Horizontal pushing automatic feeding slotting machine

An automatic feeding and slotting machine technology, which is applied in container manufacturing machinery, paper/cardboard containers, box production operations, etc., can solve the problems of hidden safety hazards and low efficiency, and achieve high processing efficiency, safe operation, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

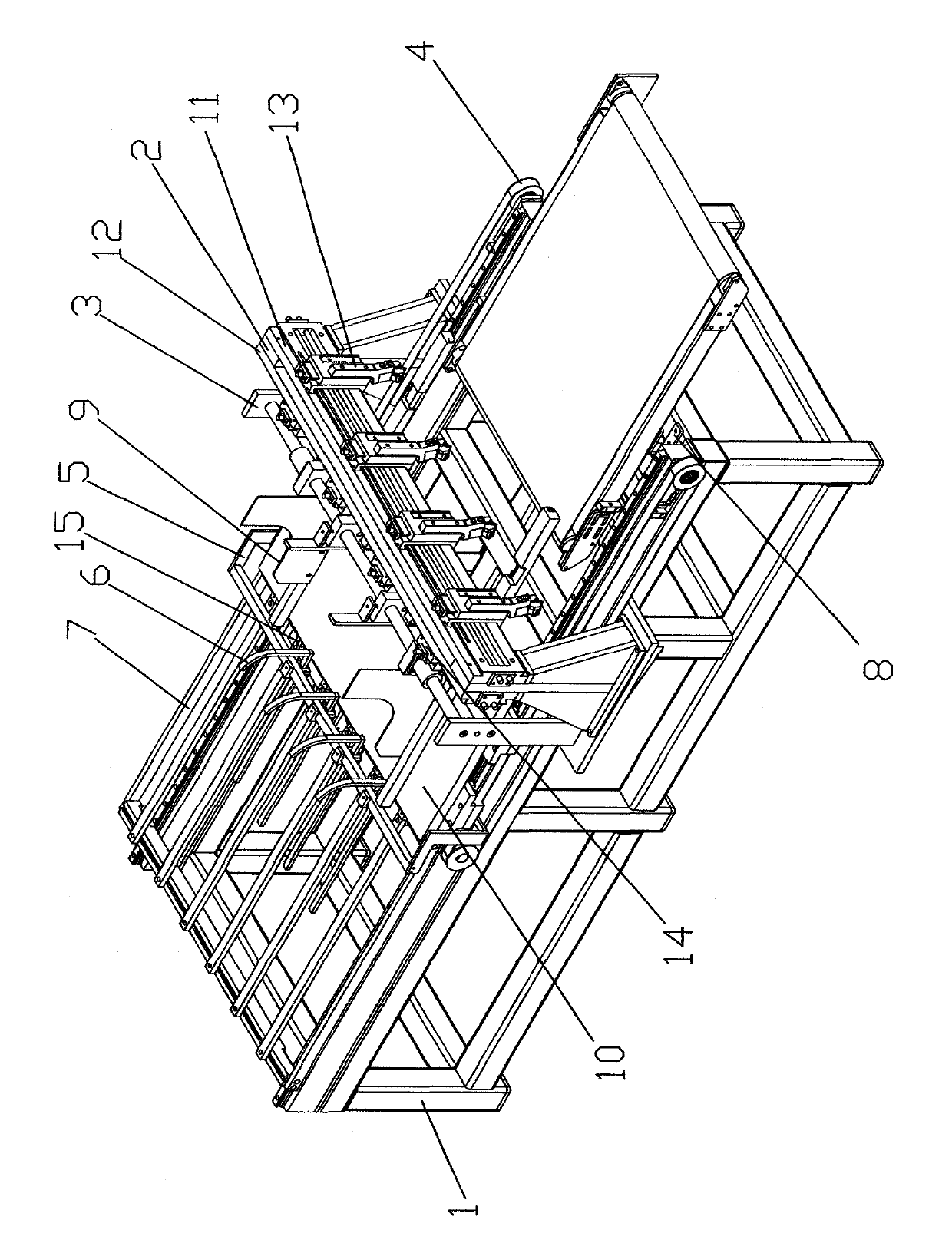

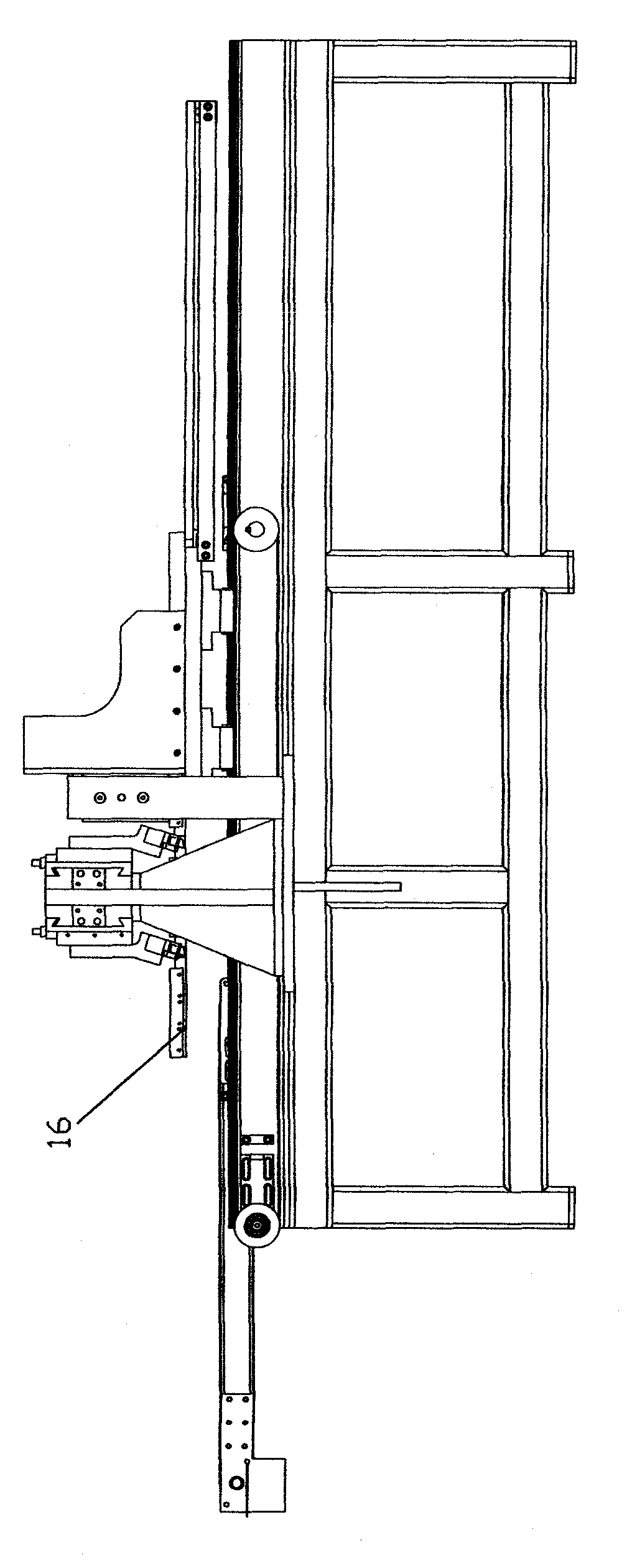

[0015] The total height of the present invention is 1021mm, the total length is 2750mm, and the width is 1021mm; the height of platform 1 is 800mm, the length is 2750mm, and the width is 1200mm; the width of slotted gantry 2 is 1260mm, and the center point of slotted gantry 2 is 1750mm from the front end of platform 1; The gantry 3 is 1200mm wide; the motor of the motor transmission system 4 is a stepping motor of the 1300H2P5050A4 model, the gantry 5 is 80mm high and 50mm wide, and the thrust column 6 is provided with four horn-type thrust columns; each thrust column is spaced at It can be adjusted arbitrarily between 0 and 800mm, and the height is 200mm; the sliding platform 7 is a fence type, 850mm long, 1000mm wide, and 700mm high; the baffle 9 is fixed on the slide rail of the baffle gantry mm through a lockable slider; Platform 10 spans wide 950mm, vertically long 500mm; Push paper knife 15 long 25mm wide 25mm high 15mm;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com