Freely adjusted electromagnetic adsorption-type flexible bed-jig structure

An adsorption and electromagnetic technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as increased workload, increased risk of corrosion, damage, poor processing quality, etc., to increase equipment occupancy rate, improve equipment Utilization rate, effect of reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

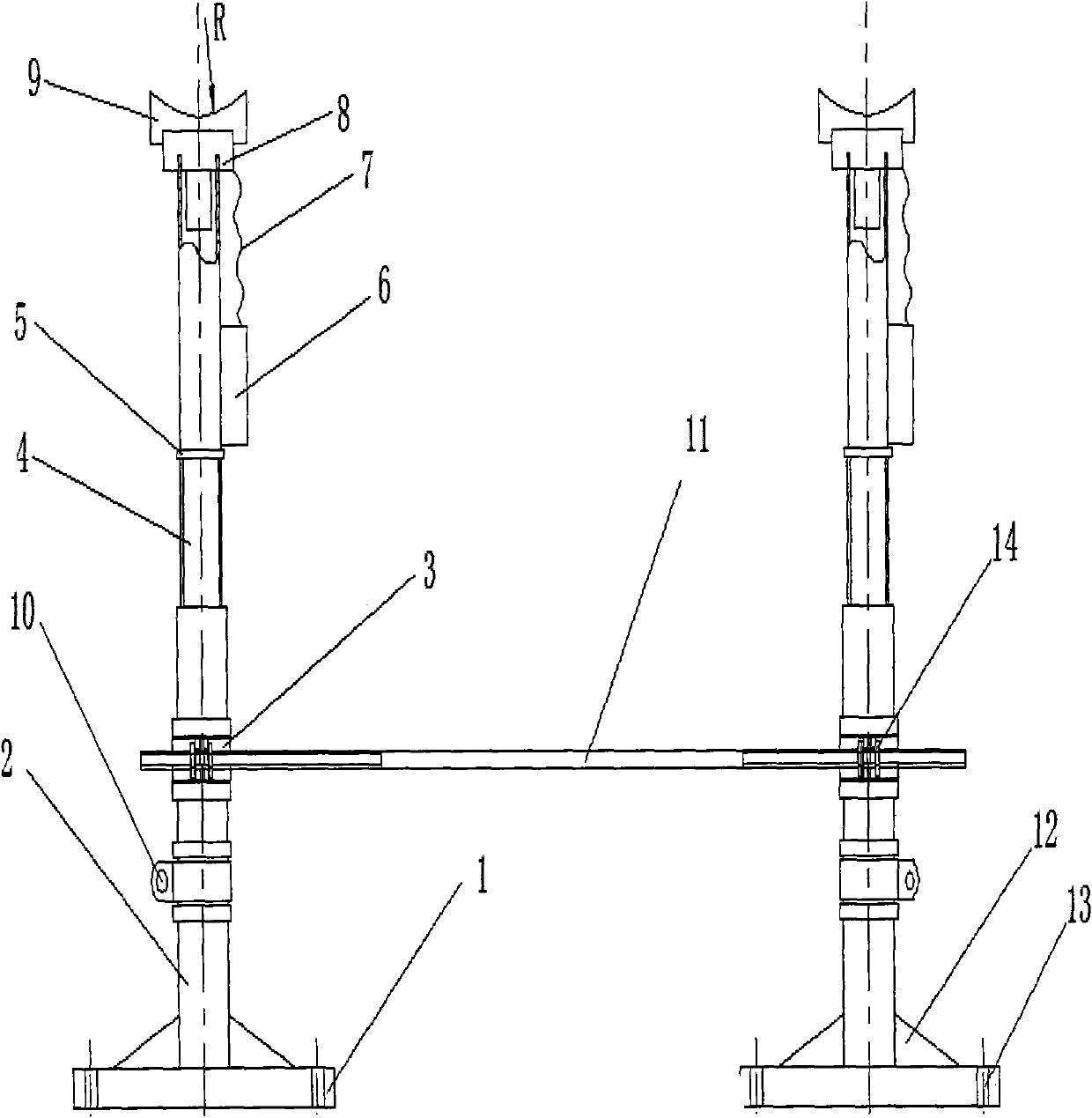

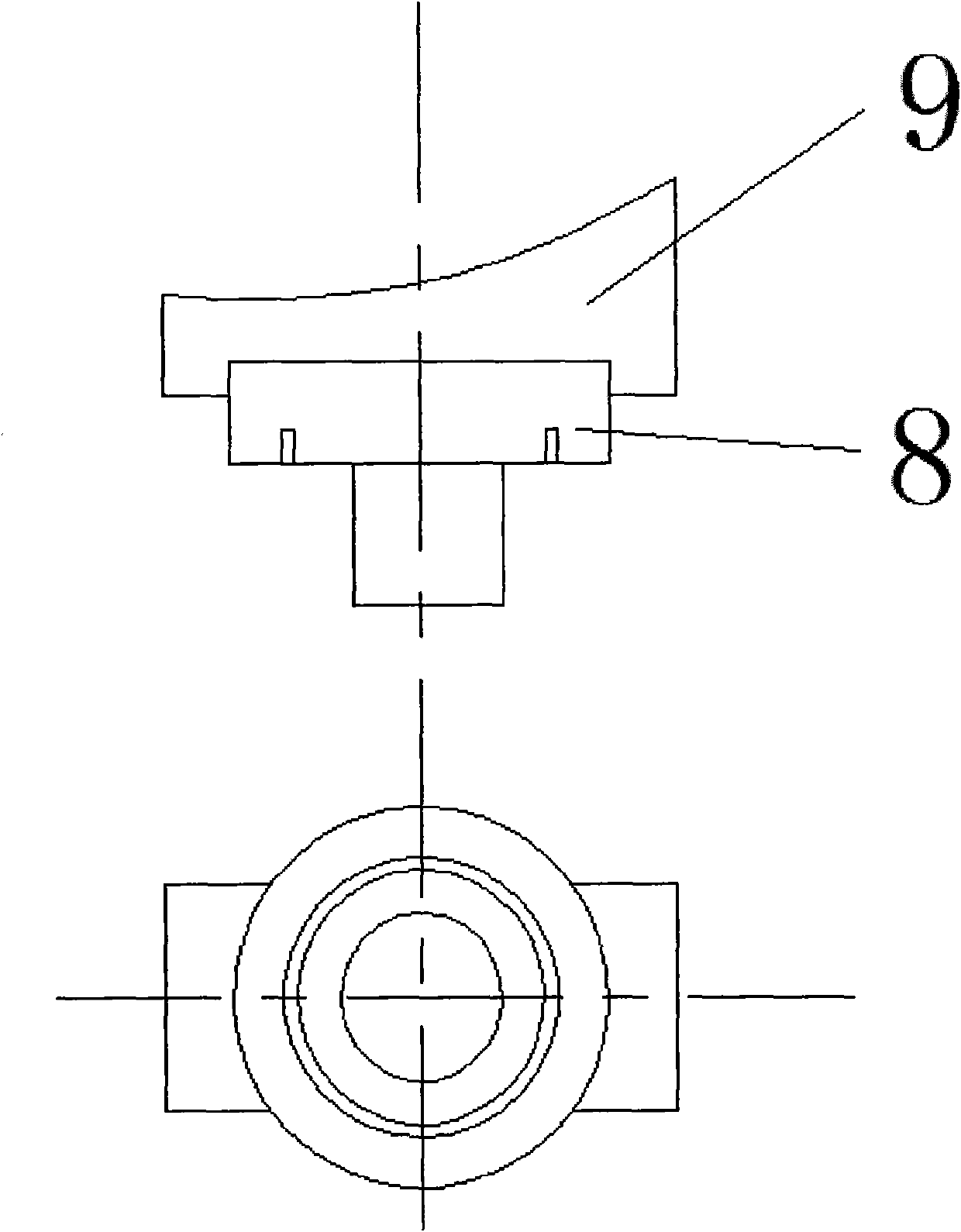

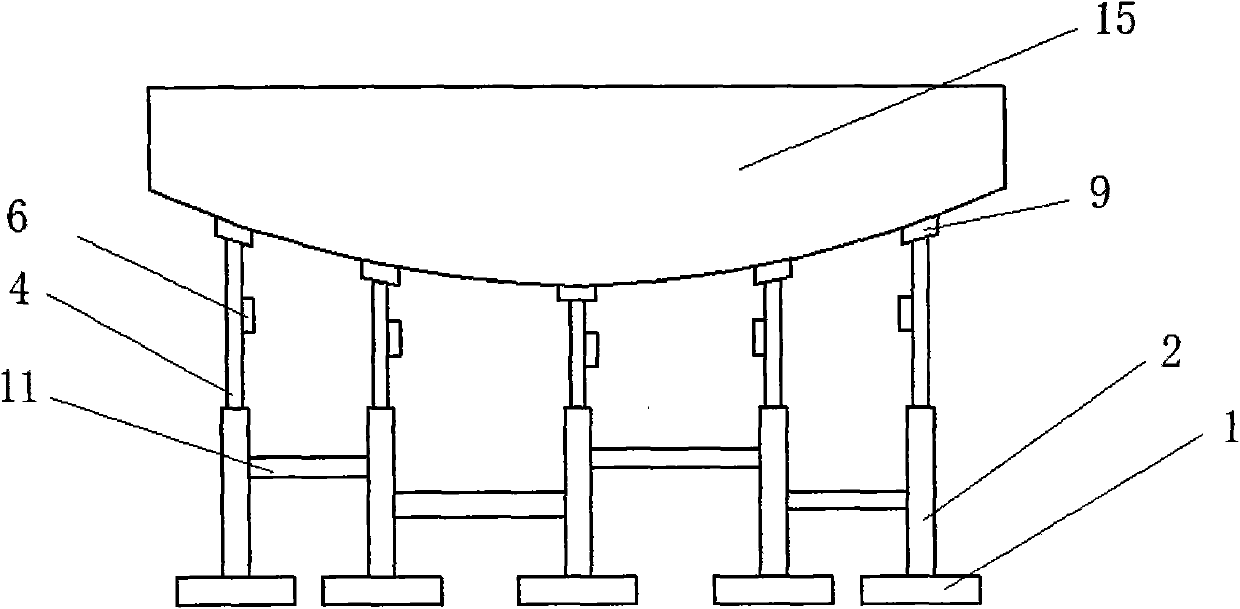

[0027] Such as figure 1 As shown, a freely adjustable electromagnetic adsorption flexible tire frame structure mainly includes: tire frame base 1, tire frame support tube, two connecting ears, protective flange 5, current controller 6, electric wire 7, full-angle Rotary head 8, electromagnetic supporting plate with radian 9, lateral support rod 11, base reinforcement rib 12, wherein the tire frame base 1 is a separate circular flange shape, and the tire frame support tube is divided into an upper spiral tube 4 and a lower spiral tube 2. The tire frame base 1 is connected to the lower spiral tube 2 by welding, and the lower spiral tube 2 is reinforced by the base reinforcement rib 12. There are four threaded holes at 90° each other on the tire frame base 1, which can be connected with other bases if necessary. To connect, the upper sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com