Light emitting diode module

A technology of light-emitting diodes and light-emitting chips, which is applied to the semiconductor devices of light-emitting elements, light sources, electric light sources, etc., can solve the problems of not saving energy, increasing the cost of materials and processing and assembly, and being unable to effectively control the light direction of light-emitting diode components, etc., to achieve reduction Material, effect of reducing the amount used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

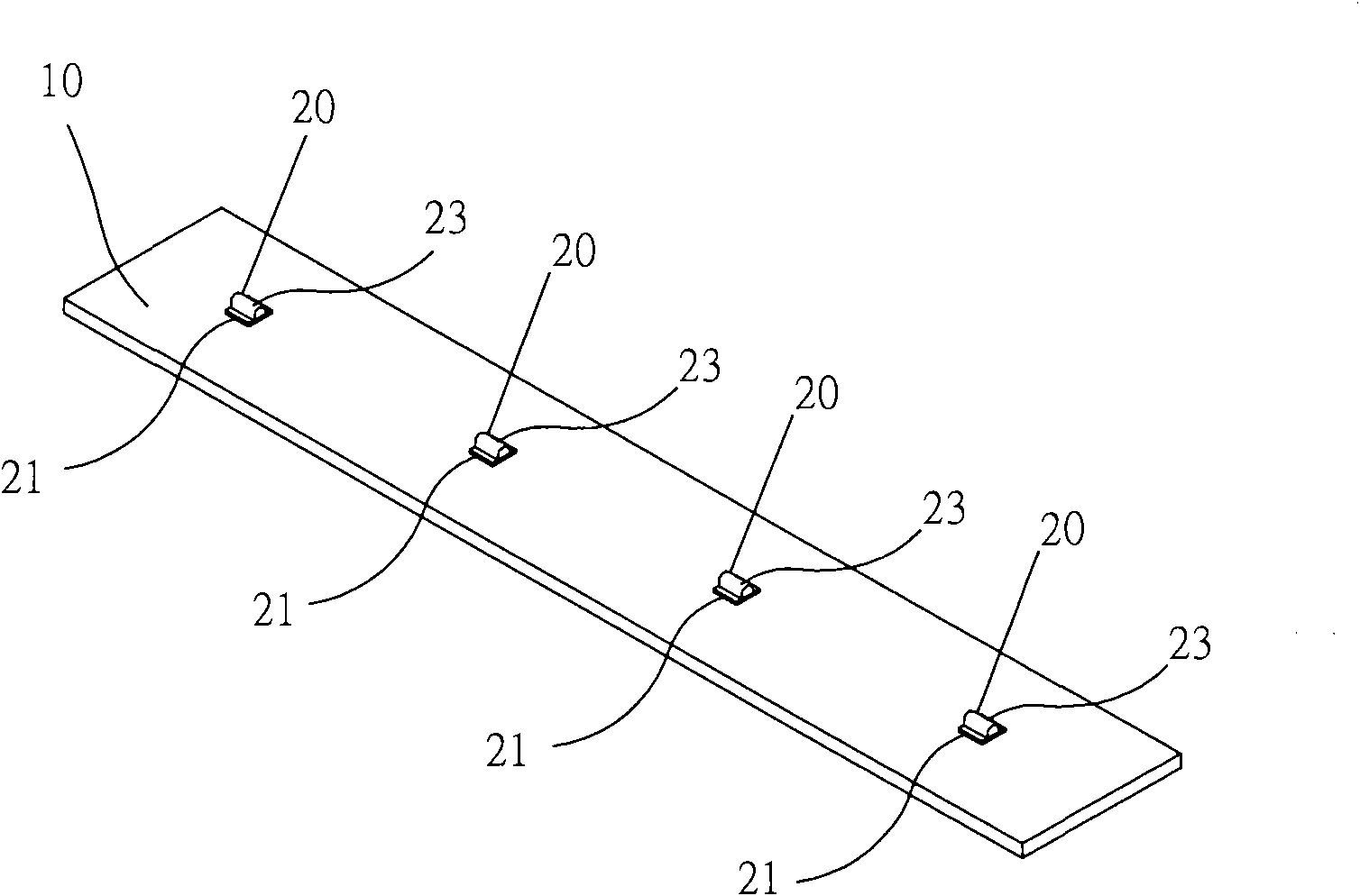

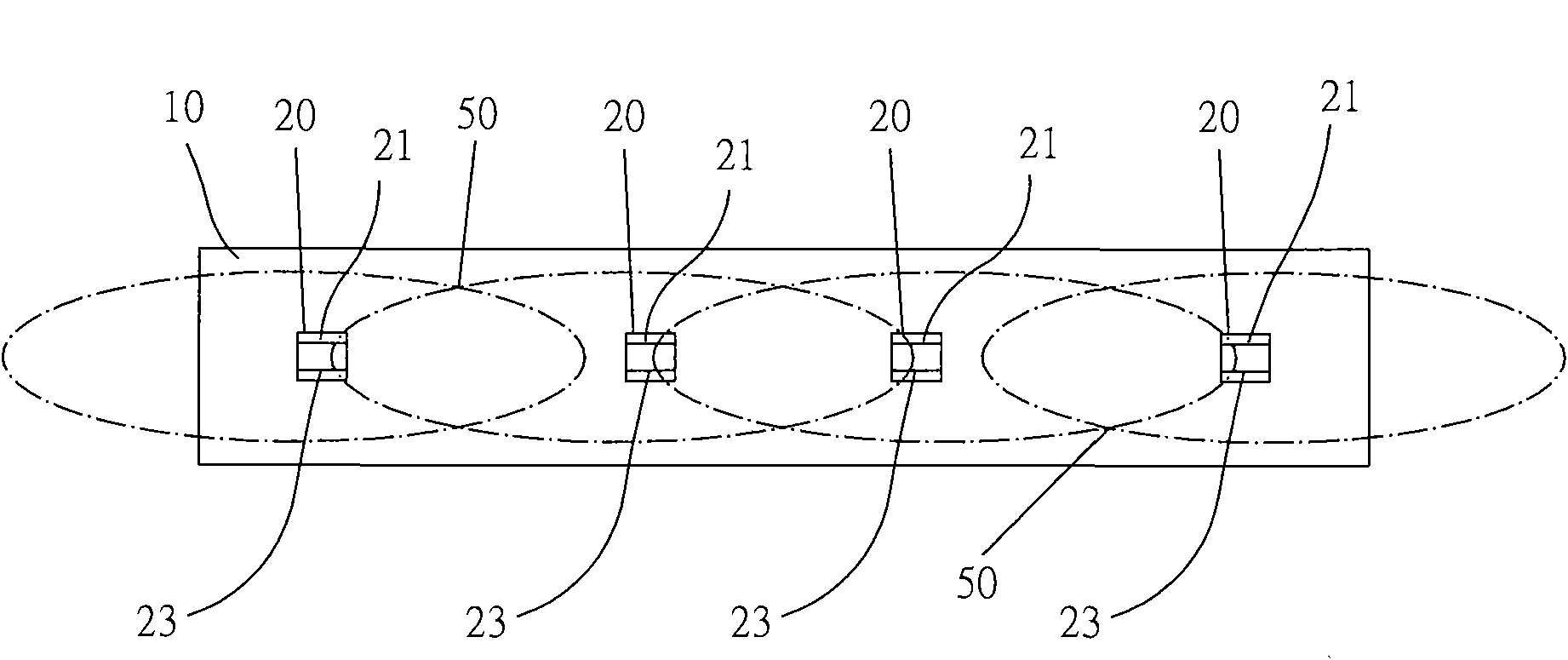

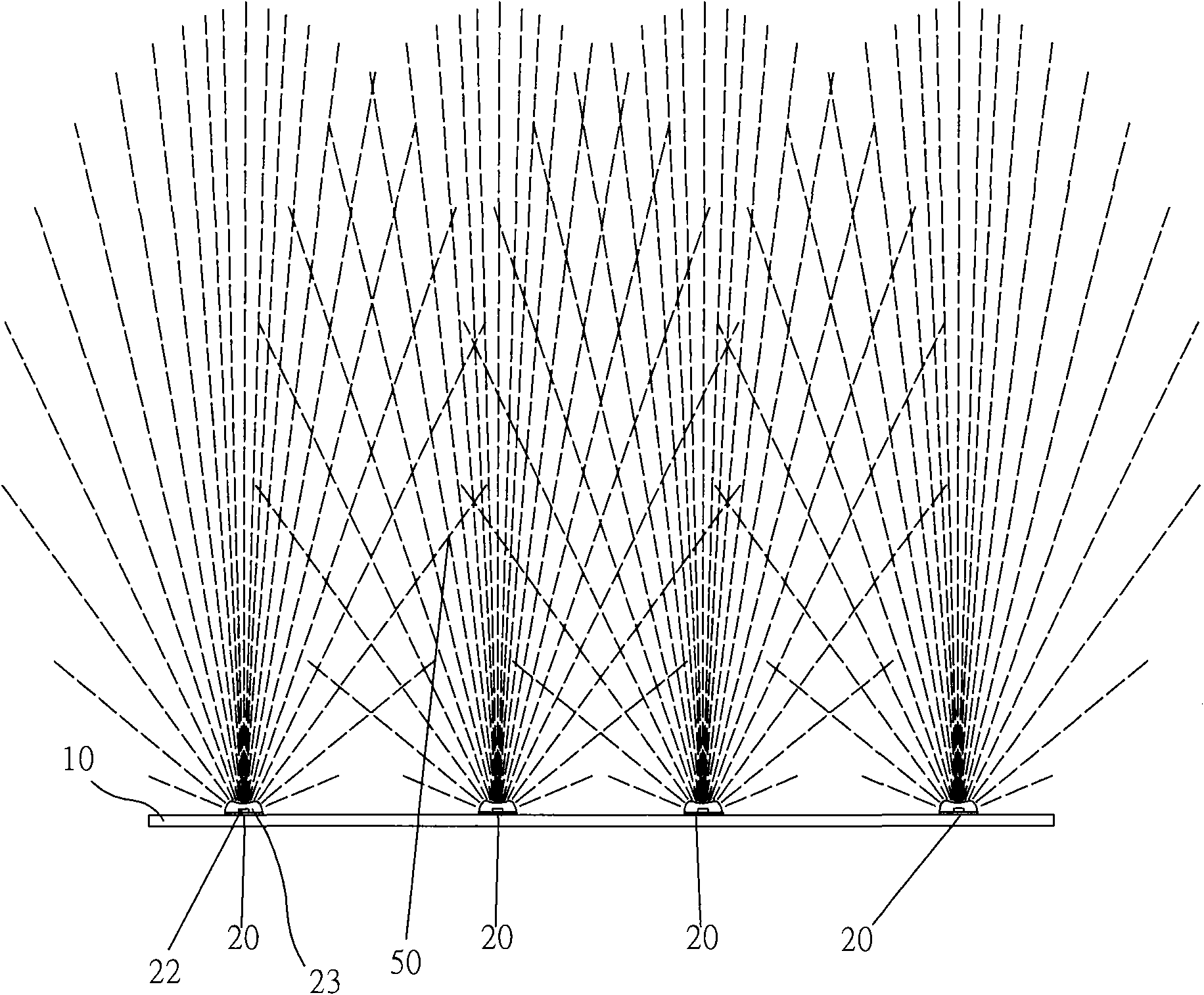

[0033] Such as figure 1 , 2 , 3, and 4, a light emitting diode module provided by the present invention is provided with four first light emitting diode assemblies 20 on a body 10, and each first light emitting diode assembly 20 is provided with at least A light-emitting chip 22 and a light-transmitting component 23 for transforming the light source of the light-emitting chip 22 into a long light shape. Each first light-emitting diode assembly 10 is arranged in a space sufficient to form a continuous light shape.

[0034] When the light-emitting diode module is in use, each light-transmitting component 23 can turn the light source of the first light-emitting diode component 20 to be horizontally and longitudinally narrowed, making a relatively long light shape, and relatively increasing the light 50 toward the distance Of course, the above-mentioned light-transmitting components 23 can also convert the light source of the first light-emitting diode component 20 into a long light s...

Embodiment 2

[0037] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that: when the present invention is implemented, each light-transmitting component 23 has a base composed of two corresponding long sides 231 and two corresponding short sides 232. The top edge of the base is in an arc convex shape, and the light-transmitting component 23 is composed of a packaging material 23 a directly covering the outside of the light-emitting chip 22.

Embodiment 3

[0039] Such as Image 6 , 7 As shown, the difference between this embodiment and Embodiment 1 or 2 is that the light-transmitting component 23 is composed of an optical lens 23b disposed on the substrate 21.

[0040] In the structure in which each light-transmitting component 23 is composed of an optical lens 23b provided on the substrate 21, each light-transmitting component 23 can be further provided with a recess 233 at its base for accommodating the light-emitting chip 22 for The light source generated by the light emitting chip 22 is effectively received, and the structural integrity of the first light emitting diode assembly 20 is increased.

[0041] Between the optical lens 23b of each first light-emitting diode assembly 20 and the substrate 21, there are two sets of positioning structures composed of positioning bumps 234 and positioning holes 211, so as to quickly fix the light-transmitting component 23 and the light-emitting chip. The relative position of 22 can achieve b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com