Vibration-less compaction method of collapsible loess foundation

A technology for collapsible loess and treatment methods, which is applied in the field of non-vibration compaction treatment of collapsible loess foundations, can solve problems such as tunnel cracking, block falling, and environmental pollution, and achieve the effect of improving bearing capacity and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

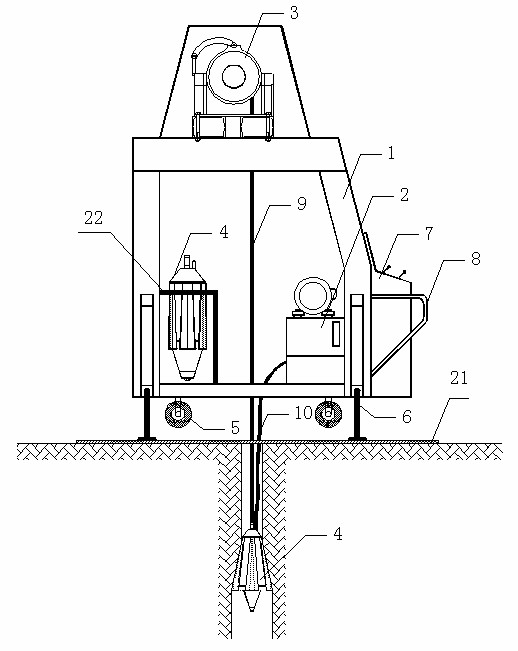

[0017] 1. Non-vibration compaction reaming equipment

[0018] see figure 1 , a hydraulic device 2 is arranged on the frame 1, a hydraulic winch 3 is arranged on the top of the frame, and a hydraulic support leg 6 is arranged on the bottom of the frame 1; the hydraulic winch 3 is connected with a compacting reaming device 4 through a wire rope 9; The compacting and reaming device 4 is connected with the hydraulic device 2 through a high-pressure oil pipe 10 .

[0019] Frame 1 is a platform for installing various components, which is welded by steel structure.

[0020] The hydraulic device 2 is installed on the lower part of the frame 1 through bolts, and is mainly composed of a hydraulic oil tank, a hydraulic pump, an electric motor, and a control valve to drive the hydraulic outrigger 6, the hydraulic winch 3 and the compacting and reaming device 4 to work normally.

[0021] The hydraulic winch 3 is installed on the top of the frame 1 through high-strength bolts. Driven by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com