Fabric for safety air bag

A technology for airbags and fabrics, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of anti-slippage at the seam of airbag fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

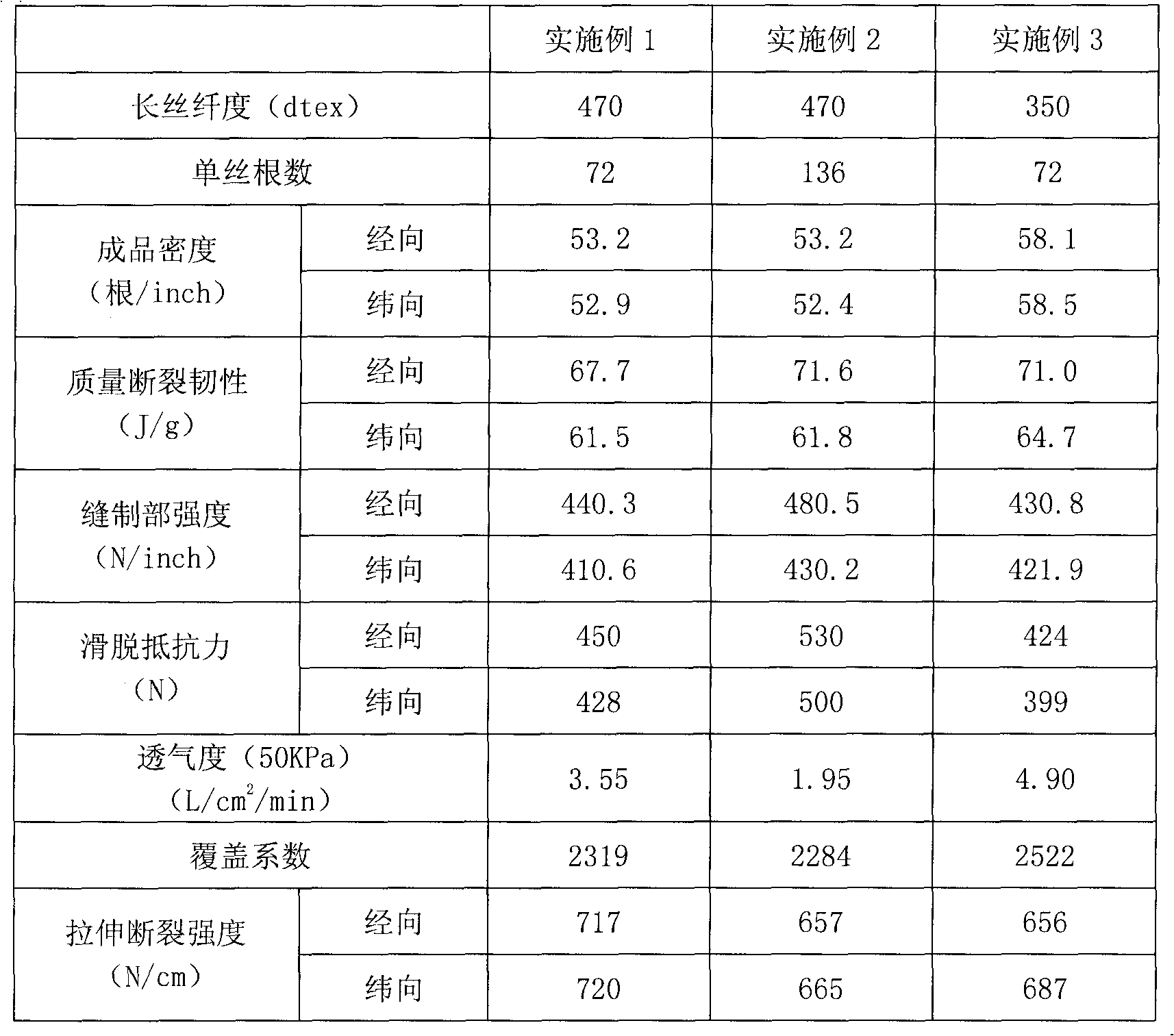

[0043] Nylon 66 filaments with a fineness of 470dtex, a number of single filaments of 72f, and a circular cross section are used to weave a plain weave fabric with a warp and weft density of 53 threads / inch×53 threads / inch by a water jet loom, and after drying, pass through 180 ℃ × 36s heat-setting post-processing, the airbag fabric of the present invention is obtained, and the evaluation results of its various performance parameters are shown in Table 1.

Embodiment 2

[0045]Nylon 66 filaments with a fineness of 470dtex, a number of single filaments of 136f, and a circular cross section are used to weave a plain weave fabric with a warp and weft density of 53 threads / inch×53 threads / inch with a water jet loom, and after drying, pass through 180 ℃ × 36s heat-setting post-processing, the airbag fabric of the present invention was obtained, and the evaluation results of its various performance parameters are shown in Table 1.

Embodiment 3

[0047] Nylon 66 filaments with a fineness of 350dtex, a number of single filaments of 72f, and a circular cross section were used to weave a plain weave fabric with a warp and weft density of 58 / inch×58 / inch by a water-jet loom. After drying, this product was obtained. The evaluation results of various performance parameters of the invented airbag fabric are shown in Table 1.

[0048] Table 1

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com