Pressure induction type flow switch

A flow switch and inductive technology, which is applied in the field of flow measurement devices, can solve problems such as difficult detection, drop-shaped flow leakage, and inability to detect, and achieve the effects of convenient maintenance and use, reduced equipment costs, and accurate and reliable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

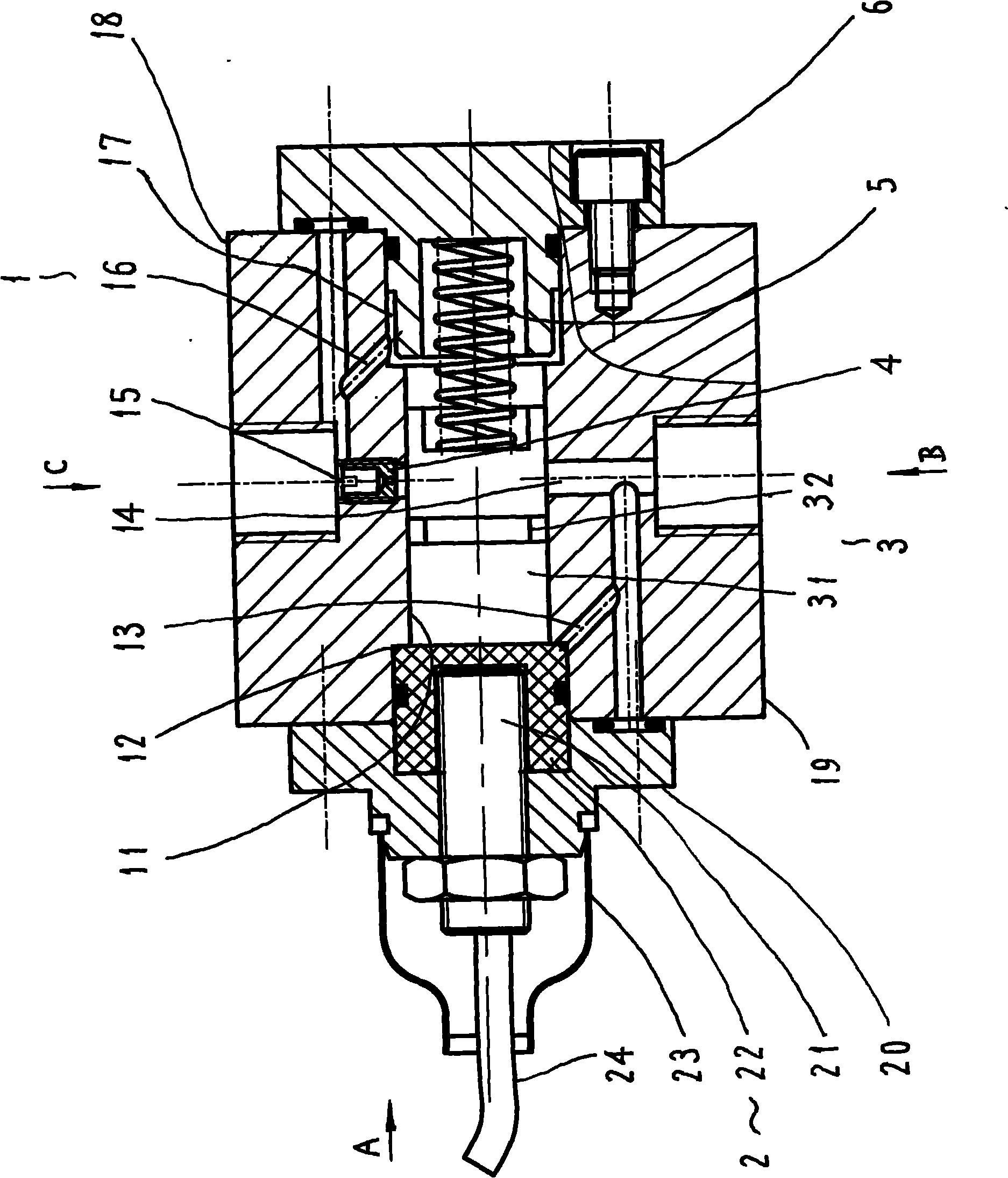

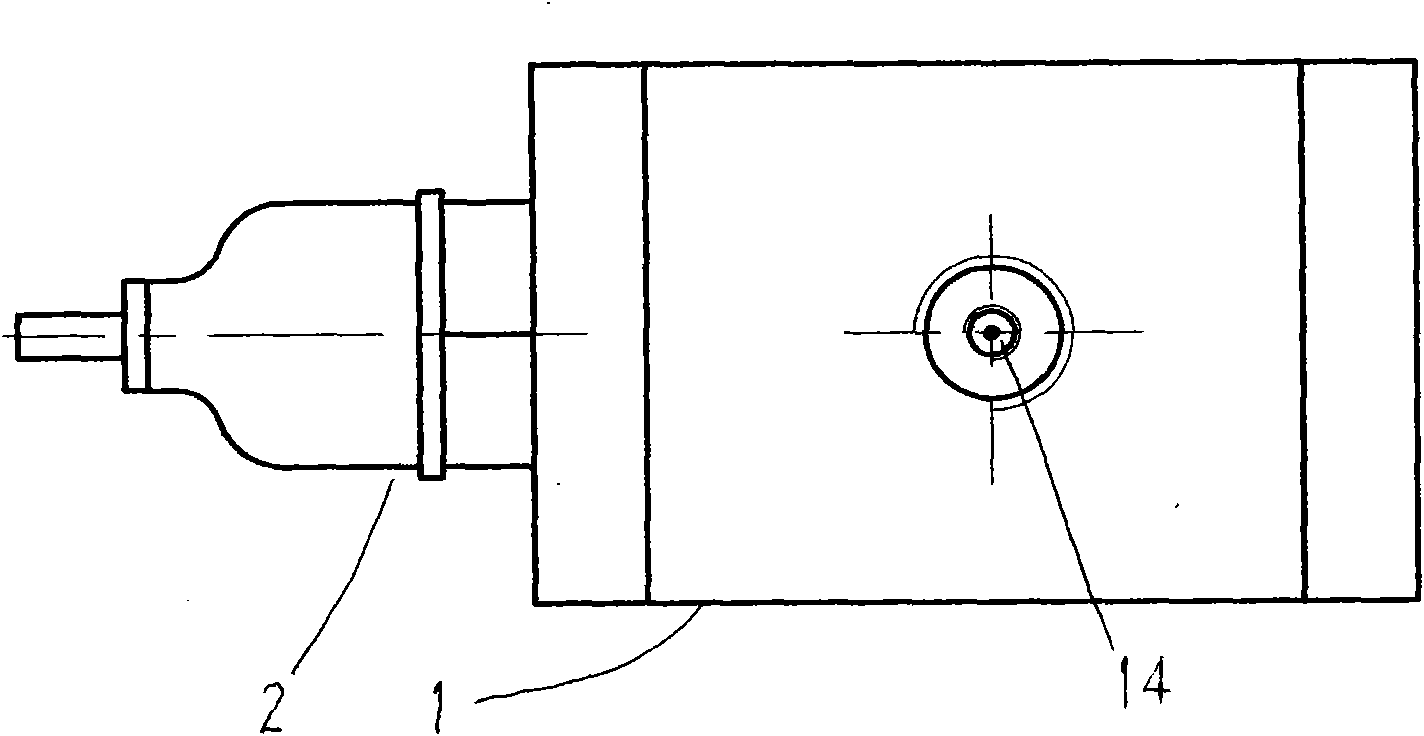

[0016] refer to figure 1 , The pressure-sensing flow switch includes a switch body 1, a proximity switch assembly 2, a sensing piston 3, a damper 4, a spring 5 and a right end cover 6.

[0017] The switch body 1 is a block, part of which has a working chamber 11 in the longitudinal direction. The working chamber 11 is a round hole for accommodating the sensing piston 3. The surface of the round hole is finely processed to ensure that the sensing piston 3 can move freely. Move to form a sliding fit, and can ensure good sealing between the mating surfaces of the two; the working chamber 11 and other related parts of the configuration together form a sealed working chamber;

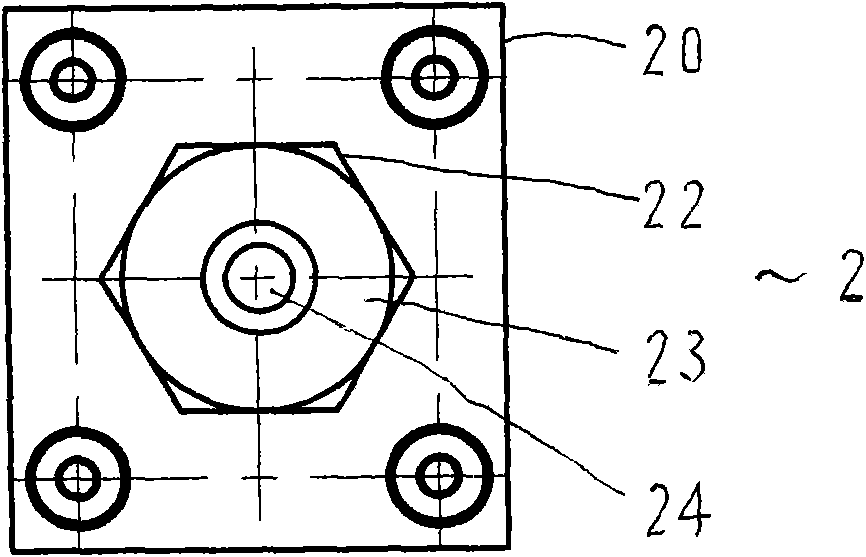

[0018] The left chamber 12 in the switch body 1 is a part of the left side of the working chamber 11, and is a sealed space jointly formed by the working chamber 11, the bottom surface of the left end cover 20 of the proximity switch assembly 2, the left end surface of the sensing piston 3 and the correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com