Mechanical optical gate of high-power laser

A laser and high-power technology, applied in the field of lasers, can solve the problems of unstable mechanical shutter guidance, low primary heat exchange efficiency, large movement displacement deviation, etc., to achieve light weight, reduce rigid impact, and reduce frictional resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

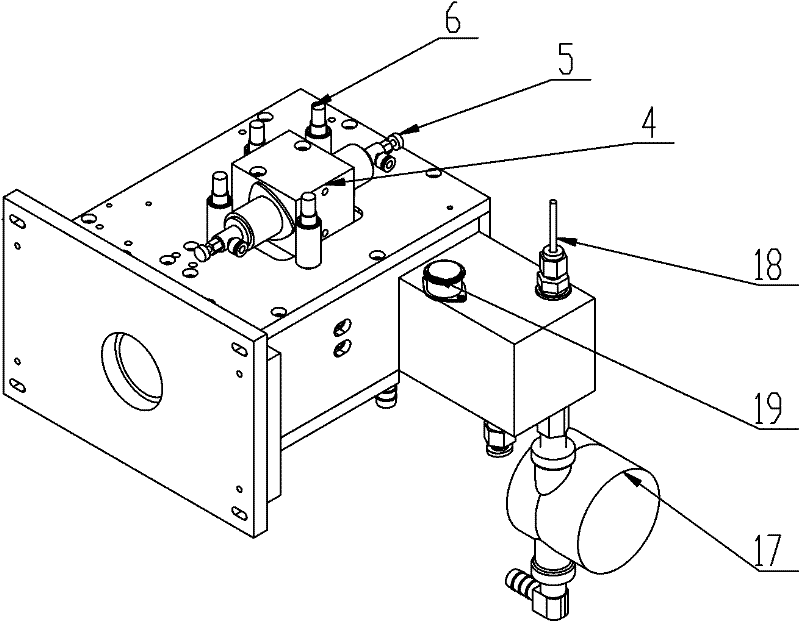

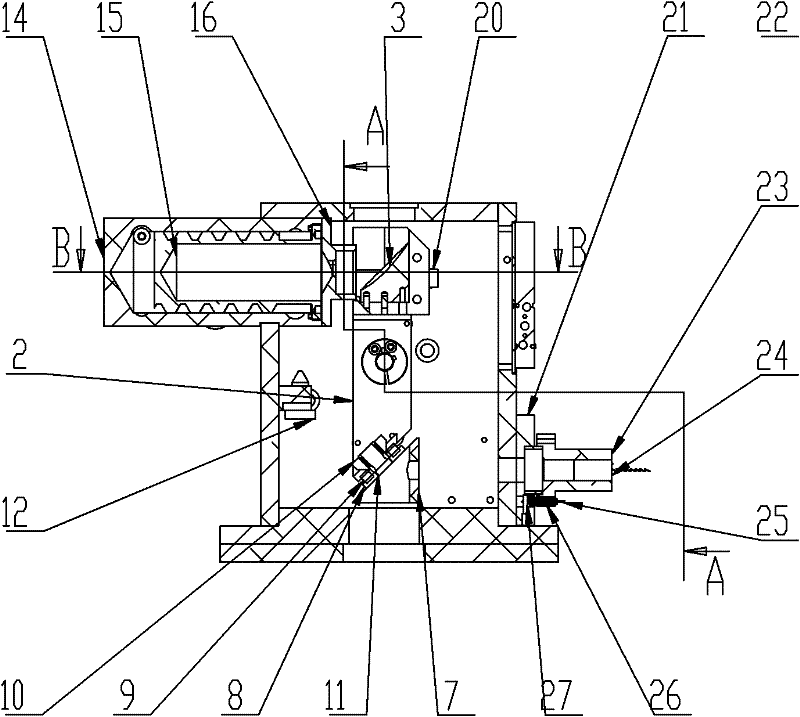

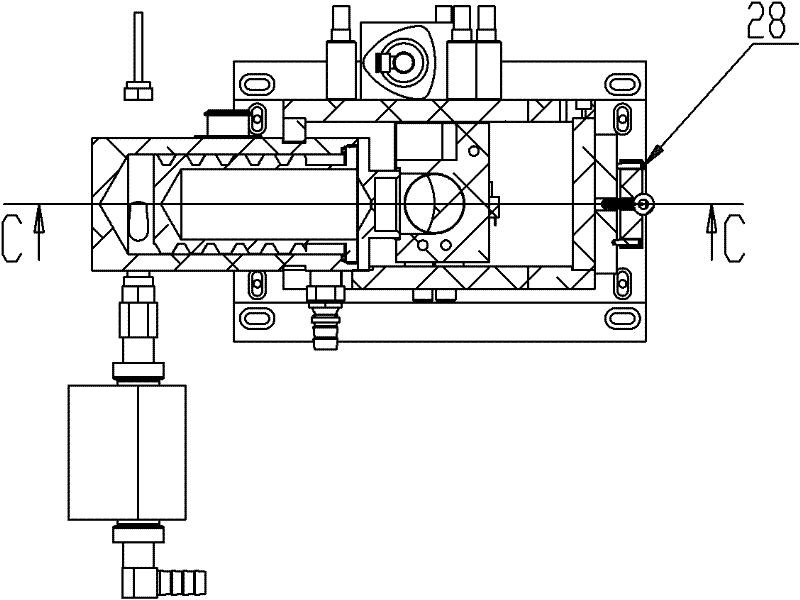

[0030] Such as Figure 1-10 The mechanical shutter of the high-power laser shown includes a feed mechanism, a guide mechanism and an energy absorption mechanism. The guide mechanism includes a shutter box 1, and a shutter rotating body 2 is installed in the shutter box 1. The shutter box A semiconductor red light generator 24 is installed on one side, a red light reflector 11 on the same horizontal line as the center of the semiconductor red light generator 24 is installed at the front end of the shutter rotating body 2, and a shutter mirror 3 is installed at the tail end ; The feed mechanism includes a rotating cylinder 4 connected to the rotating shaft in the middle of the shutter rotating body 2; As well as the absorber core 15 absorbing energy in the absorber housing 14 , the absorber aperture 16 is provided with an oblong opening corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com