Method for self-assembling nanoparticles by means of patterned polyelectrolyte membrane

A polyelectrolyte, nanoparticle technology, applied in the nano field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

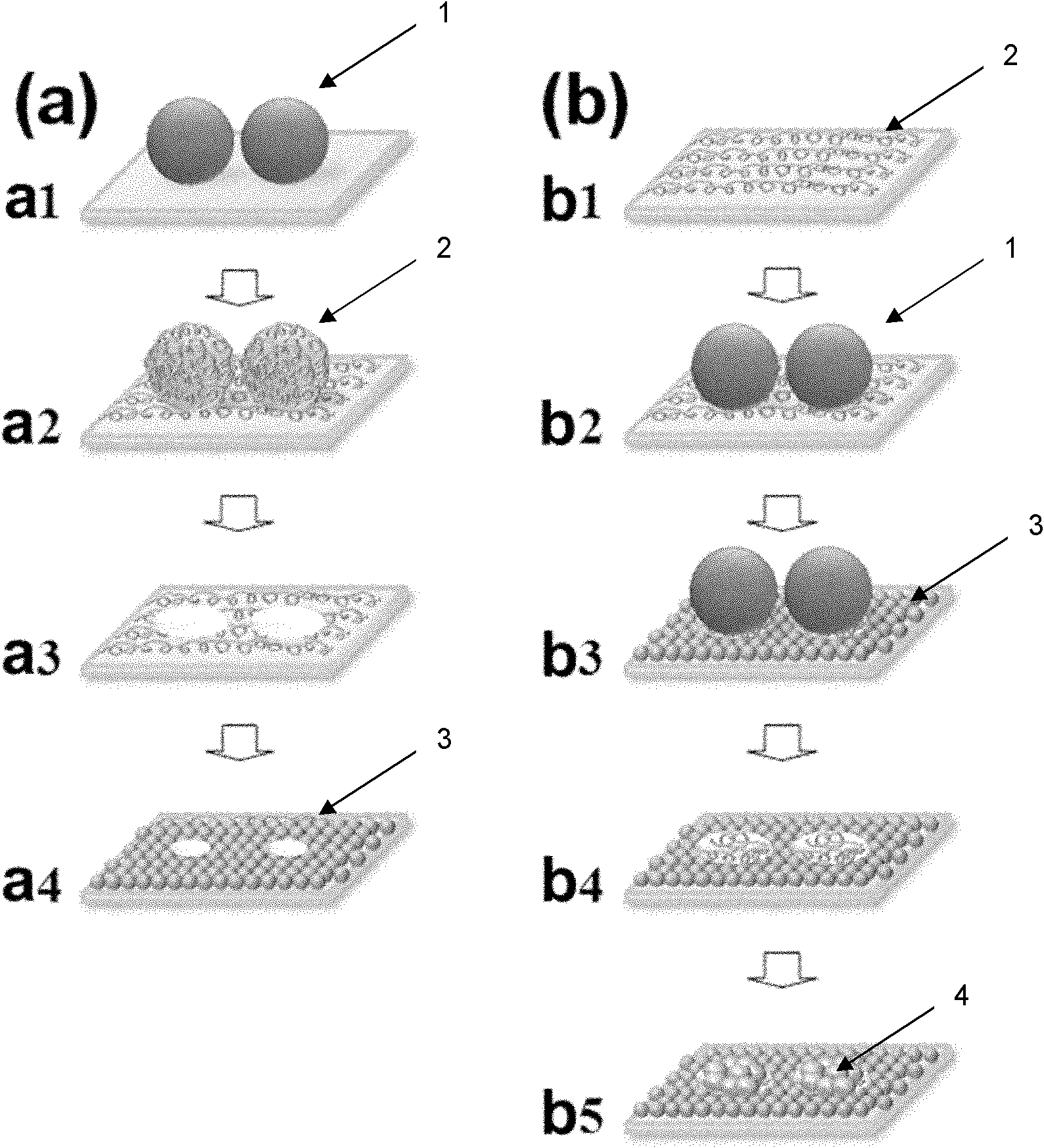

[0030] Embodiment 1 (each step is the same as figure 1 a):

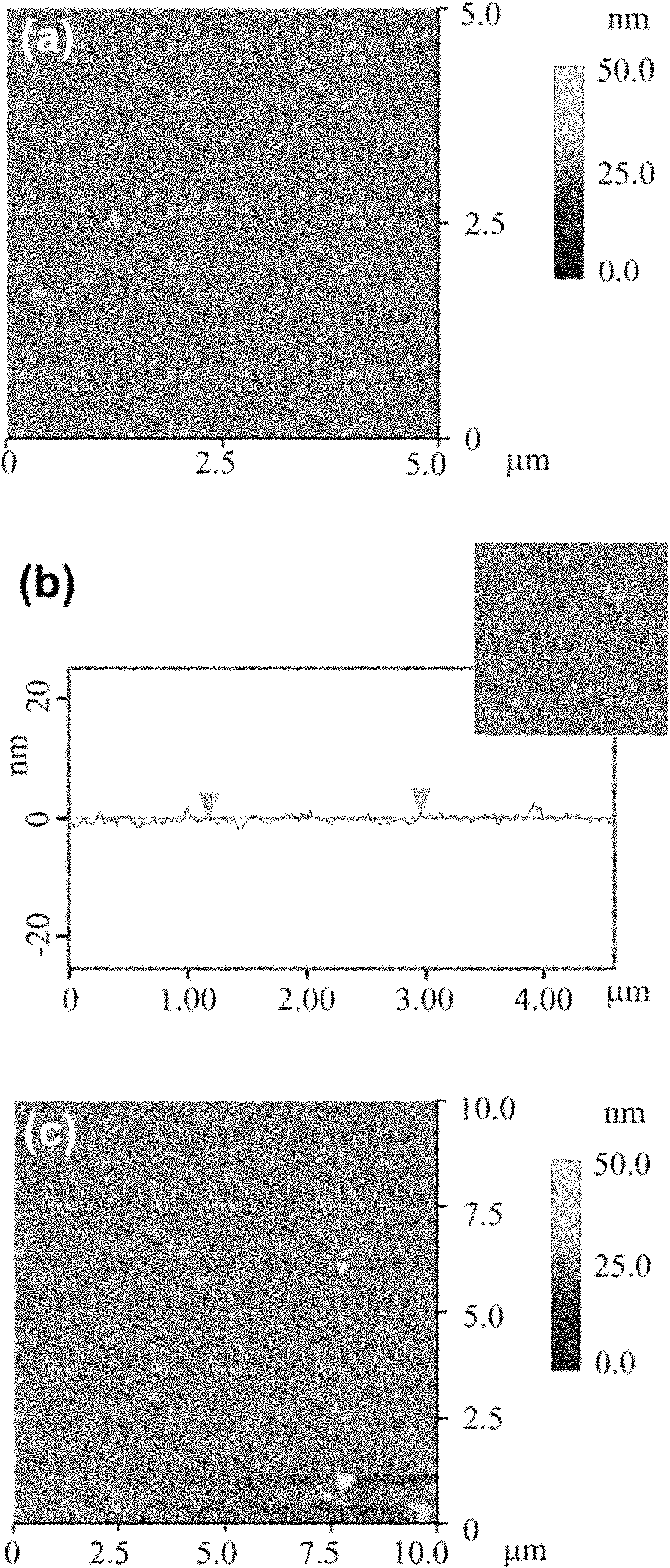

[0031] (1) the polystyrene microsphere emulsion that the diameter of 1% monodisperse is 600 nanometers is dispersed to the gas-liquid interface to form the thin film that microsphere monolayer orderly arranges with the monodisperse diameter of 1%; The film was transferred to a glass slide and dried naturally;

[0032](2) Soak the glass flakes arranged on the surface covered with microspheres in an aqueous solution of 0.5% PDDA polyelectrolyte molecules for 0.5 hours, and modify a layer of polyelectrolyte molecules on the surface of the microspheres and glass flakes, with a thickness of 0.5 to 1.5 Nano;

[0033] (3) Immerse the surface-modified microspheres and PDDA glass flakes into chloroform and ultrasonically clean them for 30 seconds to dissolve the microspheres, and the PDDA molecules modified on the surface of the microspheres will fall off simultaneously with the dissolution of the microspheres. The surface...

Embodiment 2

[0035] Embodiment 2 (each step is the same as figure 1 b):

[0036] (1) Soak the glass flake in an aqueous solution of 0.5% PDDA polyelectrolyte molecules for 0.5 hours, and modify a layer of polyelectrolyte molecules on the surface of the glass flake with a thickness of 0.5 to 1.5 nanometers;

[0037] (2) the polystyrene microsphere emulsion that the diameter of 1% monodisperse is 600 nanometers is dispersed to the gas-liquid interface to form the thin film that microsphere monolayer orderly arranges with the monodisperse diameter of 1%; The film was transferred to a PDDA-modified glass slide and dried naturally;

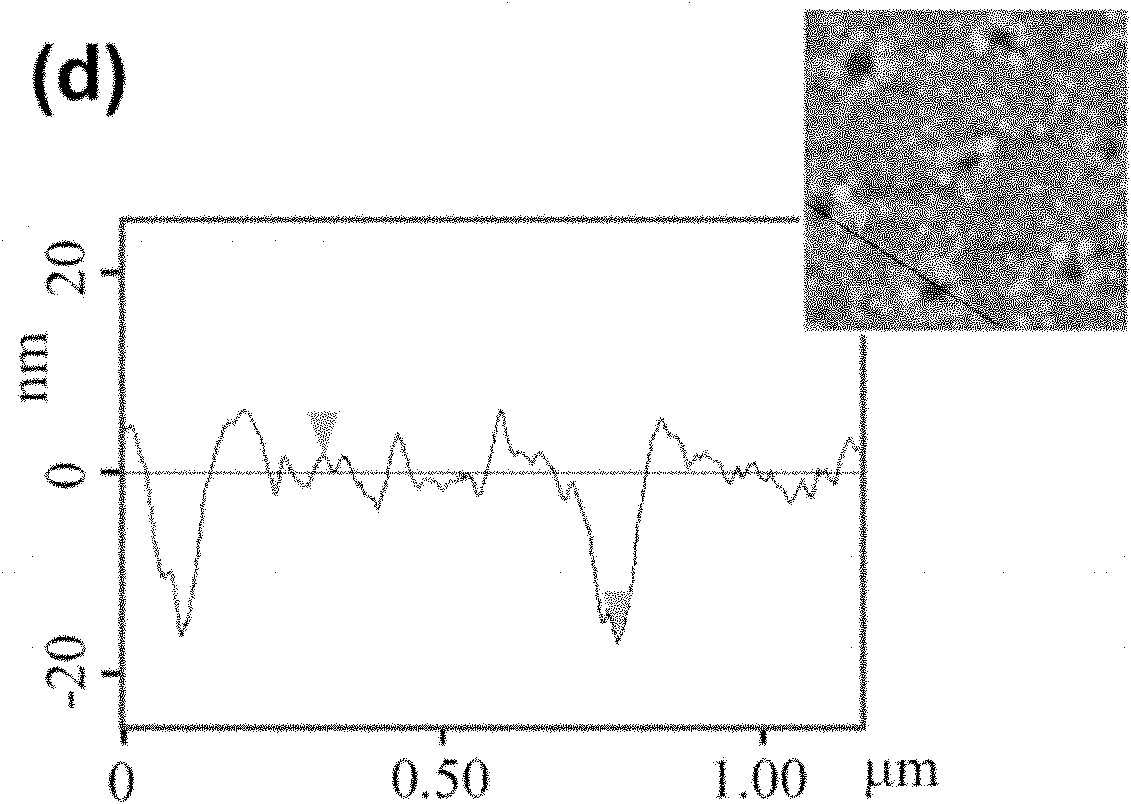

[0038] (3) Soak the glass flakes of surface-modified PDDA and microspheres in a monodisperse 17-nanometer gold sol for 2 hours, and modify a layer of gold nanoparticles on the PDDA molecules;

[0039] (4) Immerse the glass sheet of surface-modified PDDA, microspheres and gold nanoparticles into chloroform and ultrasonically clean for 30 seconds to dissolve the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap