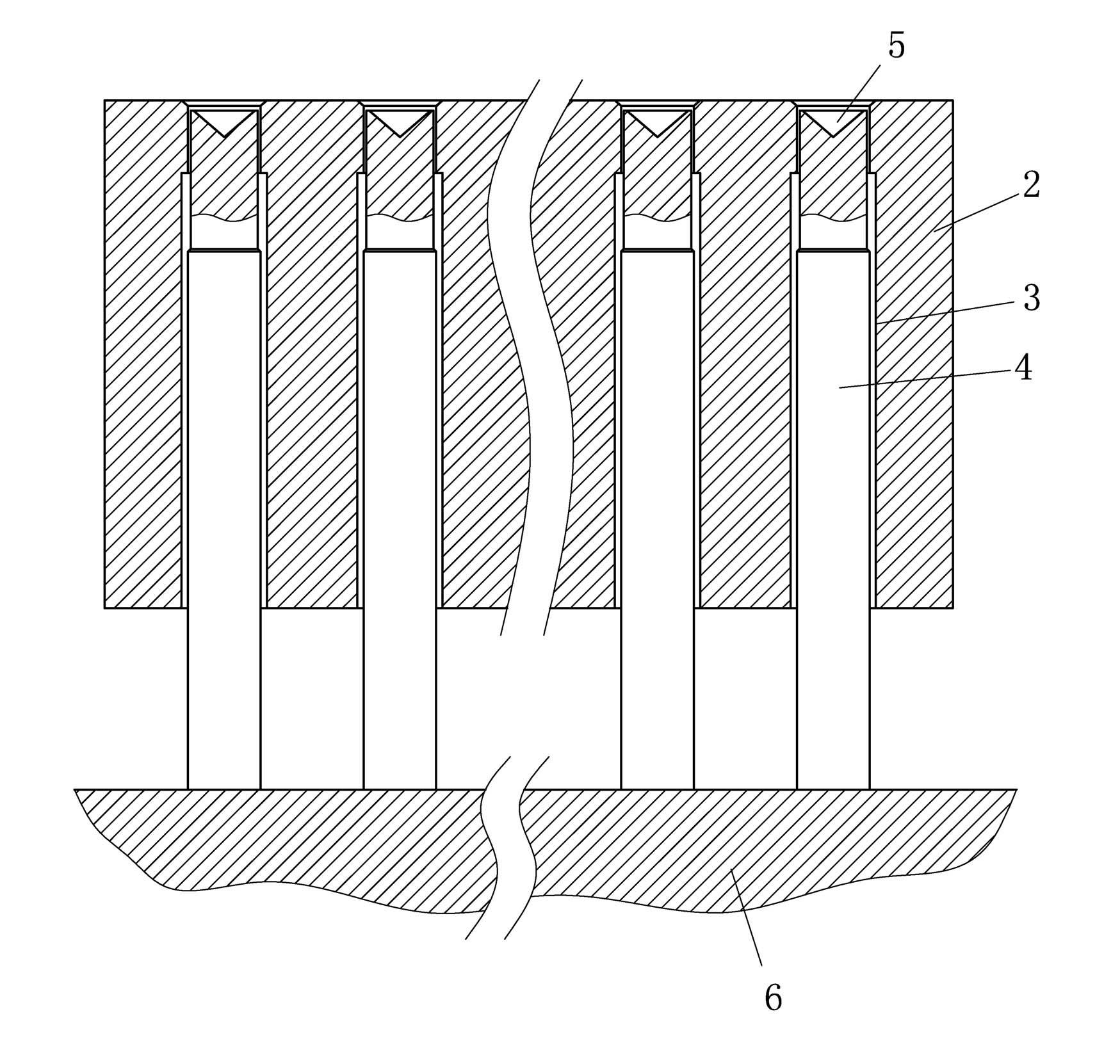

[0025] see figure 1 , figure 2 , the equipment for fixing the direction of the double-ended conical diamond blank, including a fixed frame and a material trough 1 for holding the diamond blank. Feed chute 1 is fixed on the frame. The bottom of the trough 1 is slidably matched with a vibrating part 2 that vibrates up and down. The vibrating part 2 extends into the trough 1 from bottom to top. The gap between the vibrating part 2 and the trough 1 is smaller than the diameter of the diamond blank, so as to prevent Diamond blanks fall out of the gap.

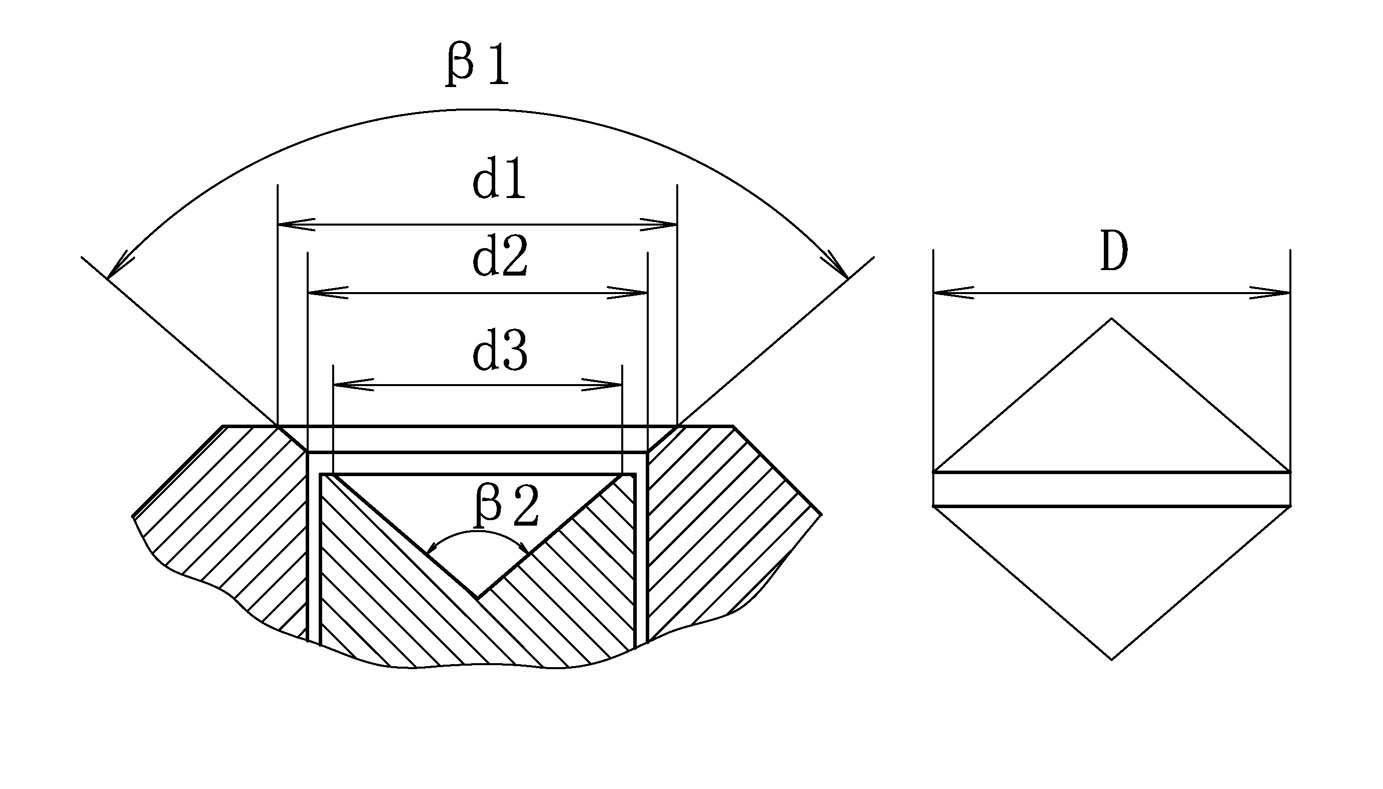

[0026] An upright through hole 3 is provided inside the vibrating element 2 , and the through hole 3 penetrates through the vibrating element 2 up and down. The top opening of the through hole 3 is a bell mouth, the diameter d1 of the large mouth end of the bell mouth is greater than the diameter D of the diamond blank, and the diameter d2 of the small mouth end of the bell mouth is smaller than the diameter D of the diamond bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com