Cordless hoister driven by double-U-shaped linear motor

A linear motor and hoist technology, which is used in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of easy car roll, difficulty in hoist braking, and difficulty in ensuring the working air gap of the motor. Avoid the car squatting or overhead accident, facilitate synchronous operation and redundant design, and save installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

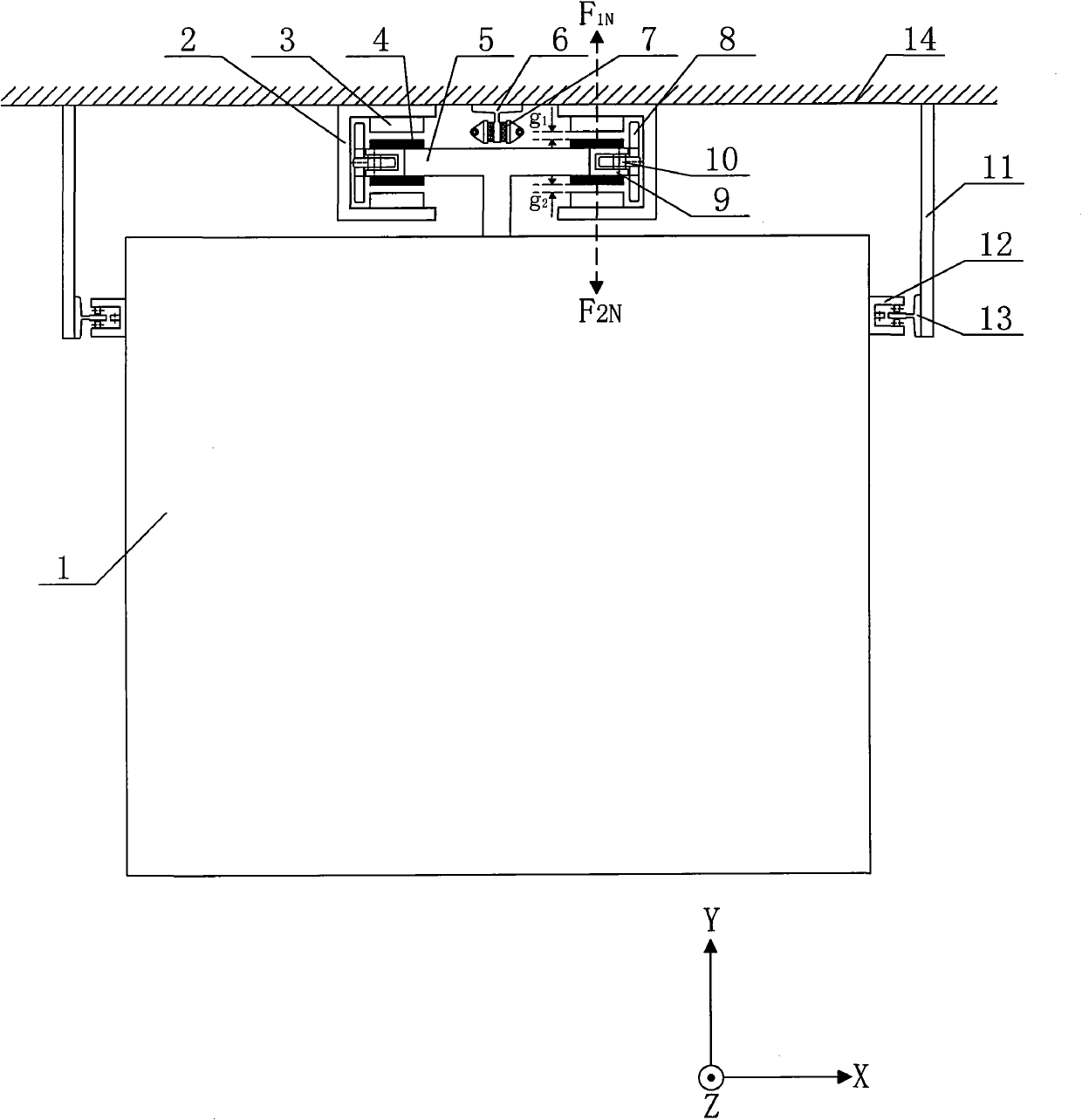

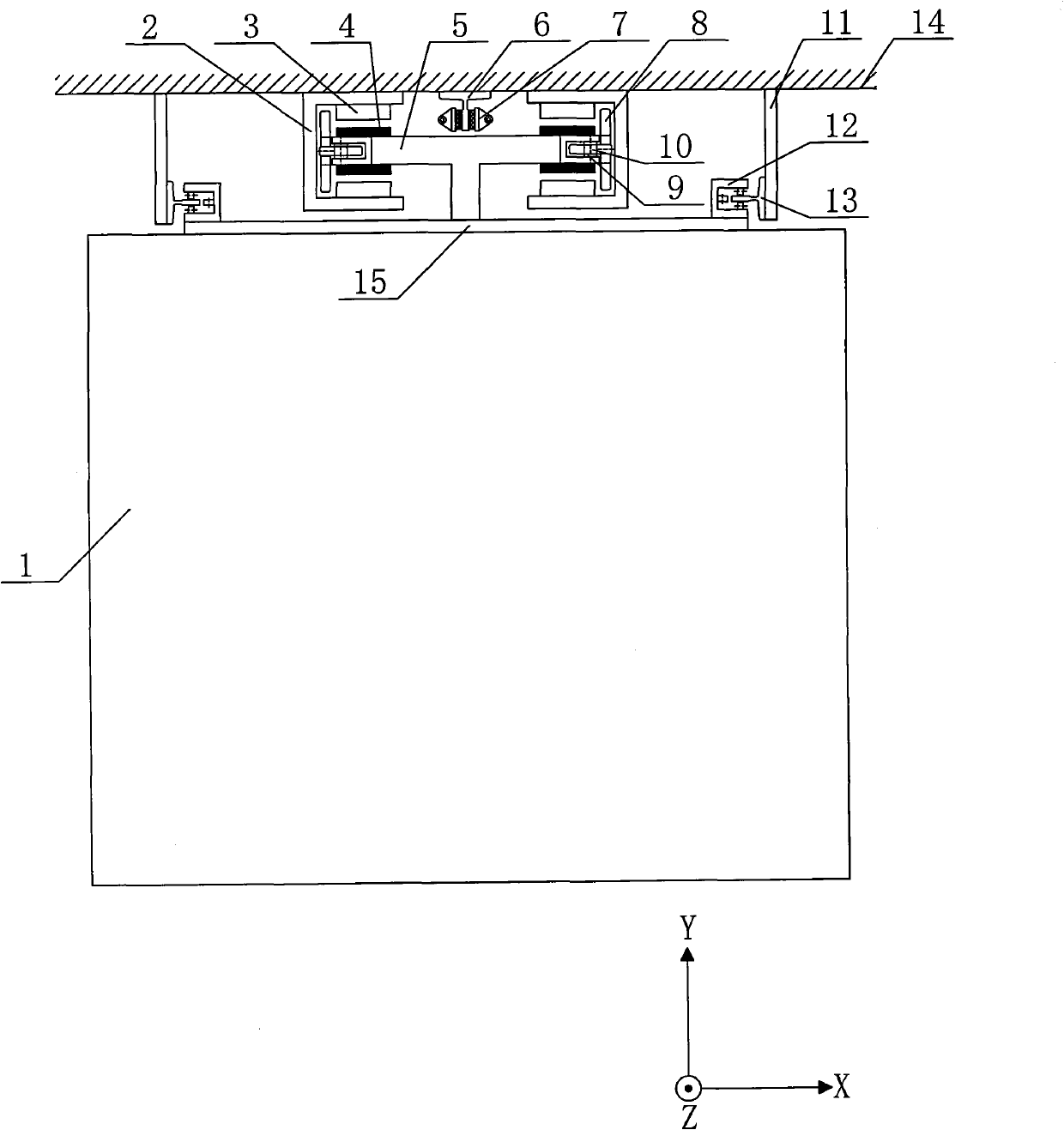

[0031] As shown in Figure 1 (A~D), four types of cordless hoist schemes driven by double U-shaped linear motors are provided. It is a cross-sectional schematic diagram of a cordless hoist that adopts different schemes in braking, positioning and motor arrangement from Figure 1(A).

[0032] Take Fig. 1 (A) and Fig. 2 (A-C) as examples below to describe in detail.

[0033] As shown in Figure 1(A), the cordless hoist driven by double U-shaped linear motors includes car 1, linear motor drive device, brake device, positioning guide device, safety gear protection device and buffer device, and is fixed by The power supply cable on the shaft inner wall, the power supply rail contact or the power supply rail non-contact mode provide the power supply of the hoisting motor, the car 1, and the caliper brake 7.

[0034]The openings of two U-shaped fixed beams 2 are arranged opposite to each other and fixed on the installation base 14. The T-shaped motor mover mounting seat 5 is connected ...

Embodiment 2

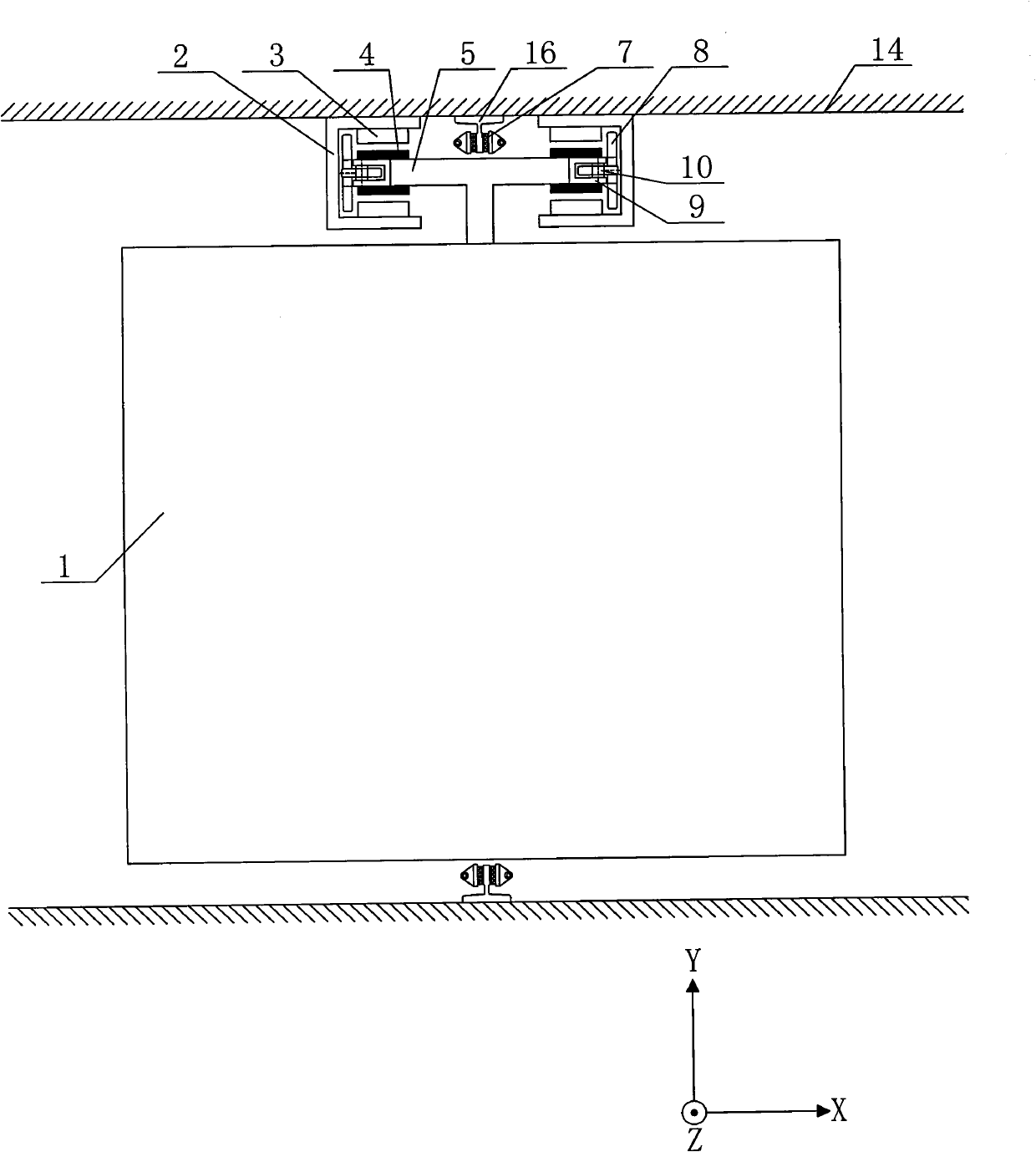

[0054] Such as Figure 5 As shown, no caliper brake device is provided between the double U-shaped linear motors. The caliper brake 7 and the guide shoe 12 share a brake guiding mixed T-shaped rail 16 . The brake-guiding hybrid T-shaped rail 16 is used not only for braking but also for positioning and guiding the car. It is located on both sides of the car and basically on the same plane as the center of gravity of the moving part of the cordless hoist. The cordless hoist is provided with two caliper brakes 7 and is located above the guide shoe 12 . Other structures are the same as in Figure 1(A).

Embodiment 3

[0056] As shown in Figure 6 (A~C), three types of cordless hoist schemes driven by double U-shaped linear motors are provided. Figure 6(A) is a schematic cross-sectional view of a cordless hoist scheme. It is a cross-sectional schematic diagram of a cordless hoist that adopts a different scheme from that in Fig. 1(A) in terms of braking and positioning.

[0057] Take Fig. 6(A) as an example below to describe in detail.

[0058] In the cordless hoist, two U-shaped fixed beams are arranged back to back, with openings facing outwards, forming an "I"-shaped fixed beam 17, and the braking T-rail 6 is arranged on the top surface of the "I"-shaped fixed beam 17. The motor mover mounting base is composed of two L-shaped motor mover mounting bases 18, and is connected to the car 1 respectively through the car frame. Other structures are the same as in Figure 1(A).

[0059] The differences in braking and positioning methods between Fig. 6 (B-C) and Fig. 1 (A) will be further explained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com