Strong aromatic white spirit trans-production method

The technology of a strong-flavor liquor and a production method, which is applied in the field of winemaking, can solve the problems of high cost, waste of grain, and affect the fermentation effect, etc., and achieve the effects of improving quality, reducing consumption and waste, and improving the quality of wine body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

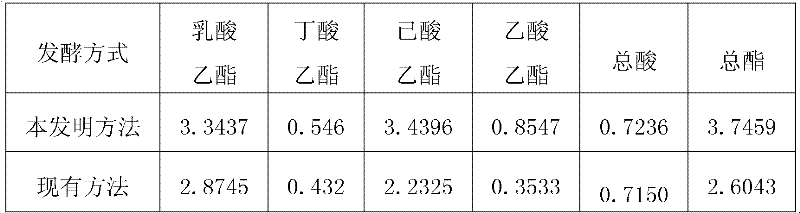

[0031] Embodiment Using the method of the present invention to transpose to produce Luzhou-flavor liquor

[0032] Distiller's grains out of the cellar, no grain input, every 2.4m 3 Distiller's grains are put into 21kg of bran shells, distilled, cooled to ambient temperature (25-35°C), and then every 2.4m 3 36kg of warm koji medicine in distiller's grains mixing is put into the cellar, and the distiller's grains are manually stepped on to reduce the air content in the cellar, and the cellar is sealed for fermentation.

[0033] Open the cellar after 1 month of fermentation, take out all the distiller's grains, every 2.4m 3 Distiller's grains are put into 22kg of ultra-high temperature Daqu and mixed evenly.

[0034] Re-enter the cellar, step on the distiller's grains manually, and seal the cellar for fermentation.

[0035] After 1 month of fermentation, open the cellar, every 2.4m 3 The distiller's grains are poured into 24kg of wine head and wine tail mixed liquor (equivale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com