Repairing circuit for displaying panel

A display panel and liquid crystal display panel technology, applied in static indicators, nonlinear optics, instruments, etc., can solve problems such as increased defect rate, and achieve the effect of avoiding insufficient charging and reducing panel scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

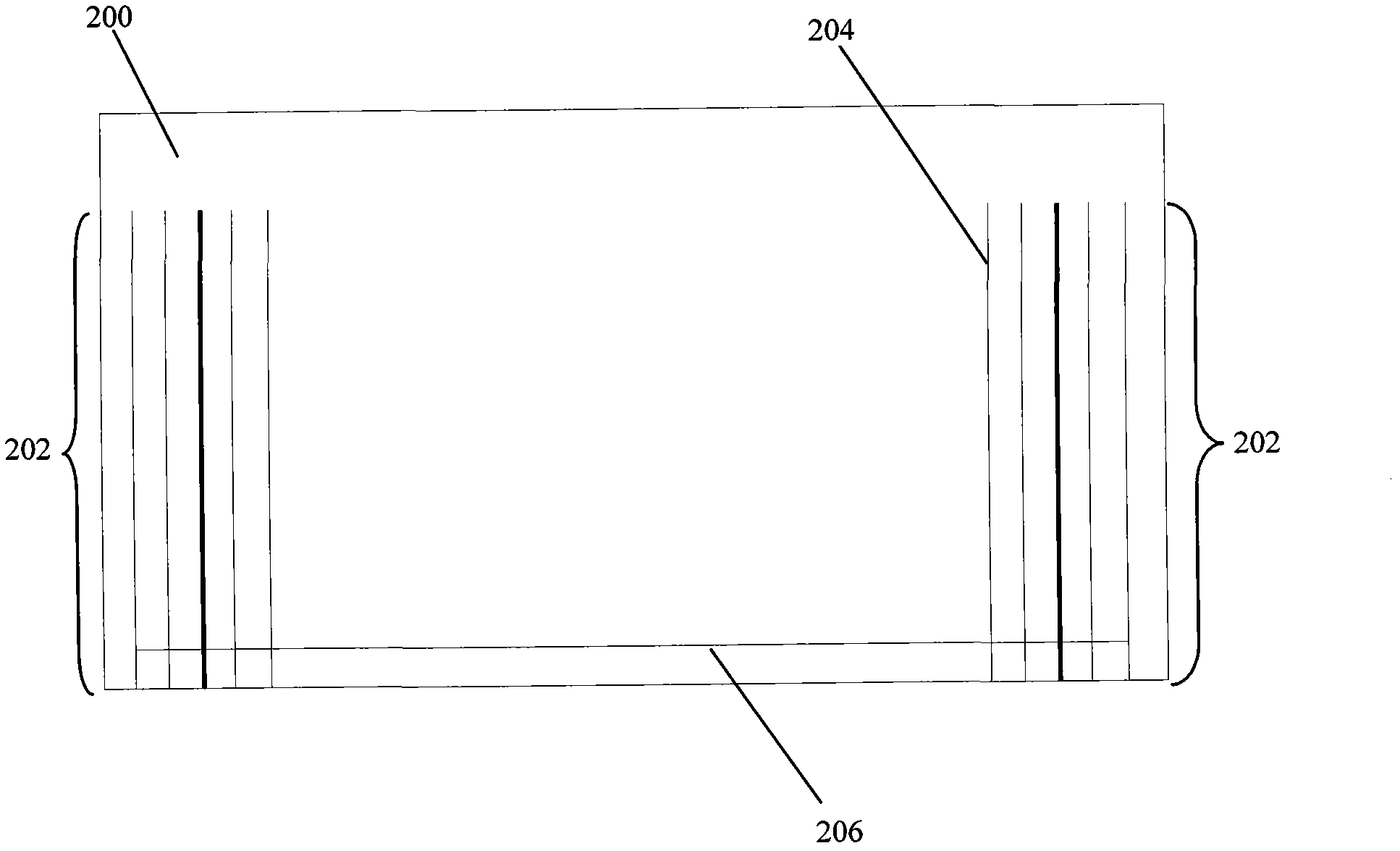

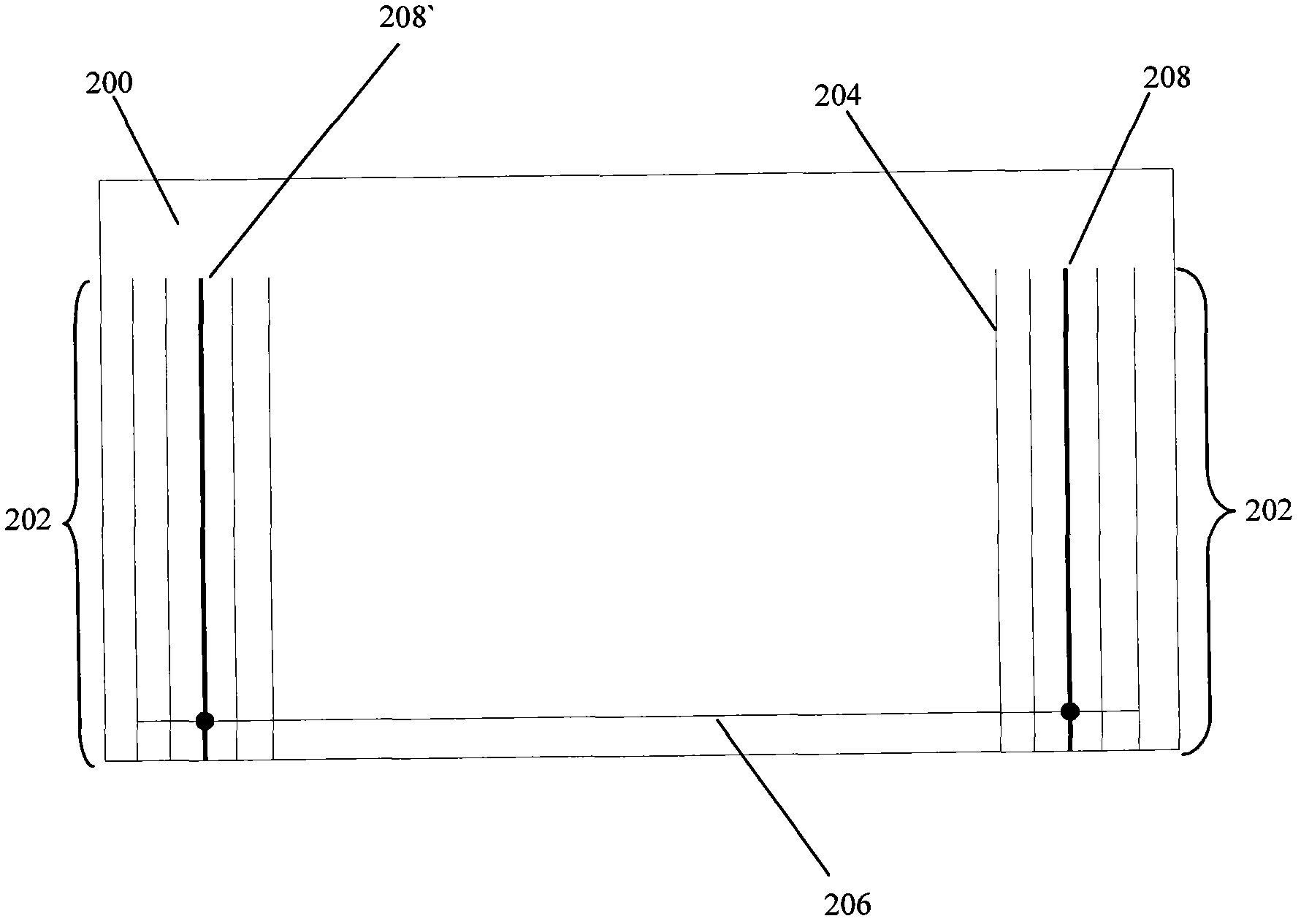

[0017] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings. Throughout the description, like reference numerals refer to like parts. It should be understood that in the drawings of this application, the "solid lines" and "dotted lines" used to electrically connect a certain component with another component are only for the convenience of describing specific embodiments of the present invention, and are not intended to induce It will be understood by those skilled in the art that solid lines indicate electrical connection and dashed lines indicate electrical isolation. Any person skilled in the art, after understanding the preferred embodiments of the present invention, can make changes and modifications based on the technology disclosed in the present invention without departing from the spirit and scope of the present invention.

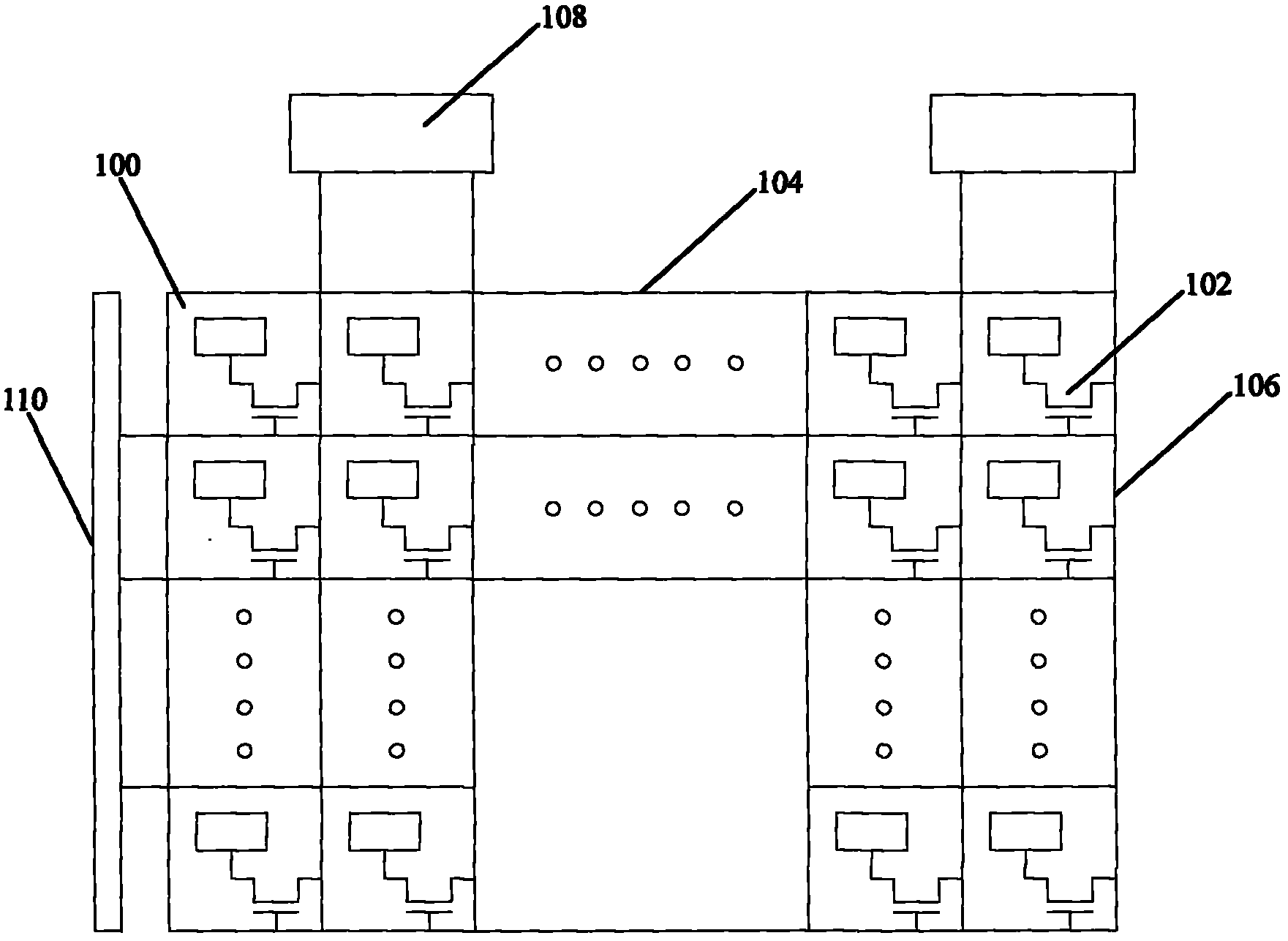

[0018] refer to figure 1 , which is a schematic ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com