Electromagnetic pushing-beating-type object-detecting device

一种物体检测、电磁的技术,应用在物位传感器领域,能够解决产生误信号、起振电压高、耗用材料多等问题,达到减少布线成本、功耗降低、节省材料的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

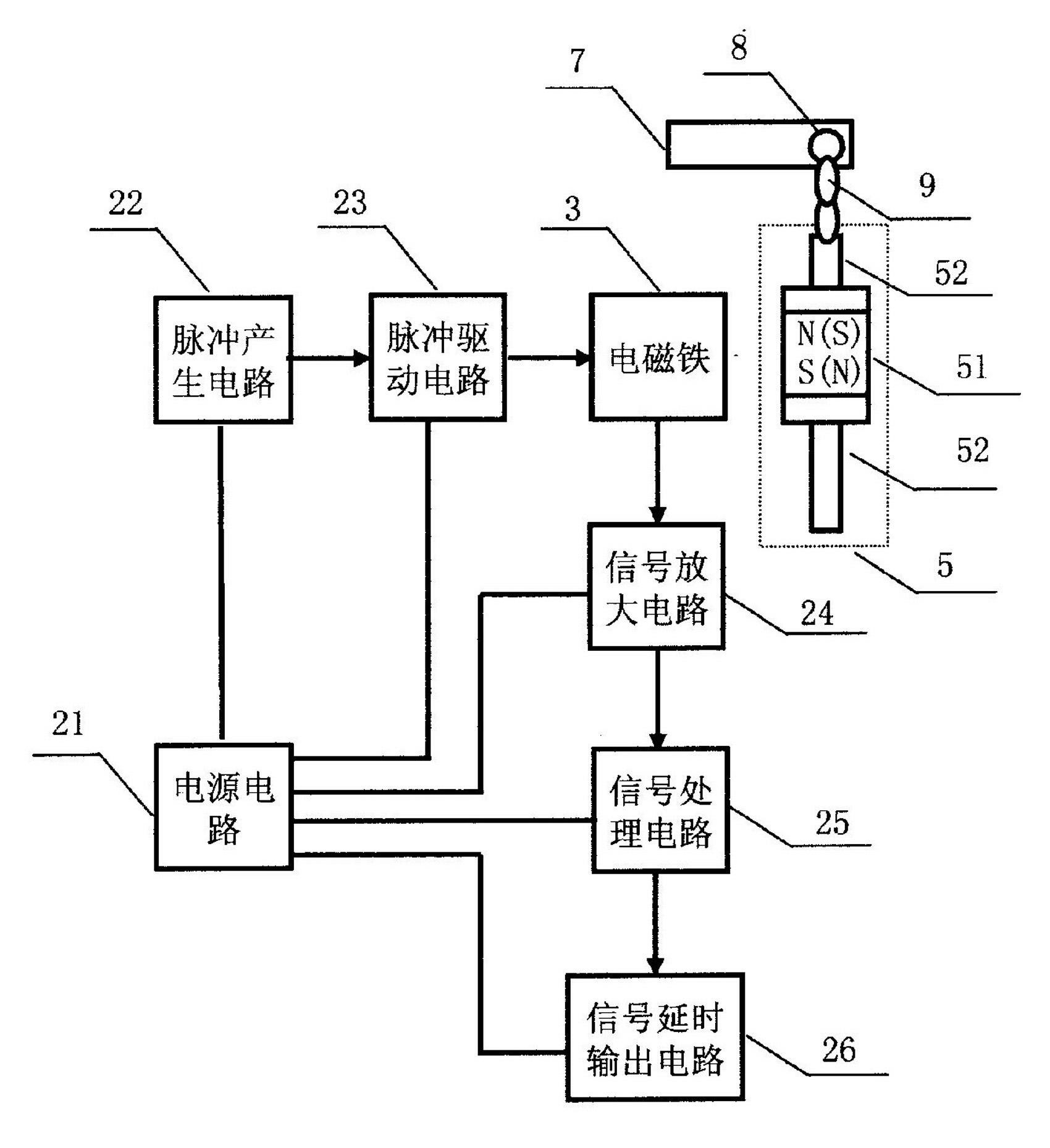

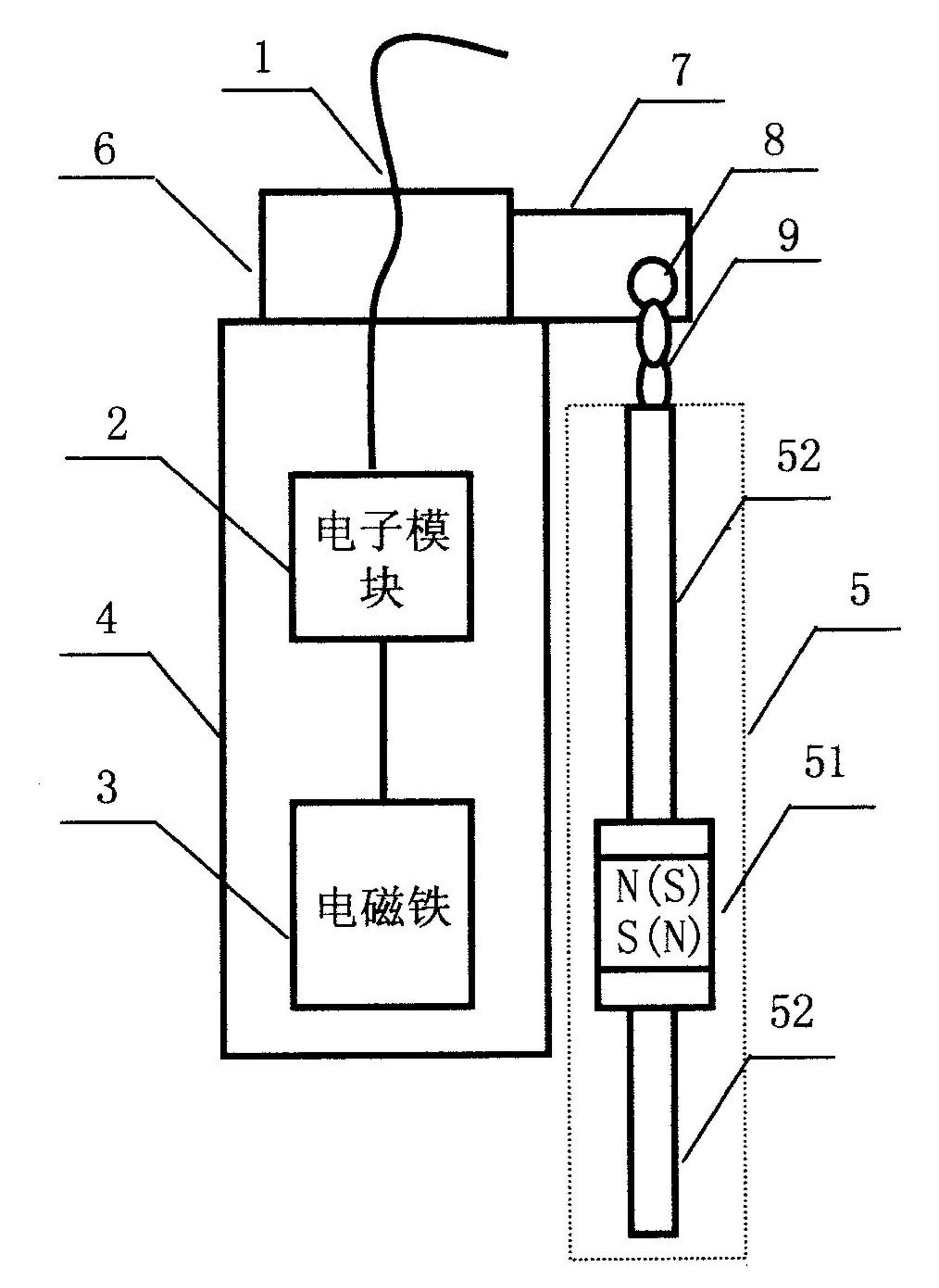

[0034] exist figure 1 , figure 2 , Figure 6 , Figure 7 Among them, the electromagnetic knocking type object detection device belongs to the top vertical installation type, and is designed to be composed of a lead wire 1, an electronic module 2, an electromagnet 3, a magnetic percussion component and a casing 4, and a lead wire interface 6 is provided on the top of the casing 4. The lead-out line interface 6 has a pipe thread, and one end of the line tube is screwed into the lead-out line interface 6, and the other end is fixed on the warehouse roof plate 12. The installation height can be adjusted freely according to the length of the line tube. The line tube not only connects the lead-out line 1 The protection lead-out warehouse also plays the role of installing and fixing the electromagnetic knocking type object detection device. The magnetic knocking assembly is composed of a magnetic pendulum 5, a movable ring 9, a fixed hanging hole 8, a bracket 7, etc., and the brac...

Embodiment 2

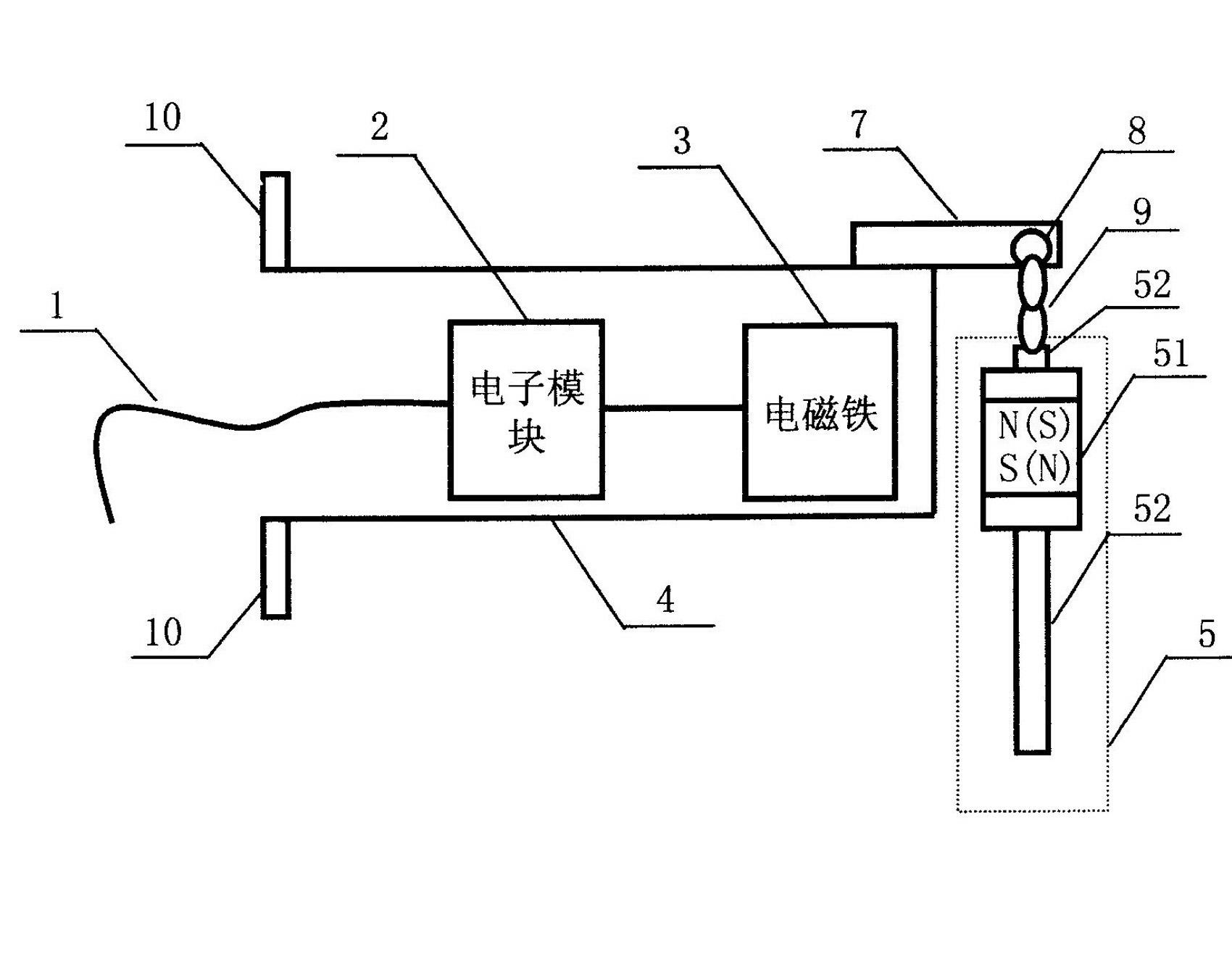

[0036] exist figure 1 , image 3 , Figure 8 Among them, the electromagnetic deliberation type object detection device is a side-mounted type, one end of the shell 4 is connected to the magnetic percussion assembly, and the other end is provided with a mounting flange 10 for directly fixing the electromagnetic deduction type object detection device on the warehouse board 12 , or fixed on the flange 14 of the installation sleeve, and the outlet hole is set on the installation flange 10, and other structural connection methods are the same as in the embodiment.

Embodiment 3

[0038] This embodiment belongs to the high temperature and high pressure type electromagnetic deliberation type object detection device. The electromagnet coil 32 in the electromagnetic deduction type object detection device of Embodiment 1 and Example 2 all adopts high temperature resistant electromagnetic wires, such as H grade electromagnetic wires with a temperature resistance of 180 degrees. , Class C electromagnetic wire can withstand a temperature of 220 degrees, Teflon insulated electromagnetic wire can withstand a temperature of 260 degrees, and a ceramic insulated electromagnetic wire can withstand a temperature of 500 degrees. High temperature resistant magnets such as boron, samarium cobalt, alnico, place the electromagnet 3 and the magnetic pendulum 5 in the high temperature place in the warehouse like this, place the electronic module 2 that is not resistant to high temperature in the normal temperature place, the electronic module 2 and the electromagnetic The ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com