Rolling shaft type zipper puller

A zipper head and roller technology, applied in the field of zippers, can solve the problems of inconsistent specifications of zipper heads, not easy to use interchangeably, and short life of zippers, etc., and achieve the best sliding degree, prevent tooth explosion, and prolong the sliding degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

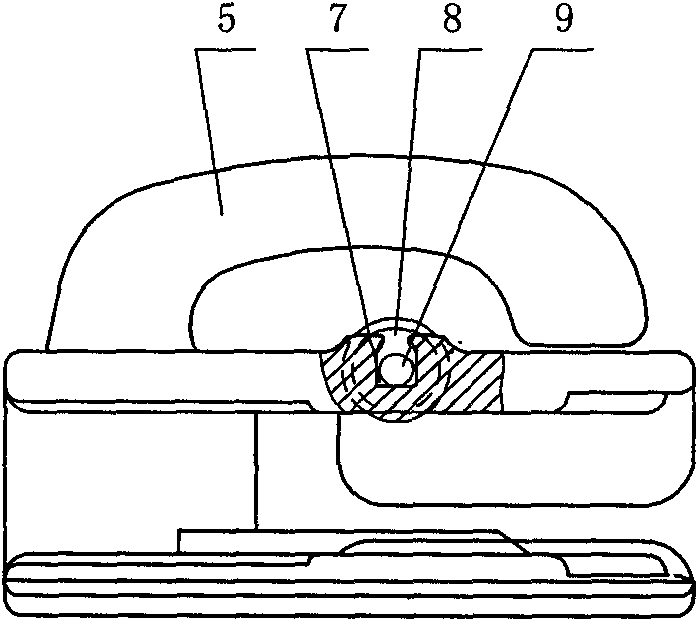

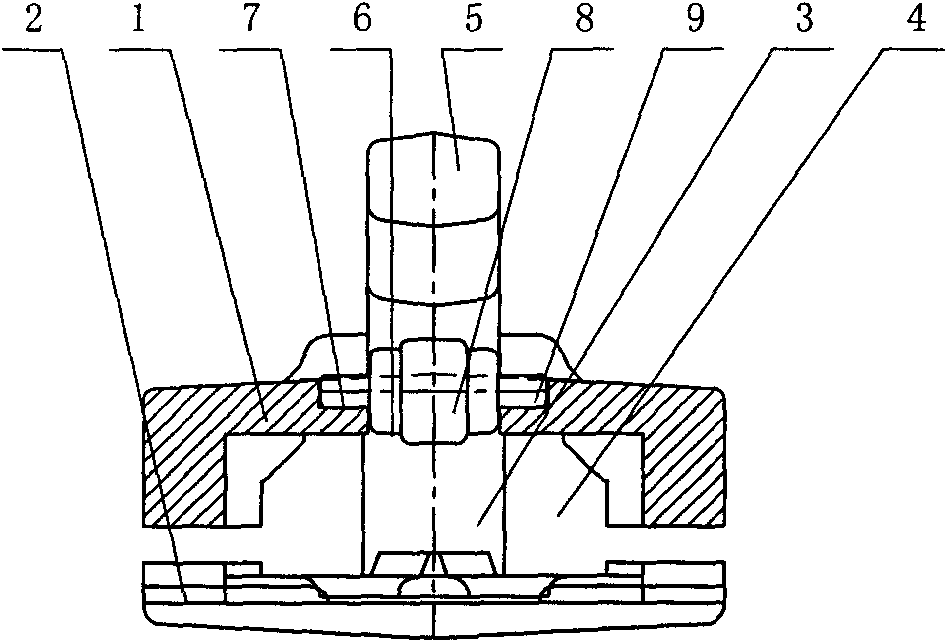

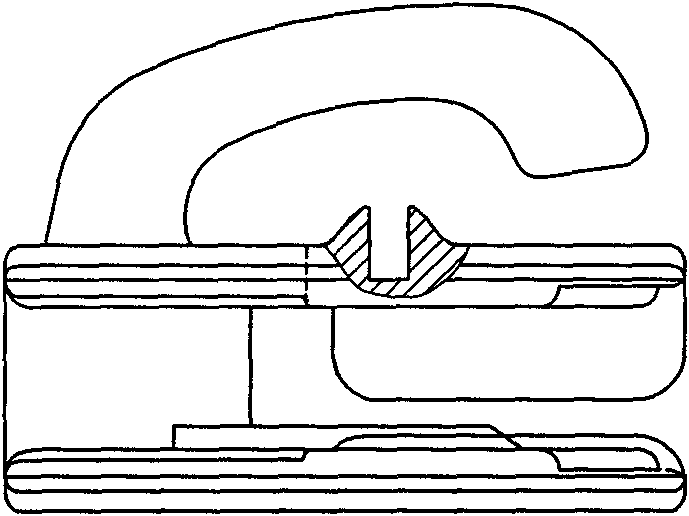

[0043] Roller zipper pulls such as figure 1 , figure 2 As shown, it includes an upper guard plate 1, a lower guard plate 2, and a guide base 3 connecting the upper guard plate 1 and the lower guard plate 2, and the upper guard plate 1 and the lower guard plate 2 form an inner In the space 4, a connection portion 5 for installing a pull tab is provided above the upper guard plate 1, a through groove 6 is provided near the middle of the upper guard plate 1, and opposite shafts are respectively provided on both sides of the through groove 6. Seat groove 7 such as image 3 As shown, the through groove 6 communicates downward with the internal space 4 of the zipper head, at least one roller 8 is arranged in the through groove 6 and the shaft seat groove 6 on both sides of the through groove 6, and the roller The lower surface of 8 slightly expos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com