Primary winding of a cylindrical asynchronous linear motor

A primary winding, linear motor technology, applied in the direction of electric components, shape/style/structure of winding conductors, electrical components, etc., can solve the problems of discontinuous traveling wave magnetic field, a lot of wiring work, increase joint resistance, etc., to achieve good mechanical and electrical dielectric strength, reducing overall resistivity, reducing complexity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

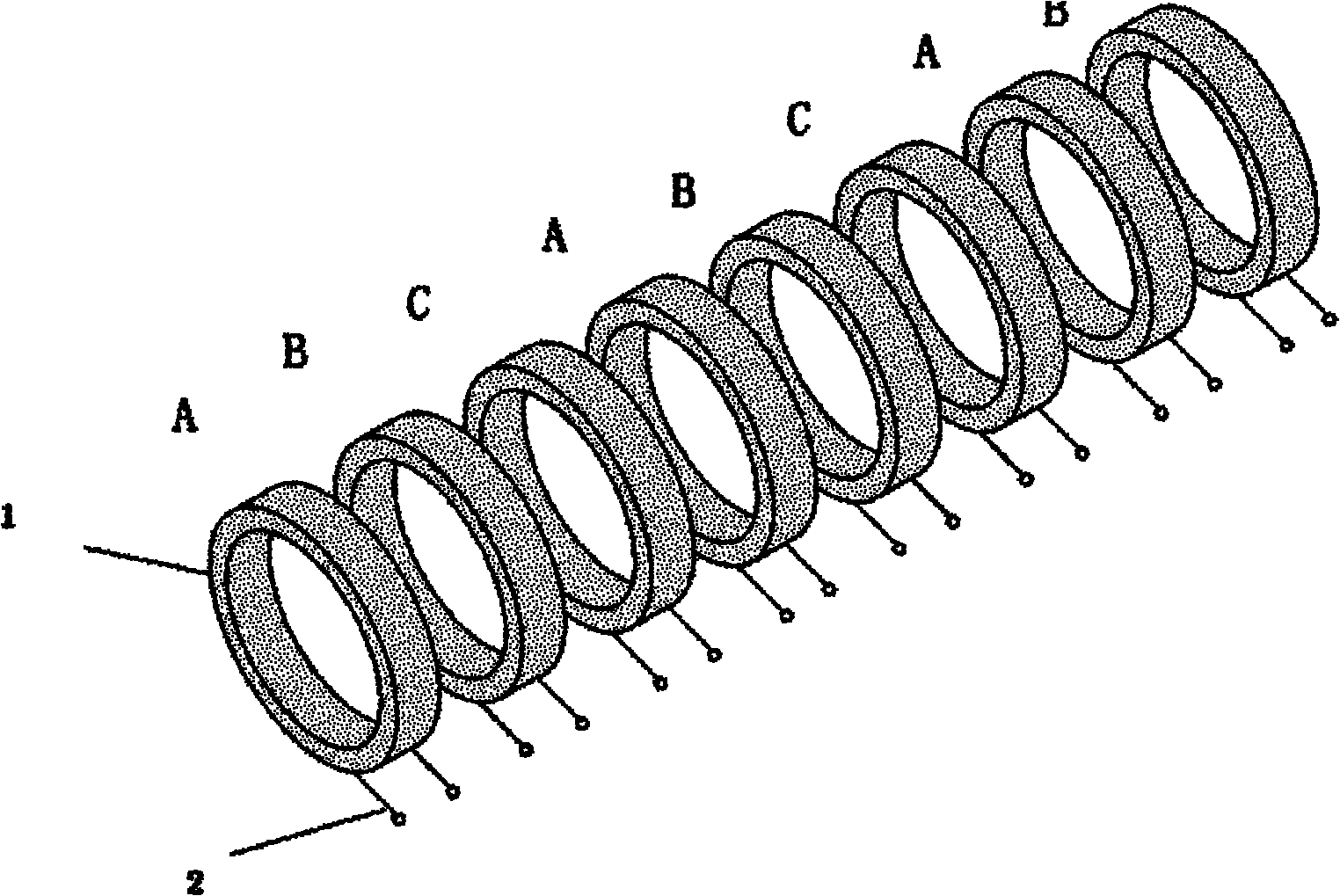

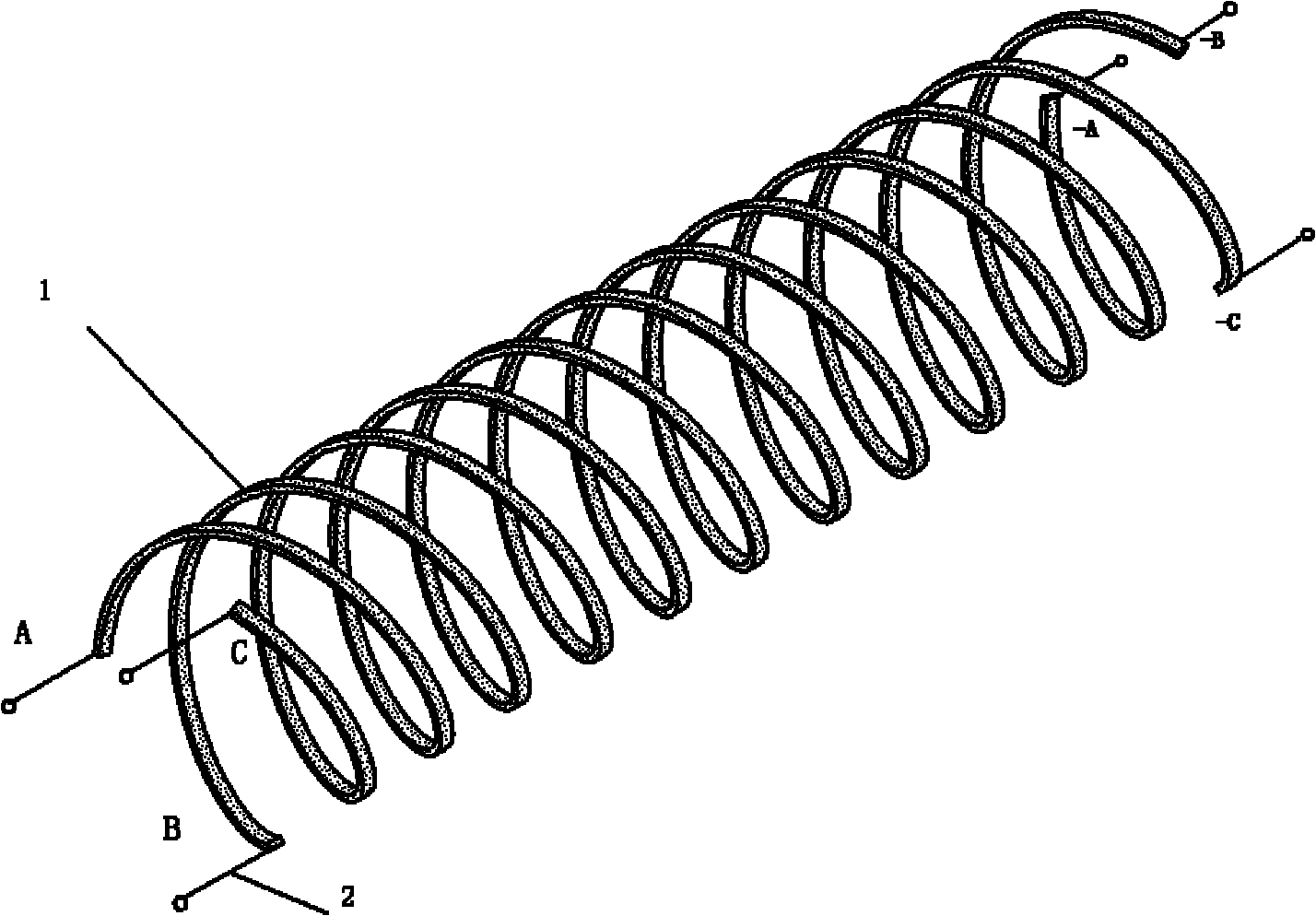

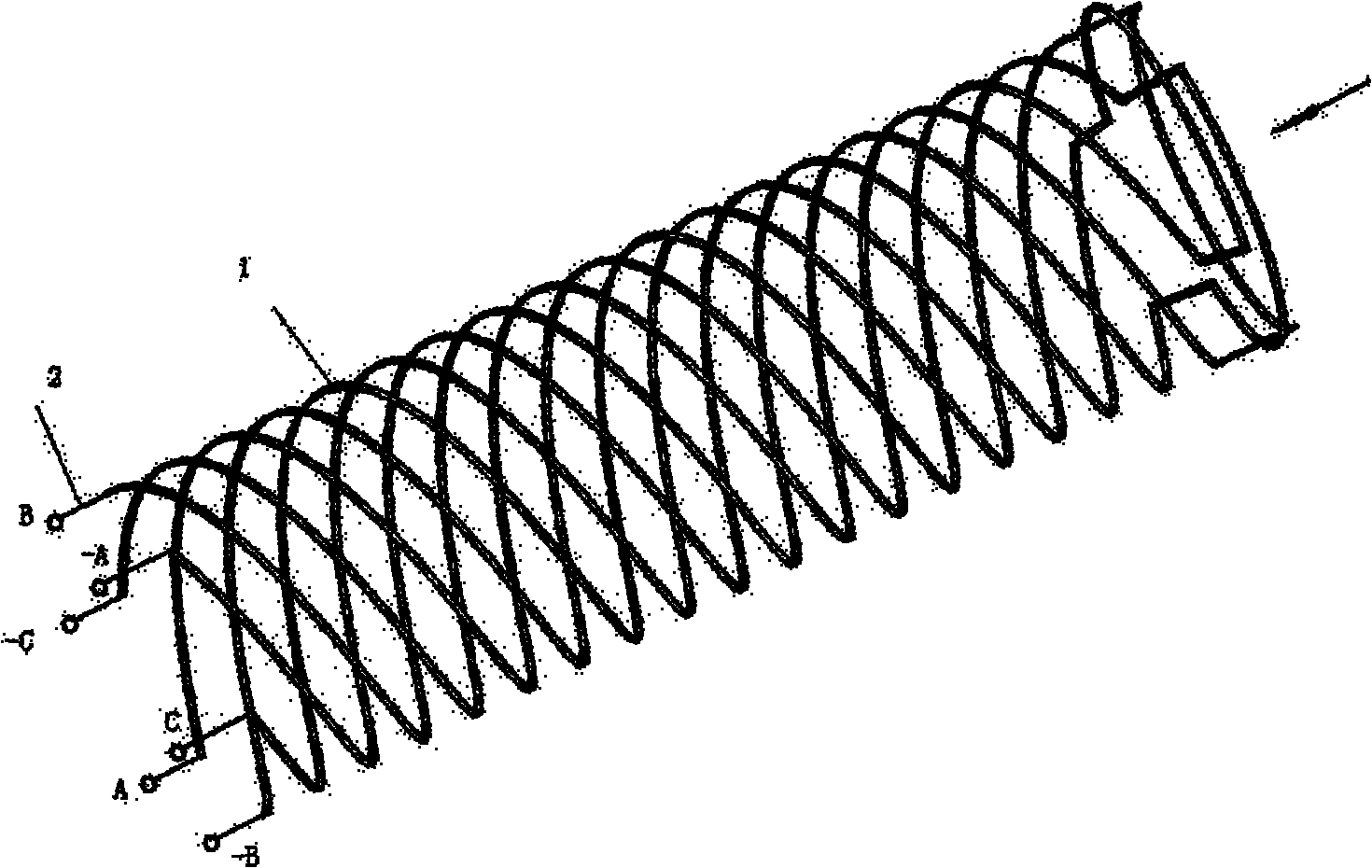

[0016] Such as figure 2 The primary of the cylindrical asynchronous straight line shown in the present invention, the ABC three-phase wires are continuously spirally wound at 120° in the circumferential direction to form a winding 1, and its lead wire 2 can be as follows: figure 2 shown distributed at both ends of the winding, it can also be as image 3 As shown, one end of the winding goes out, which is called the outlet end, corresponding to the A, B, and C three-phase leads at the inlet end, and the leads at the outlet end can be called -A, -B, and -C, respectively. The other end of the winding, which may be referred to as a blind end, such as Figure 4 As shown, at the blind end, the three-phase wires are respectively transposed 180° apart in the circumferential direction and wound back in the same helical direction. ° Corresponding re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com