Suspension frame of medium-low speed magnetic levitation vehicle

A suspension frame and maglev technology, applied to railway vehicles, vehicle parts, motor vehicles, etc., can solve the problems of insufficient suspension stability and large static assembly deformation of suspension frames, etc., and achieve simple and reliable structure, easy disassembly and assembly, and overall layout concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

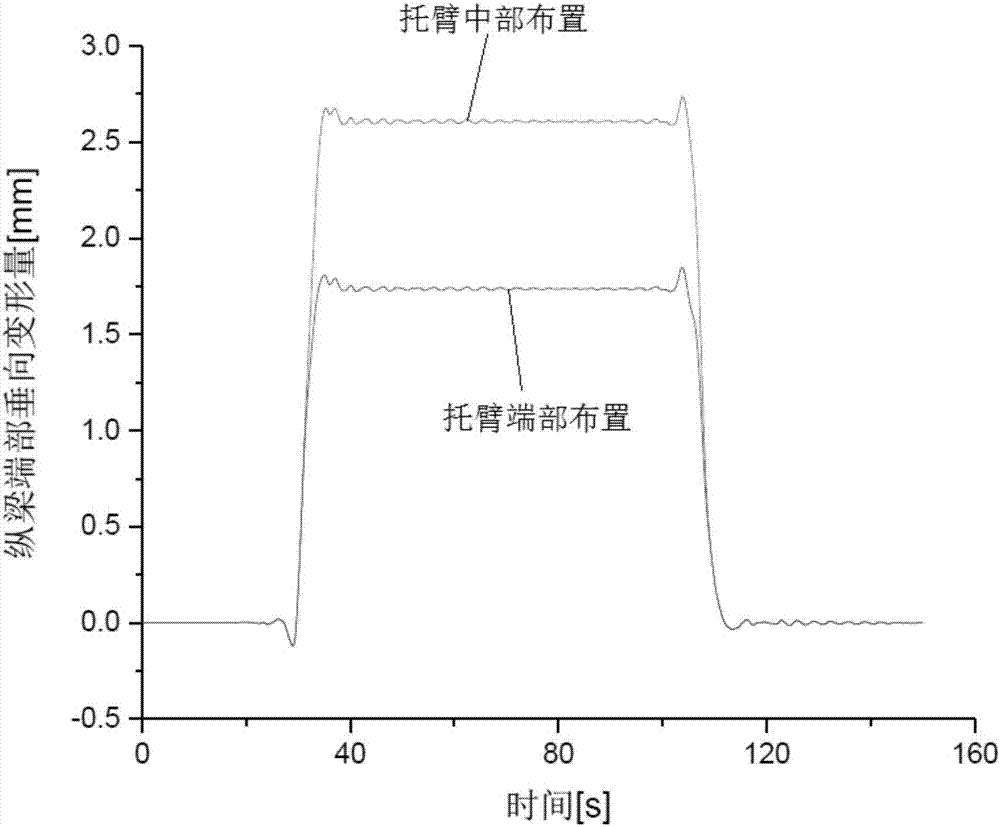

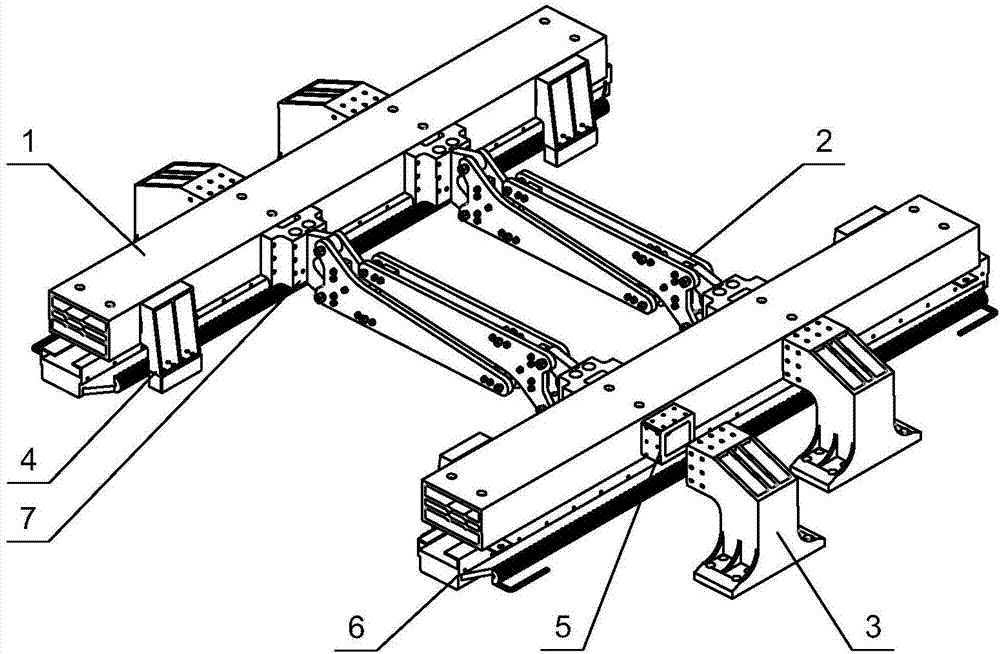

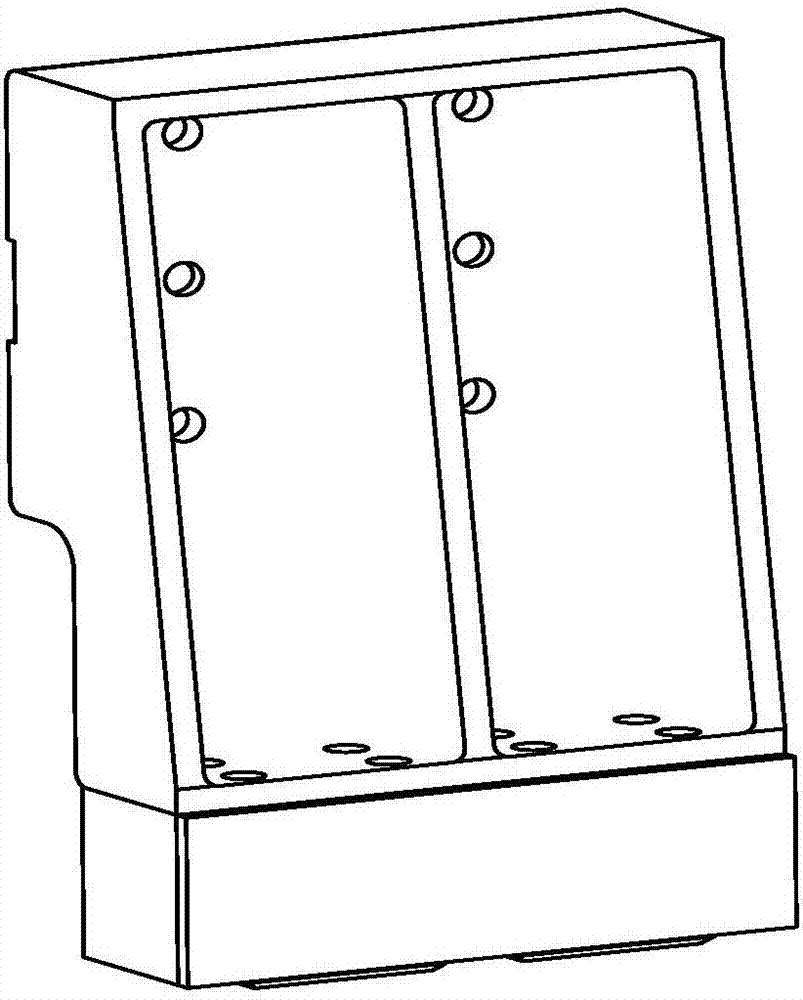

[0015] like figure 1 As shown, the middle-mounted support arm suspension frame for medium and low-speed maglev vehicles mainly includes two longitudinal beams 1 arranged on the left and right, two sets of anti-roll beam assemblies 2, four support arms 3 and four vertical skids 4 and other components. The suspension frame for medium and low-speed maglev vehicles with mid-mounted brackets includes left and right longitudinal beams 1 and anti-roll beam components 2, and a set of anti-roll beam mounting seats 7 are respectively provided on both sides of the vertical center line inside the longitudinal beam 1 , the anti-roll beam assembly 2 is connected to the longitudinal beam 1 through the mounting seat 7 to form a suspension frame, and the linear motor 6 is located below the longitudinal beam 1 . The outer surface of the longitudinal beam 1 and the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com