Front edge impact, micro through passage and air film cooling structure of hypersonic vehicle

A technology of air film cooling and high-speed aircraft, which is applied in the direction of heat reduction structure, aircraft parts, fuselage, etc., which can solve the problems of inability to apply, high surface temperature, inability to meet the requirements of material strength and service life, and achieve the solution of inability to effectively cool Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

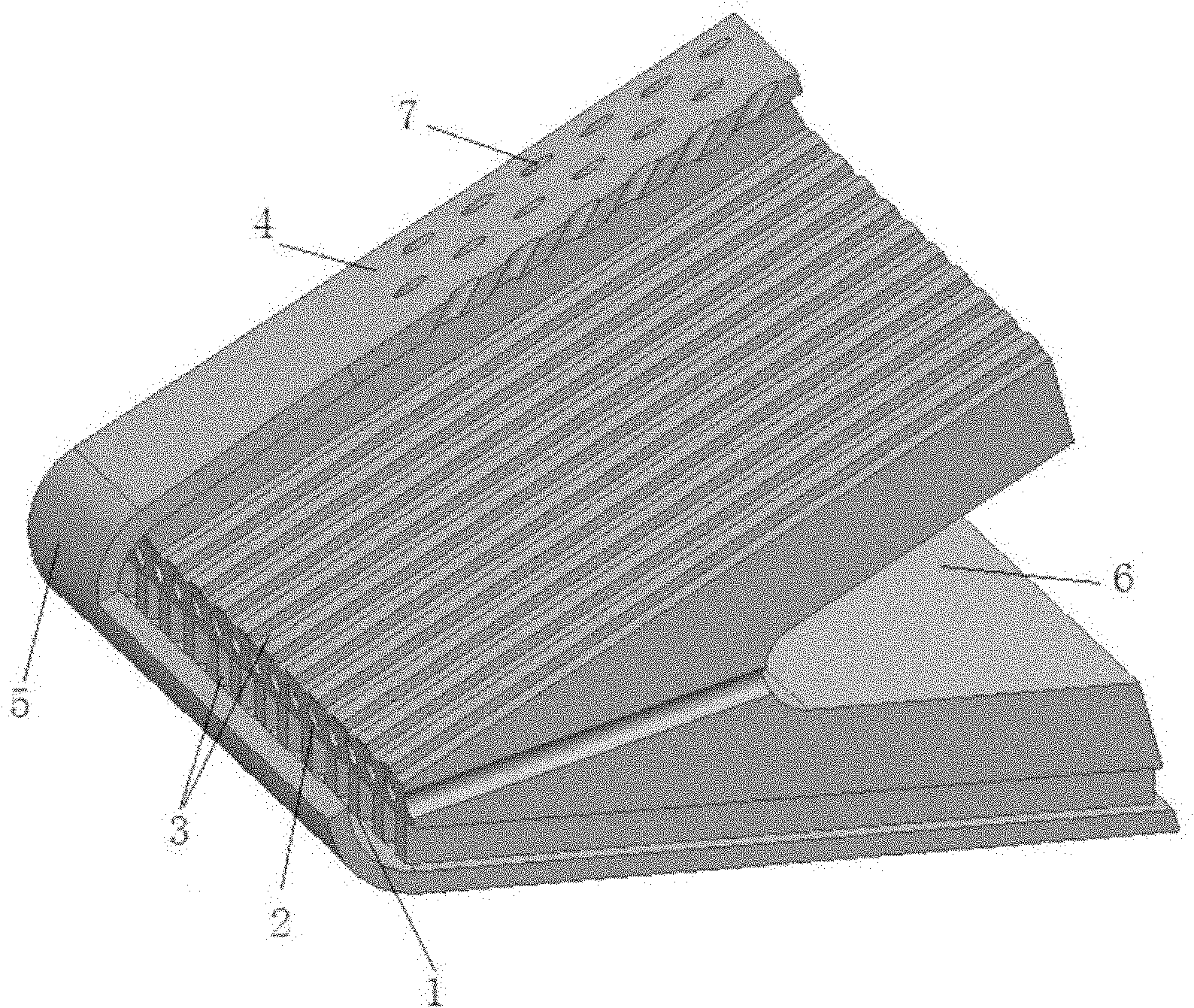

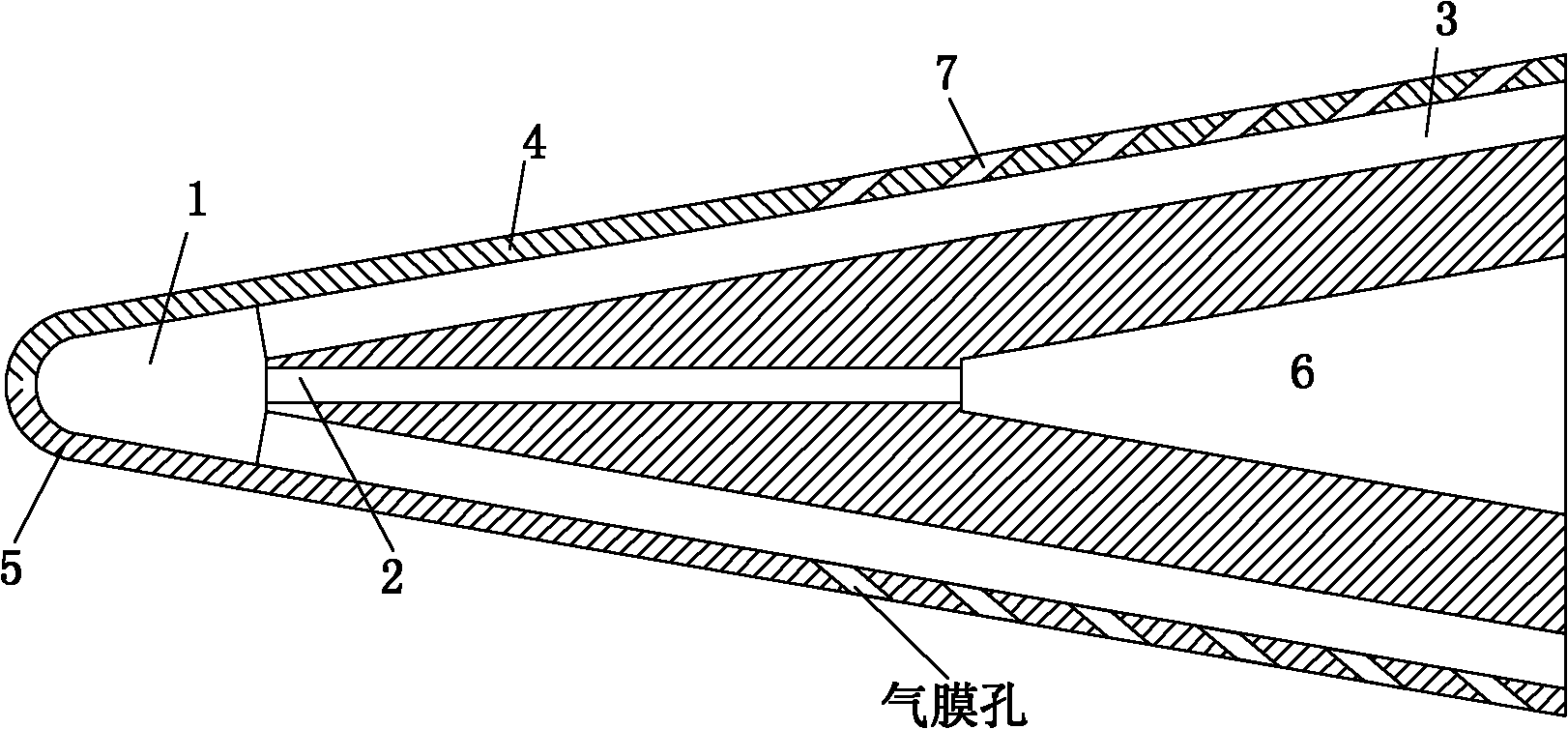

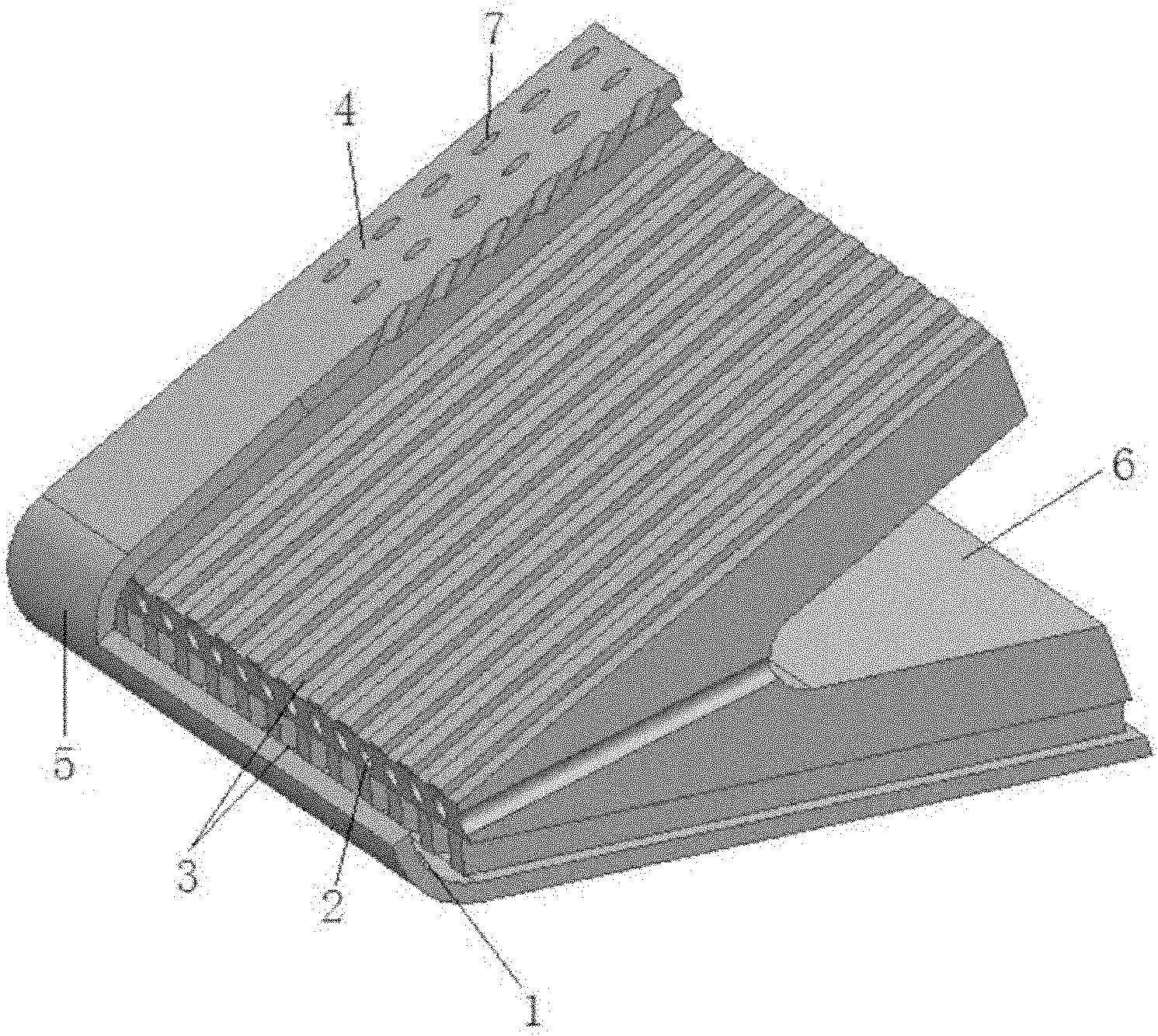

[0019] In the present invention, an impact chamber 1 is opened inside the leading edge 5 of the high-speed aircraft, and an impact hole 2 with a diameter of 0.5 mm to 1.0 mm is opened in the middle of the impact cavity 1. Small straight channels 3 with the same number of impact holes, the size of the inlet cross-section of the straight channels is (0.5mm~1.0mm)×(0.5mm~1.0mm), and a certain number of gas channels are set in the area where the surface temperature of the outer wall of the small straight channels exceeds 1200K. The film holes 7, the diameter of the air film holes 7 are 0.5 mm to 1.0 mm, and the distance between the air film holes 7 is 1.5 mm to 2.0 mm. The included angle between the gas film hole and the fluid flow direction in the tiny straight channel is 20°-50°, generally 30° is selected, and the angle can be slightly changed according to the strength of the heat exchange effect. The cooling medium enters the impact chamber 1 from the circular impact hole 2, fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com