Control circuit of relay coil of electric vehicle

A technology of relay coils and electric vehicles, which is applied in the direction of relays, circuits, electrical components, etc., and can solve the problem of high requirements for relay operating parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

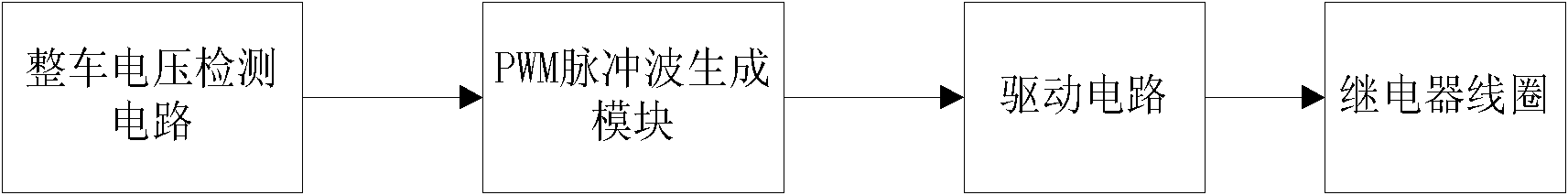

[0013] Such as image 3 As shown, the electric vehicle relay coil control circuit of the present invention includes a vehicle voltage detection circuit, a PWM pulse wave generation module, a drive circuit and a relay coil, the output of the vehicle voltage detection circuit is connected to the PWM pulse wave generation module, and the PWM pulse wave The output of the generation module pushes the relay coil through the drive circuit to control the opening and closing of the relay, wherein the PWM pulse wave generation module determines the relay coil current, impedance and withstand voltage according to the electromagnetic attraction on the side of the relay coil, according to the PI regulator and The anti-saturation regulator combines the vehicle voltage to obtain the PWM output frequency of the control side. Specifically, the average current power on the load is changed from 0-100% by changing the duty cycle of the output square wave, thereby changing the electromagnetic forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com