Belt conveying device for preventing belt from deviating

A technology of belt conveying and belt, which is applied in the field of belt conveying machinery and equipment, can solve the problems of affecting normal work, belt deviation, and poor belt deviation prevention effect, and achieves the effect of simple structure and prevention of belt deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

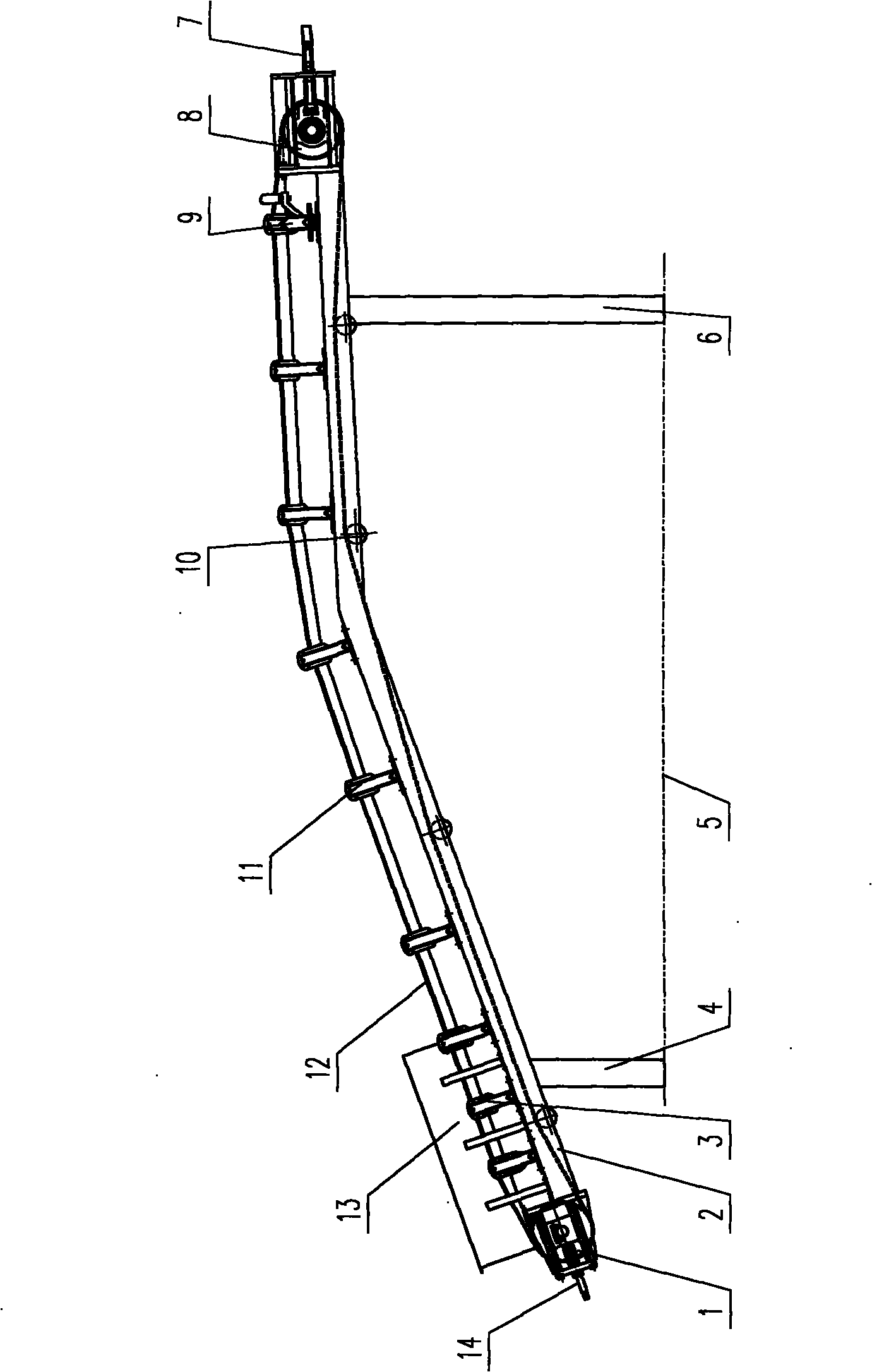

[0016] like figure 1 As shown, it consists of redirecting roller 1, frame 2, upper trough-shaped buffer roller 3, column 4, column 6, head tensioning device 7, driving roller 8, upper trough-shaped self-aligning roller 9, lower parallel support Roller 10, upper trough roller 11, belt 12, feeding baffle 13, tail tensioning device 14 form a conveying device. The belt 12 is an integral ring, and its inner surface is wound on the reversing drum 1, the driving drum 8, the upper grooved buffer idler 3, the upper grooved self-aligning idler 9, and the upper grooved idler 11. Reversing drum 1, driving drum 8, upper trough-shaped buffer idler 3, upper trough-shaped self-aligning idler 9, lower parallel idler 10, and upper trough-shaped idler 11 are all bolted and installed on the frame 2. The belt conveying device is installed on the foundation 5 through a column 4 and a column 6 .

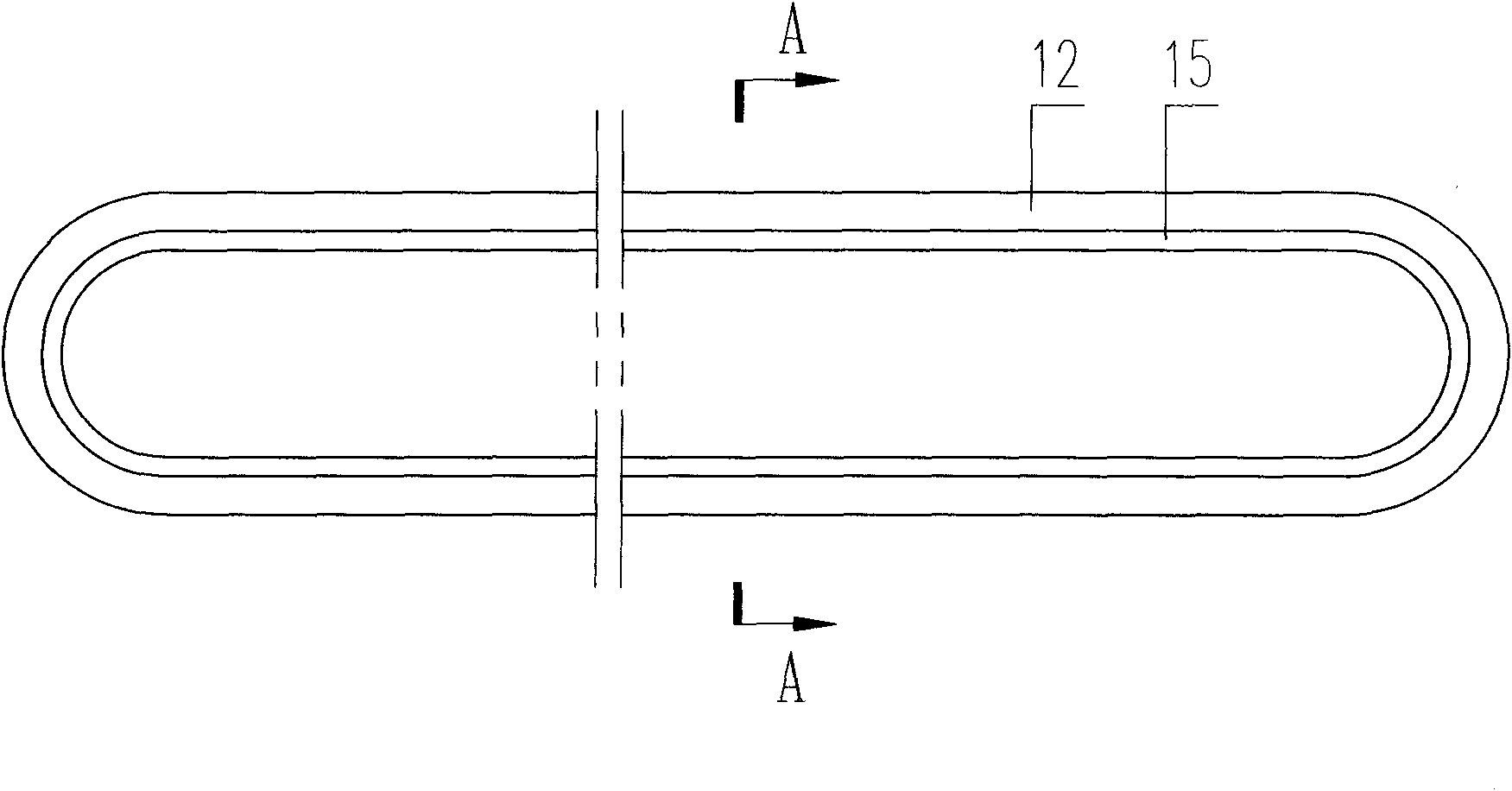

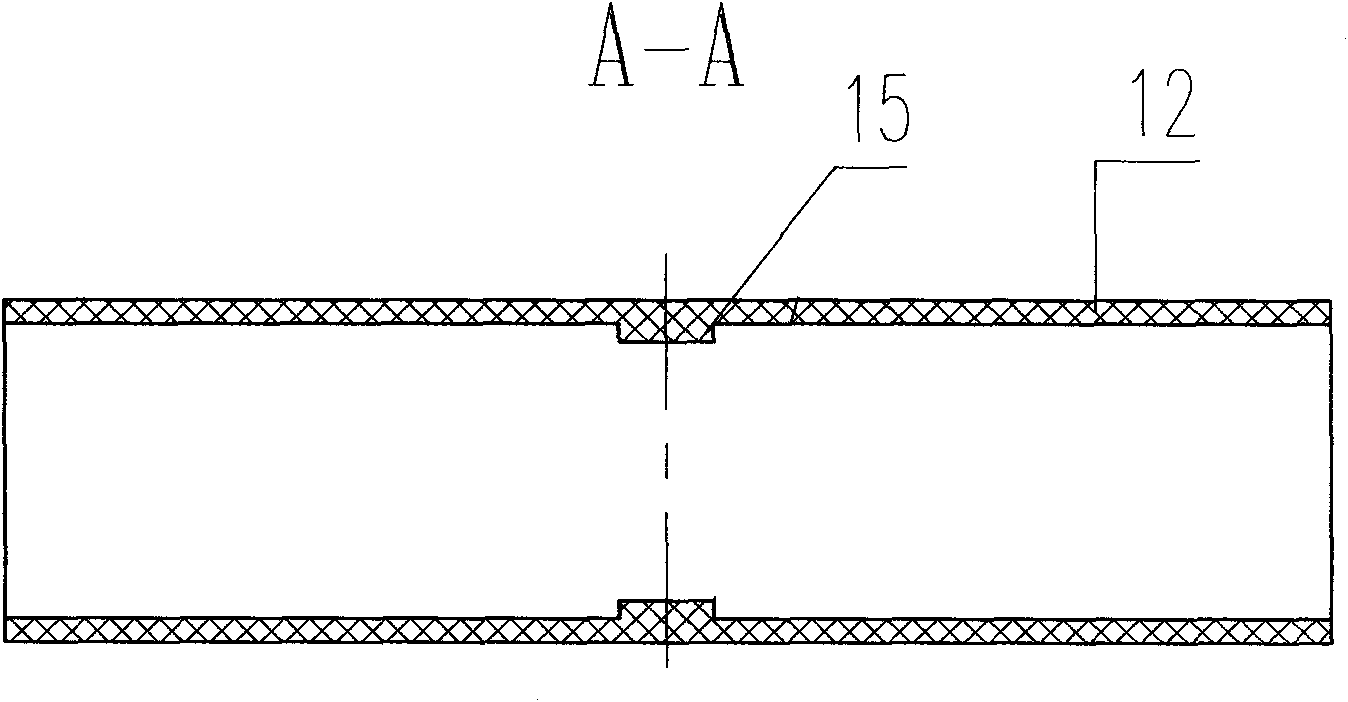

[0017] like figure 2 , image 3 As shown in , a rectangular boss 15 is provided inside the belt 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com