A gas fluid mixture self-priming pump

A gas-liquid mixed transport and self-priming pump technology, applied in the field of hydraulic machinery, can solve the problems of small displacement, unfavorable energy saving, complicated operation, etc., and achieve the effects of strong self-priming ability, improved service life, and convenient installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

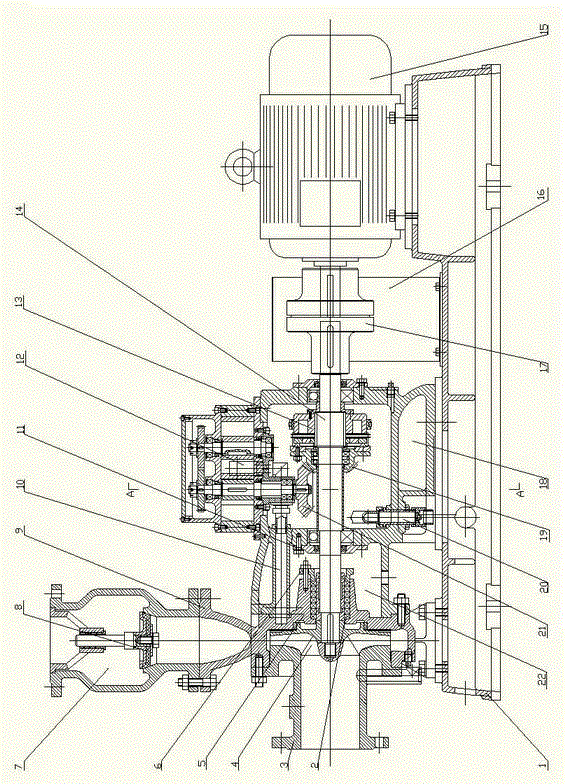

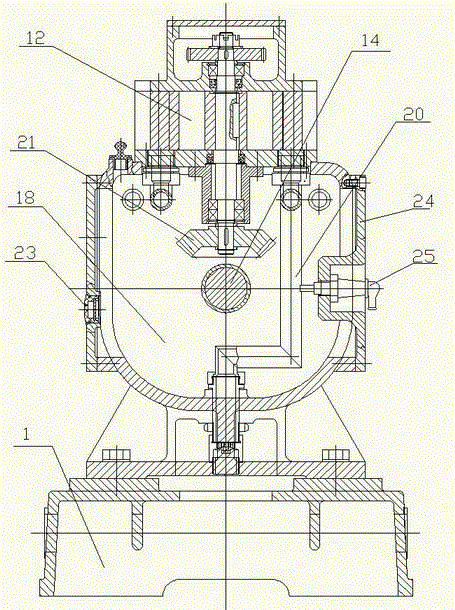

[0019] The present invention comprises Roots pump 12, motor 15, is characterized in that: the shaft of motor 15 is connected with rotor 14 through coupling 17;

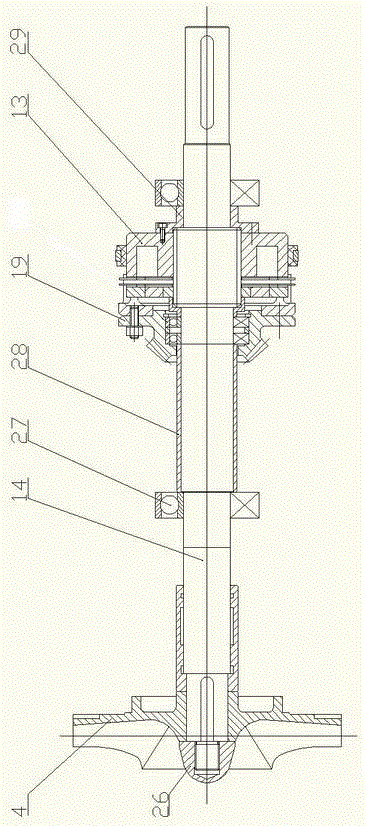

[0020] The rotor 14 passes through the spindle box 18 and the mechanical seal chamber 22, and extends to the inlet section 3, and the rotor 14 is installed with the impeller 4 through the impeller nut 26 at the end of the inlet section 3;

[0021] The rotor 14 is connected to the shell of the main shaft box 18 through bearings, and is sealed by the bearing cover 11. A Roots pump 12 is installed in the main shaft box 18, and a driven bevel gear 21 is installed on the shaft of the Roots pump 12. On the rotor 14 Clutch 13 is installed on it, and driving bevel gear 19 is installed on the front end of clutch 13, and driving bevel gear 19 meshes with driven bevel gear 21;

[0022] The inlet of the Roots pump 12 is connected to the suction pipe 10, the other end of the suction pipe 10 communicates with the inlet section 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com