Method for improving tungsten-base gold-plating bond strength

A technology of strength and bonding force, applied in the field of enhancing the bonding strength of gold plating on the surface of tungsten metal, to achieve the effect of easy process parameters and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

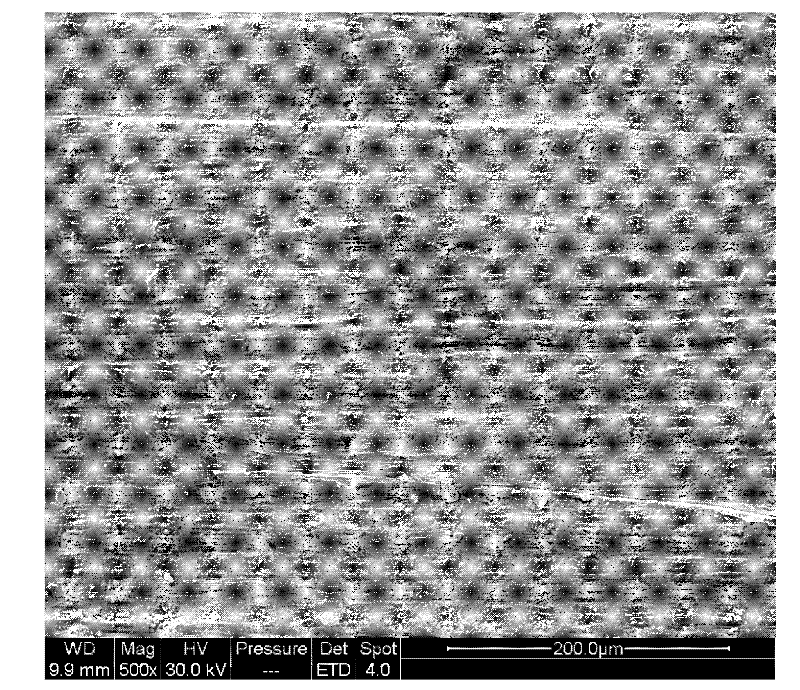

Image

Examples

example 1

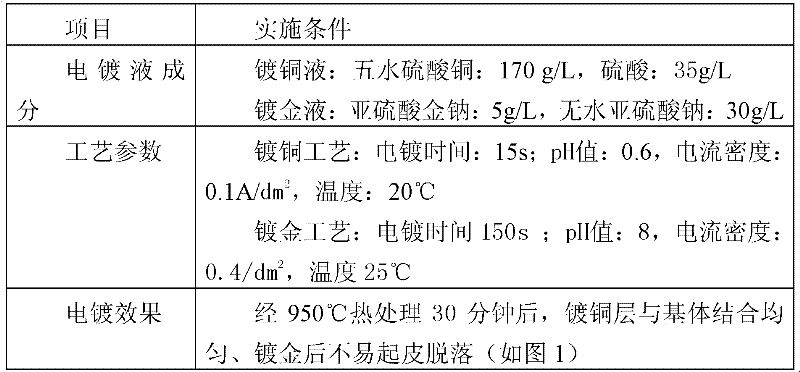

[0016] Example 1: prepare according to the composition of the electroplating solution in Table 1, adjust the electroplating time to 15s, and then electroplate the copper transition layer according to the above process steps.

[0017] Table 1 specific implementation conditions

[0018]

example 2

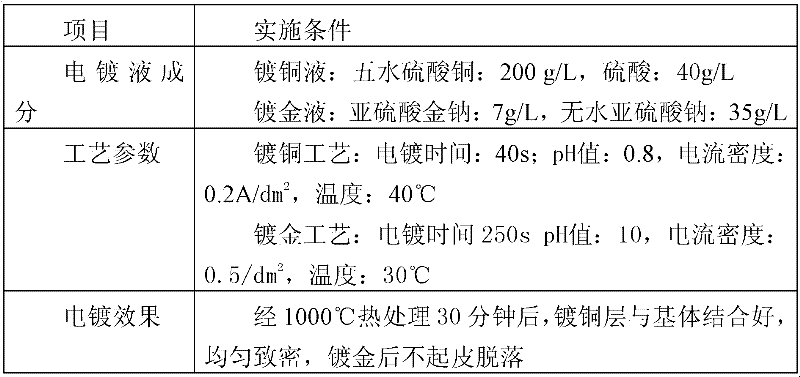

[0020] Example 2: prepare according to the composition of the electroplating solution in Table 2, adjust the electroplating time to 40s, and then electroplate the copper transition layer according to the above process steps.

[0021] Table 2 specific implementation conditions

[0022]

example 3

[0023] Example 3: Prepare according to the composition of the electroplating solution in Table 3, adjust the electroplating time to 120s, and then press

[0024] Electroplate the copper transition layer according to the above process steps.

[0025] Table 3 specific implementation conditions

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com