Device for checking insufficient solder and cold solder of storage battery

An inspection device and storage battery technology, which is applied in the direction of optical testing for flaws/defects, etc., can solve problems such as insufficient battery capacity, unsatisfactory inspection results, and inconvenient operation, and achieve the effects of simple structure, easy operation, and accurate inspection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

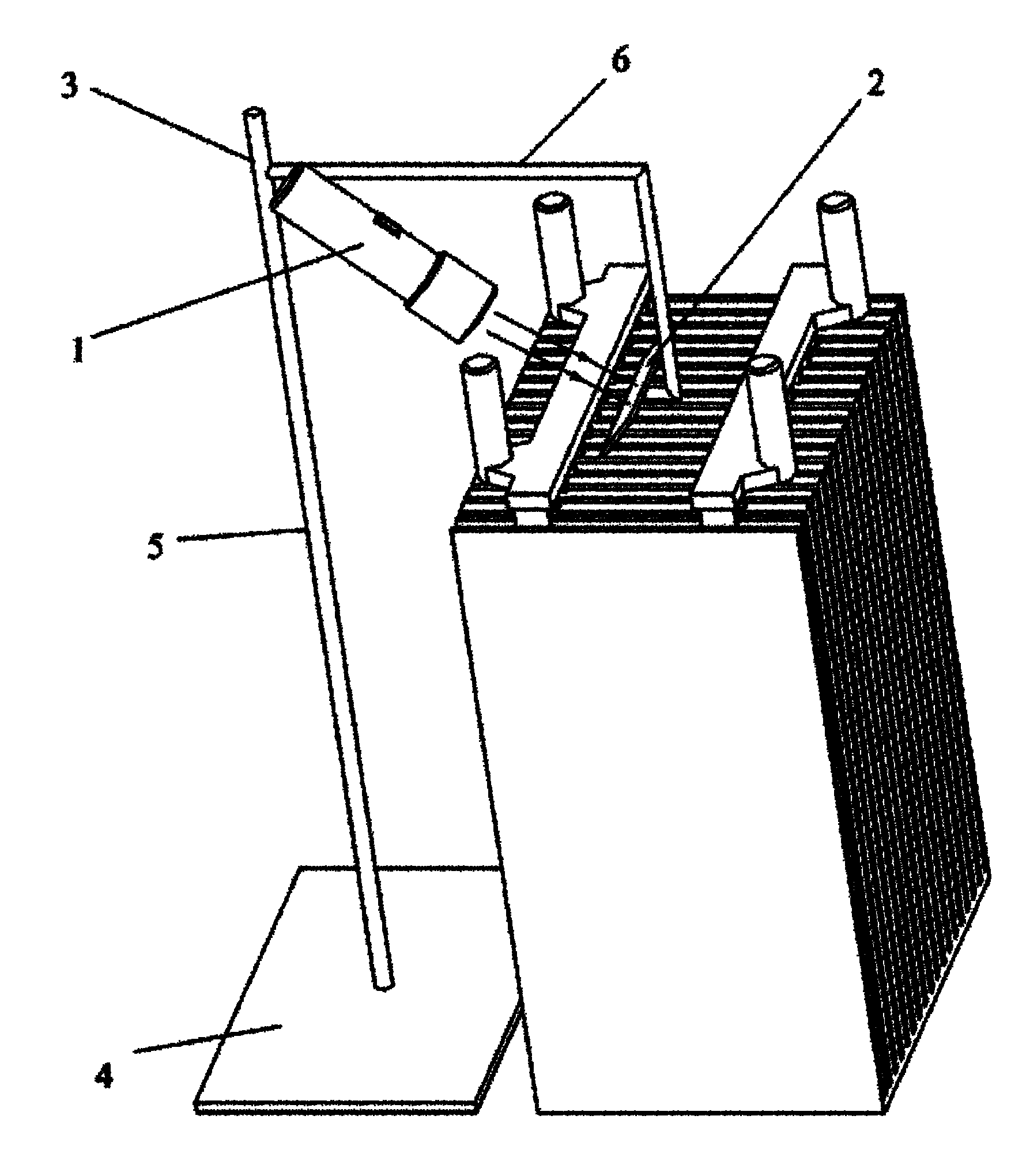

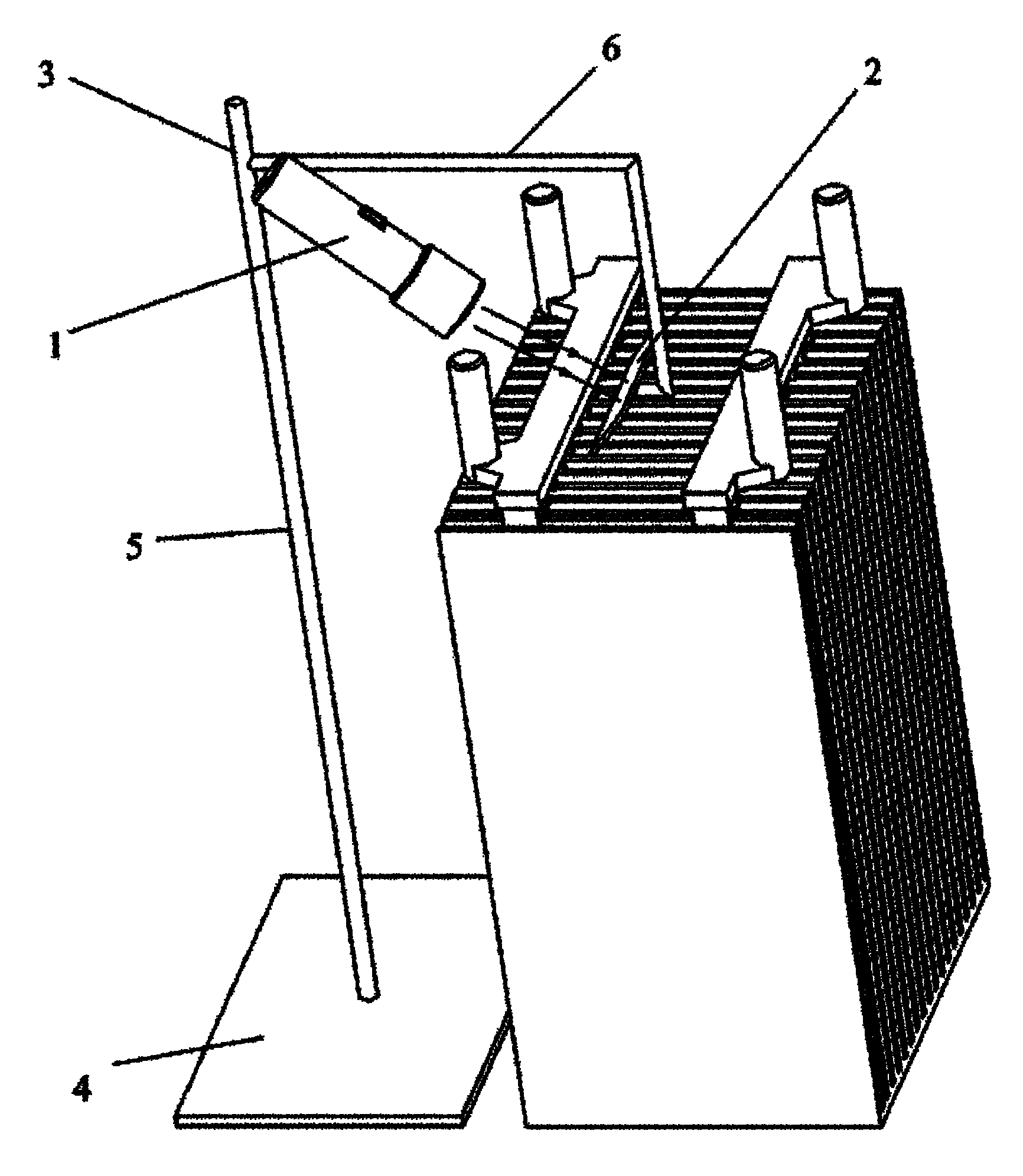

[0013] see figure 1 as shown, figure 1 It is a structural schematic diagram of a device for inspecting battery false welding and false welding, including a light source 1 , a refractor 2 and a bracket 3 , and the refractor 2 is fixed on the bracket 3 . The light from the light source 1 is refracted by the refractor 2 and irradiated on the battery bus bar of the battery, which can conveniently check the welding quality between the bottom of the battery bus bar and the tabs.

[0014] Further, the bracket 3 includes a base 4 , a support rod 5 and a fixing rod 6 . The refractor 2 is fixed on the fixed rod 6 movably. For the sake of simplicity, the refractor 2 can use a commonly used plane mirror, which is set at a certain angle between the plane mir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com