Gluing method by using UV adhesive

A technology of workpiece and ultraviolet light, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of large production cost and production cycle, unsuitable for industrial production, long molding cycle, etc., and achieve high product quality , easy mass production, short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

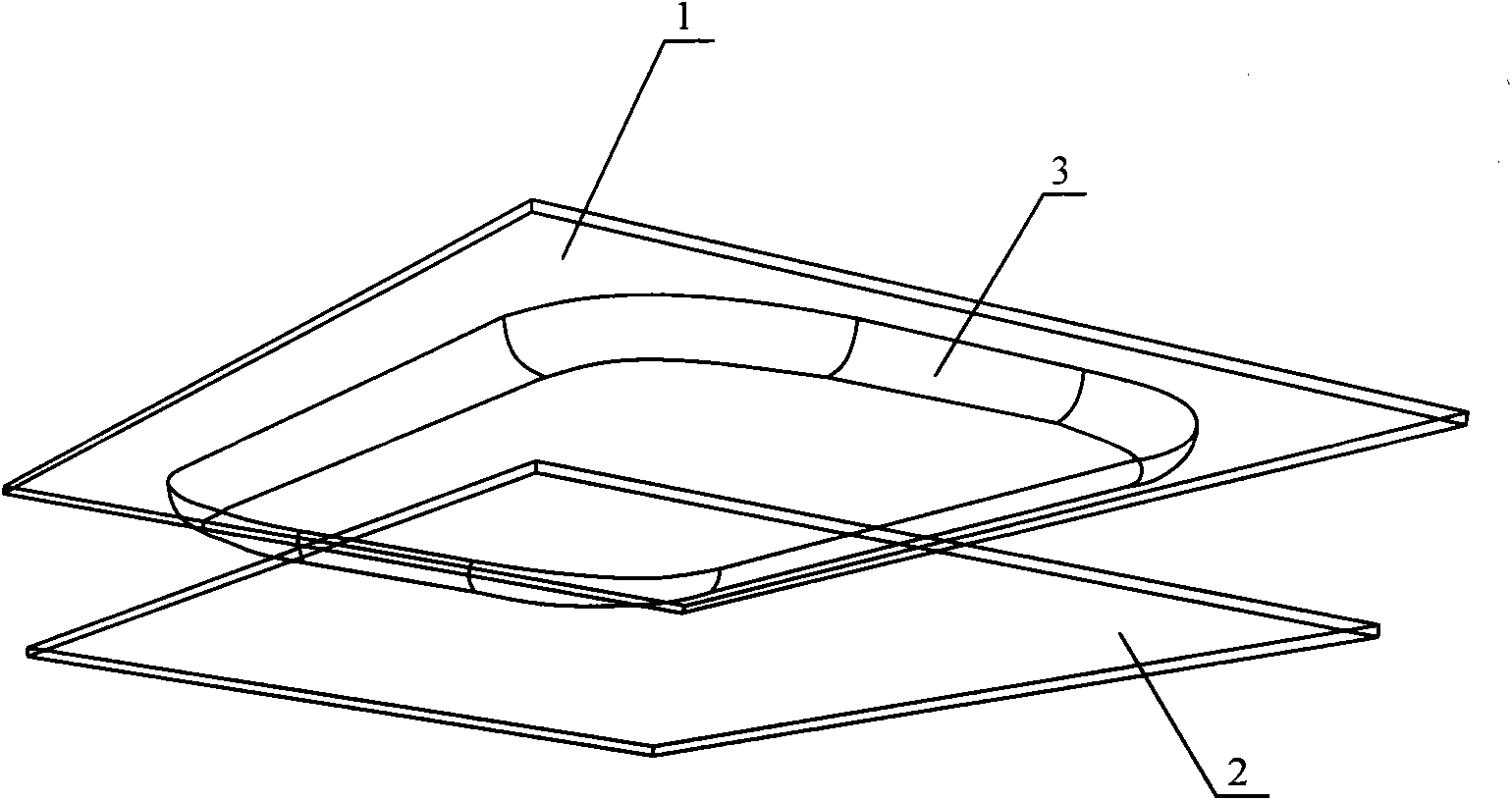

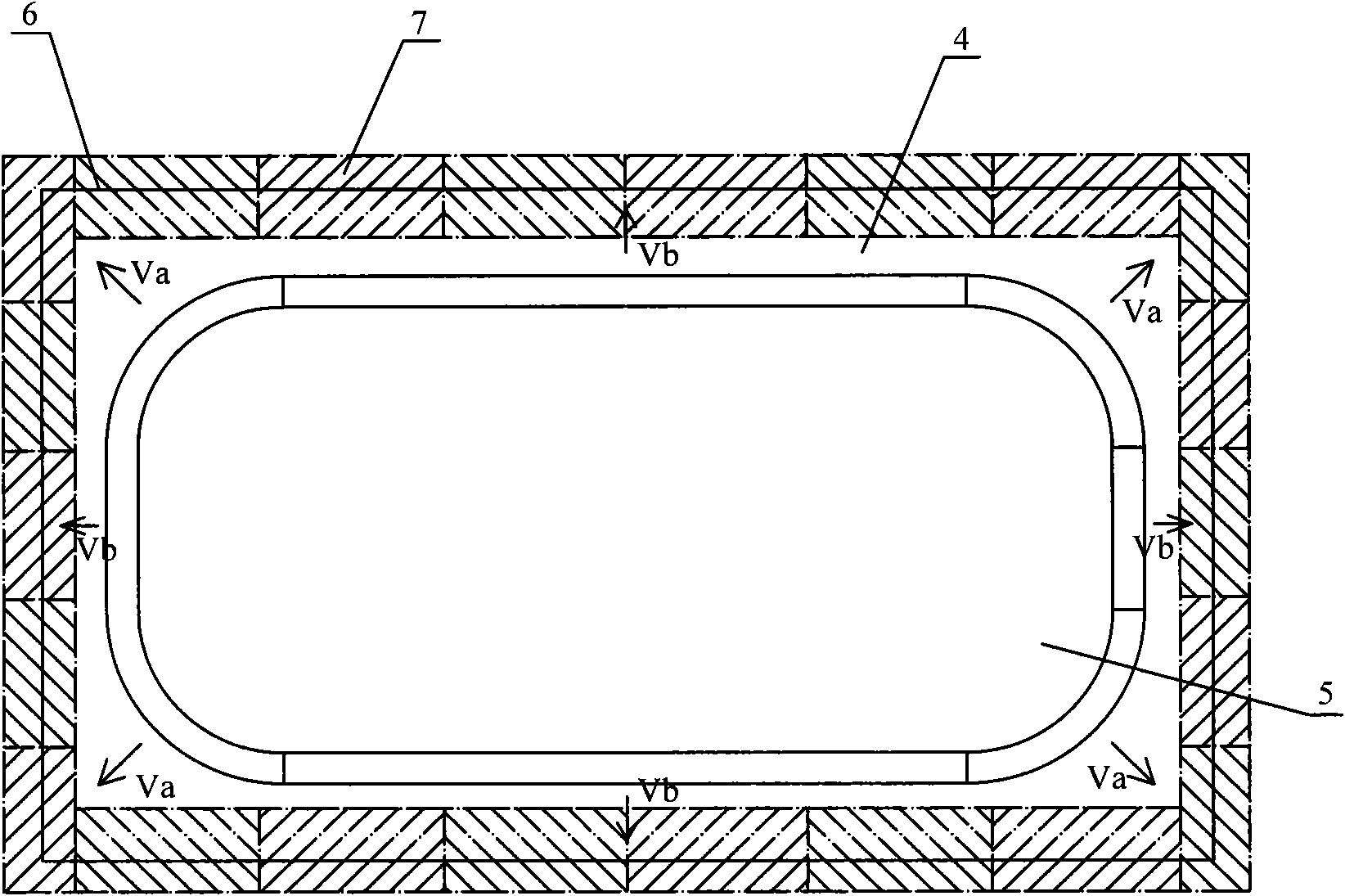

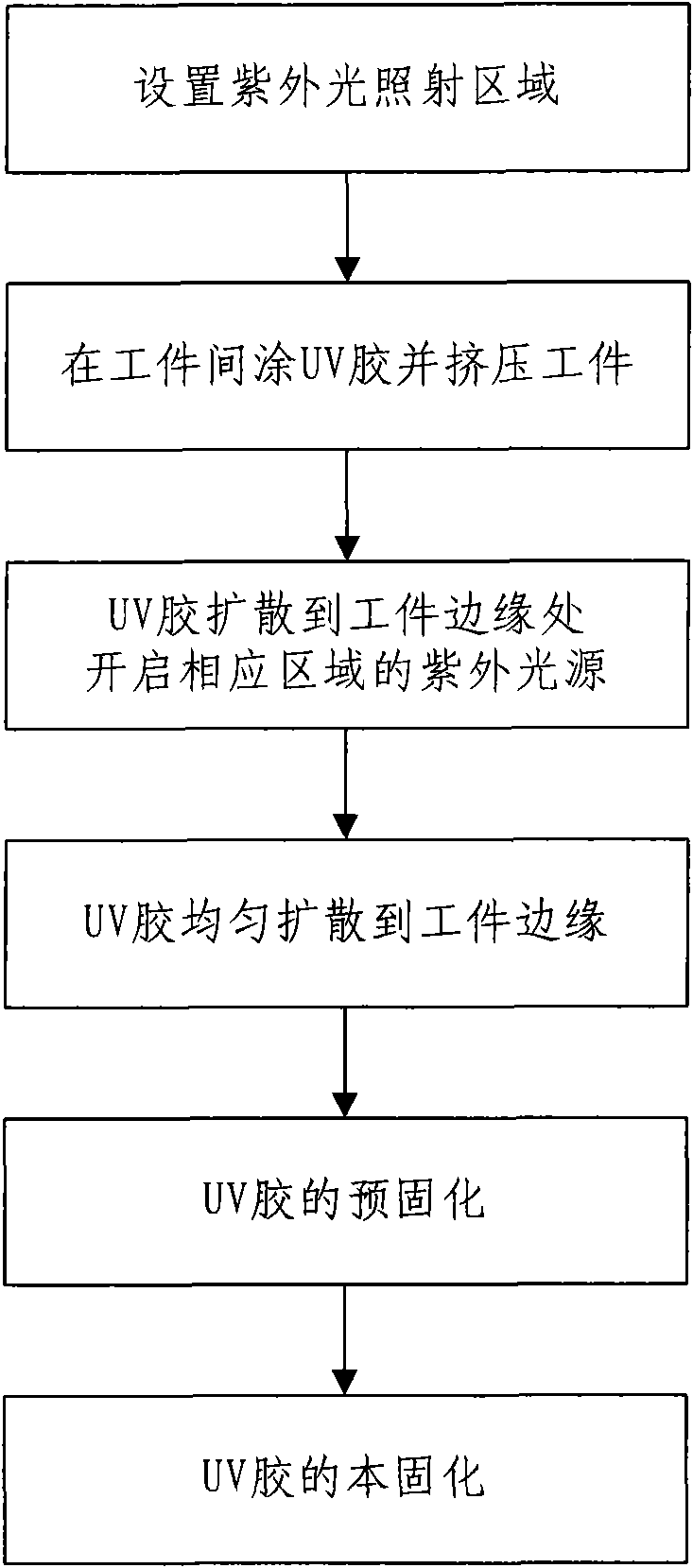

[0024] Such as image 3 shown, see also figure 2 , the UV glue bonding method of the present invention is characterized in that, comprising:

[0025] Setting an ultraviolet light irradiation area 7 on the edge 6 of the workpiece 4;

[0026] Apply UV glue 5 between the workpieces 4, squeeze the workpiece 4 to spread the UV glue 5 around;

[0027] When the UV glue 5 diffuses to the edge area, turn on the corresponding ultraviolet light source in this area, and irradiate the area with ultraviolet light until the UV glue diffuses to each edge of the workpiece and fills the gaps between the workpieces.

[0028] In addition, after the UV glue diffuses to each edge of the workpiece a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap