A construction method for strengthening and treating karst foundation of new railways and its subgrade structure

A construction method and karst technology, applied in infrastructure engineering, roads, buildings, etc., can solve the problems of not being popularized and used on a large scale, being uneconomical, and not being able to control post-construction settlement well, so as to achieve foundation reinforcement structure form and construction The process is not complicated, the effect of improving the bearing capacity of the foundation and reducing the uneven settlement of the foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

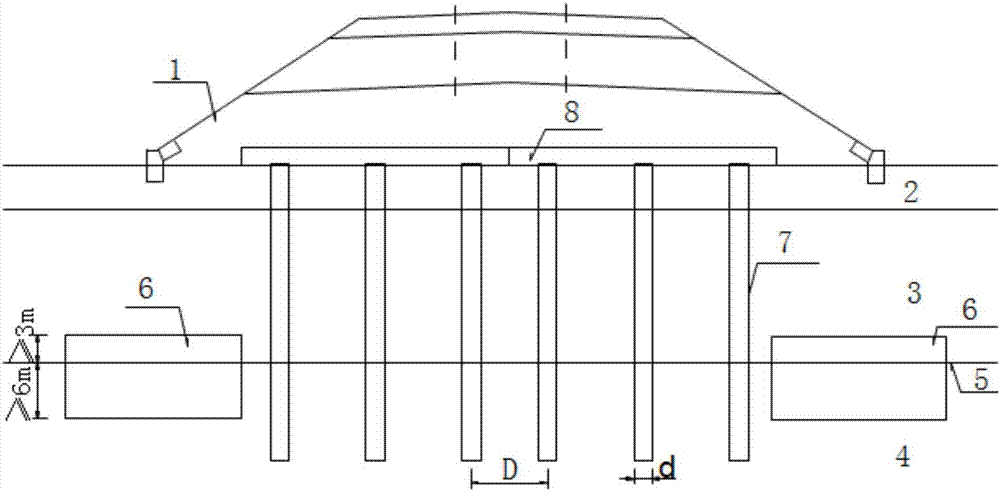

[0028] Such as figure 1 As shown, the present invention provides a subgrade structure for strengthening and treating the karst foundation of a new railway, where the karst foundation structure includes a karst layer 4, a hard soil layer 3 above the karst layer 4, and a soft soil layer 2 above the hard soil layer 3 , the subgrade structure includes a slab girder 8 arranged on the top of the soft soil layer 2, a subgrade 1 laid on the top of the slab girder 8, the slab girder 8 is arranged longitudinally along the line and symmetrically arranged laterally with the center line of the line, and the center line of the line is the center line of the subgrade, The transverse ends of the plate girder 8 are respectively located between the road shoulder and the toe of the same side of the subgrade 1 (such as the left lateral end of the plate g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com