Method for improving quality of wine produced from increased distilled grains

A technology for growing wine and distiller's grains, applied in the field of wine making, can solve the problems of heavy wine body, low cellar temperature, low starch content, etc., achieve the effect of improving the quality of wine body and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

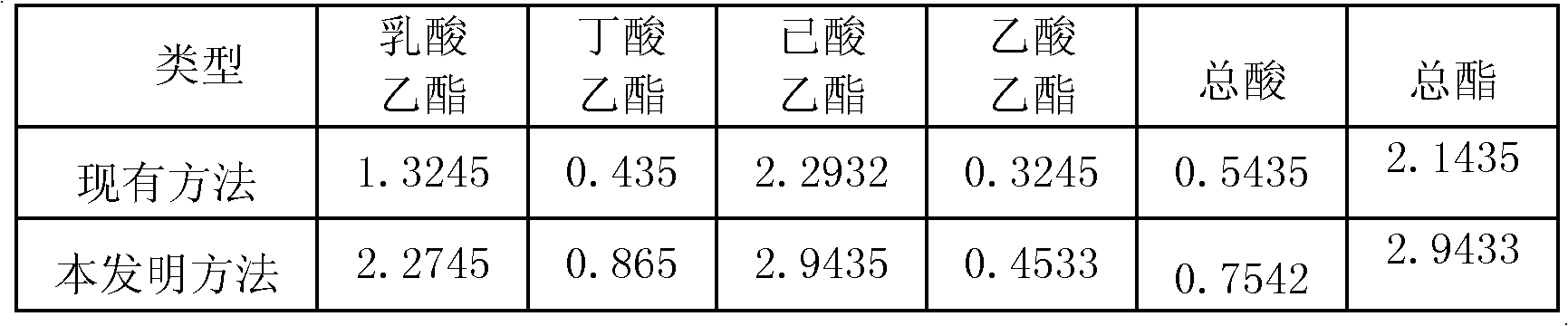

Image

Examples

Embodiment Construction

[0016] The method for improving the quality of distiller's grains produced by the present invention comprises the following steps:

[0017] a, increase the distiller's grains steamed wine (according to the conventional process, steamer steamed wine), increase the distiller's grains steamed wine, control the water content of the distiller's grains after steaming, so that the water content of the distiller's grains when entering the cellar for fermentation is 50 ~ 53wt% (distiller's grains moisture When the content of distiller's grains is too high, distiller's grains with low water content can be added. When the water content of distiller's grains is insufficient, it can be supplemented by pumping water. If the water content of distiller's grains is too small, the growth of fermentation aroma microorganisms will be inhibited due to insufficient water, and the water content of distiller's grains will be reduced. If the content is too large, it is easy to produce yellow water, wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com