Method for constructing overpass gate-type pier spanning over electrified railway

A technology for electrified railways and construction methods, applied in bridges, bridge parts, bridge construction, etc., can solve the problems affecting the normal intake of the pantograph of electric locomotives, the difficulty of vehicle climbing, and the large slope of the bridge deck. Remarkable benefits, labor-saving vehicle climbing, and reduction of engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

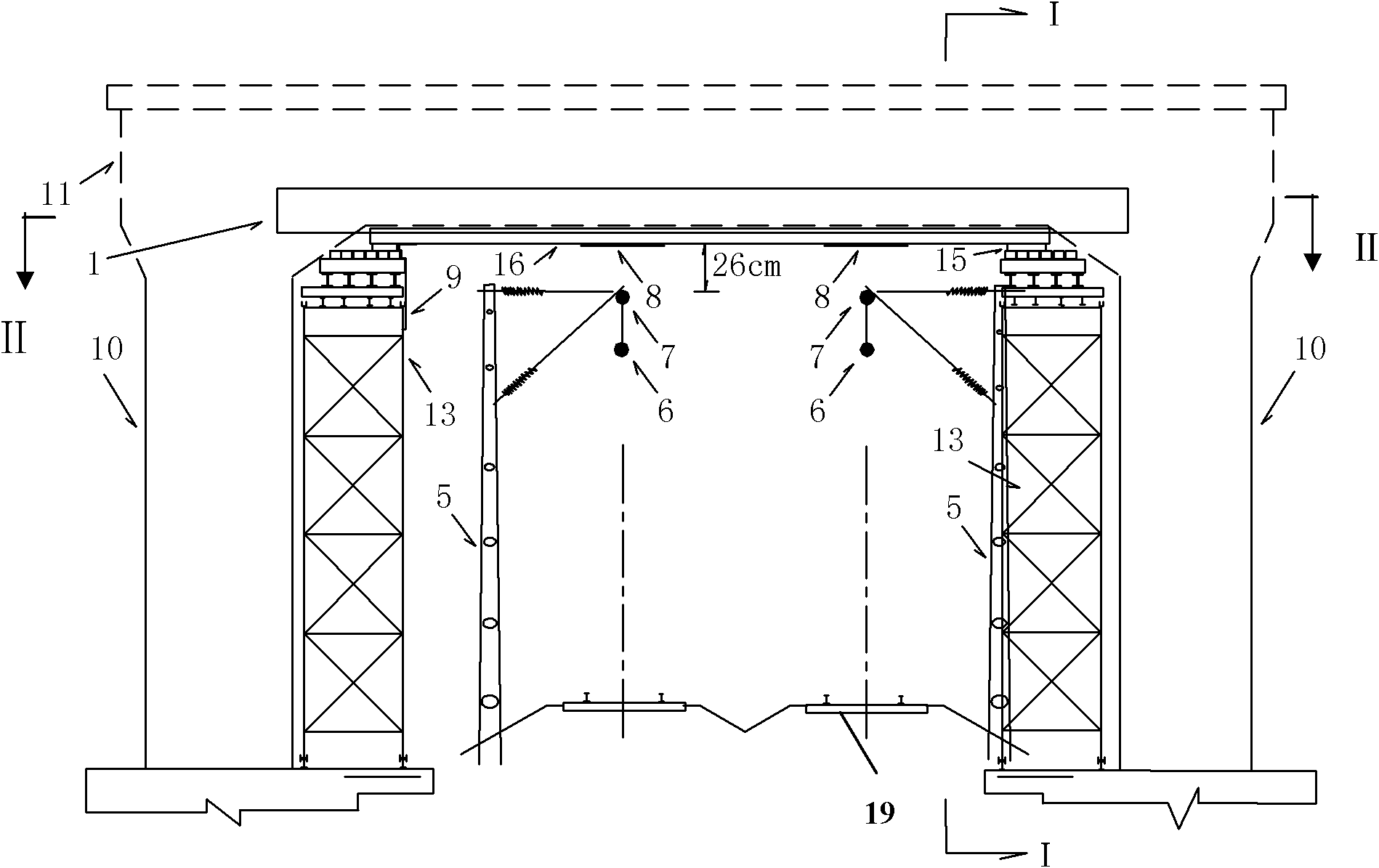

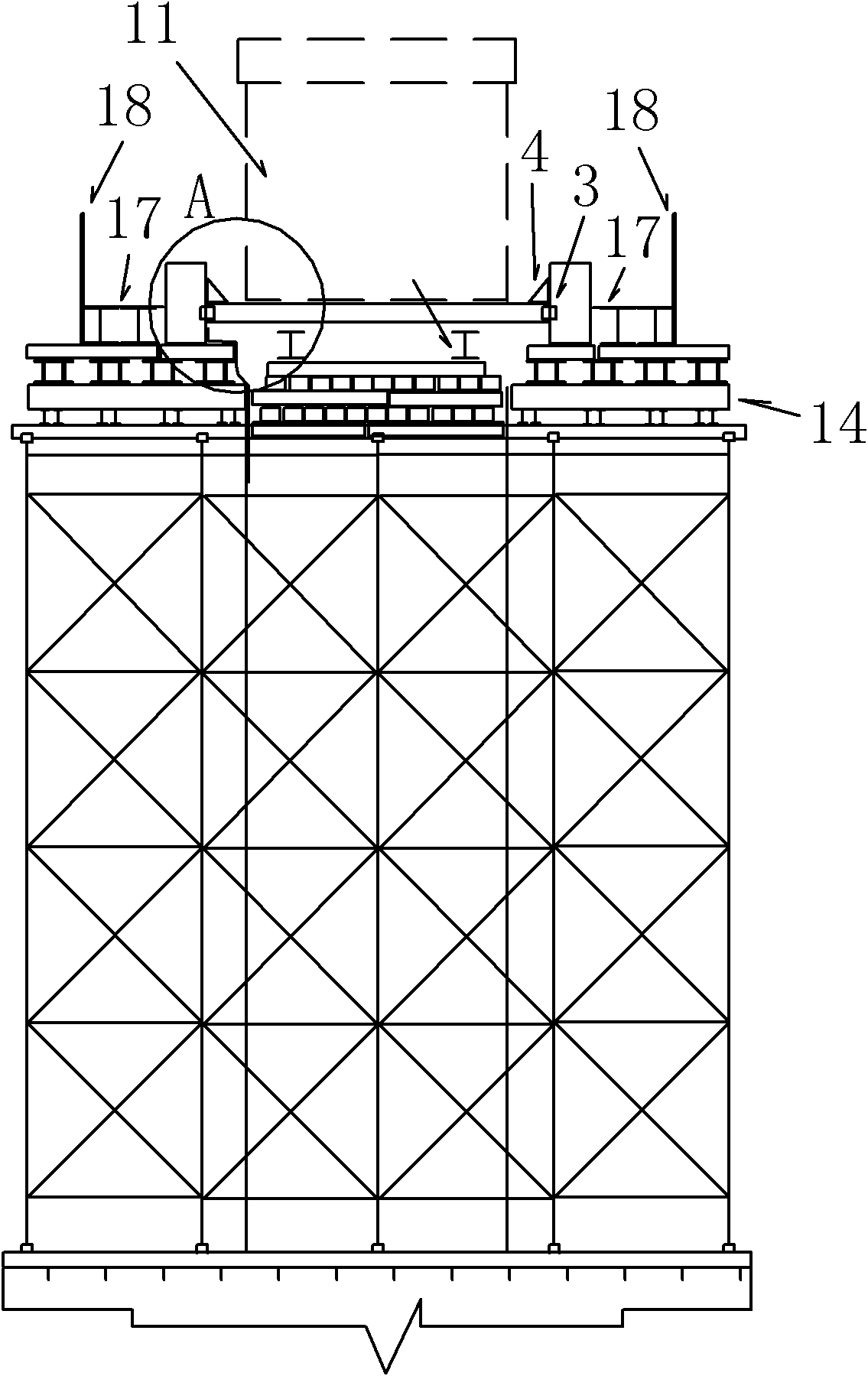

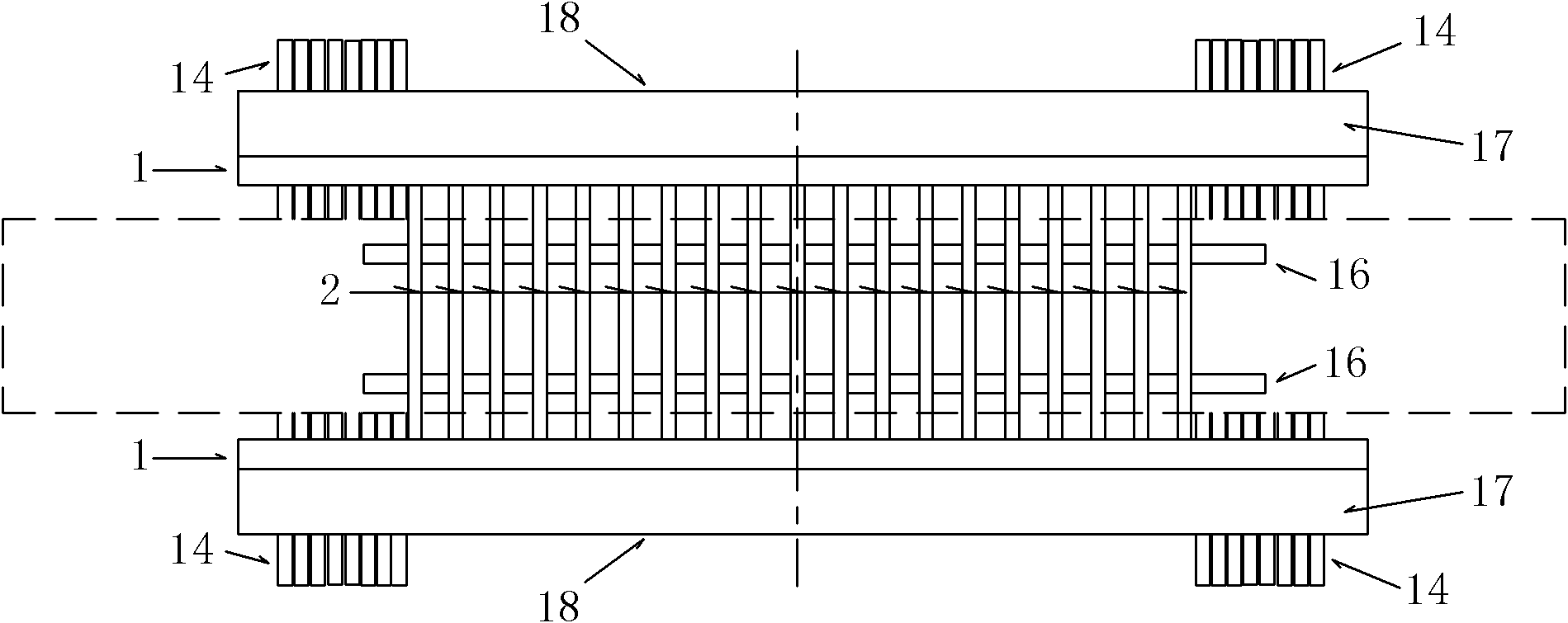

[0031] The following will describe in detail the construction method for the portal pier of the overpass bridge across the electrified railway provided by the present invention with reference to the accompanying drawings and specific embodiments.

[0032] like Figure 1-Figure 4 As shown, the construction method for the portal pier of an overpass bridge across an electrified railway provided by the present invention comprises the following steps in sequence:

[0033] 1) First, build a pier 10 on the outside of the catenary pillar 5 and the outside of the other side of the rail 19;

[0034] 2) Between each pier 10 and the catenary pillar 5, erect a column 13 formed by connecting rods;

[0035] 3) On the top of each column 13, stack multiple square steel layers 14 in a crisscross manner, and the height of the square steel layers 14 needs to be higher than the height of the bearing cable 7;

[0036] 4) Place a cube-shaped steel plate sandbox 15 on the top surface of the uppermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com